Graphitized carbon-based adsorption material as well as preparation method and application thereof

An adsorption material and graphitization technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of affecting the selectivity and adsorption recovery rate of target compounds, increasing the content of metal elements, and complex preparation processes. The effect of low energy cost, low preparation temperature and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 10g of thermoplastic phenol-formaldehyde resin in a vacuum tube furnace, heat continuously at a rate of 10°C / min to 1200°C under nitrogen, keep the temperature for 3 hours, and continuously lower it to room temperature at a rate of 10°C / min to obtain 5g of crude product , Grinding and sieving to obtain 50-60 mesh black granular products.

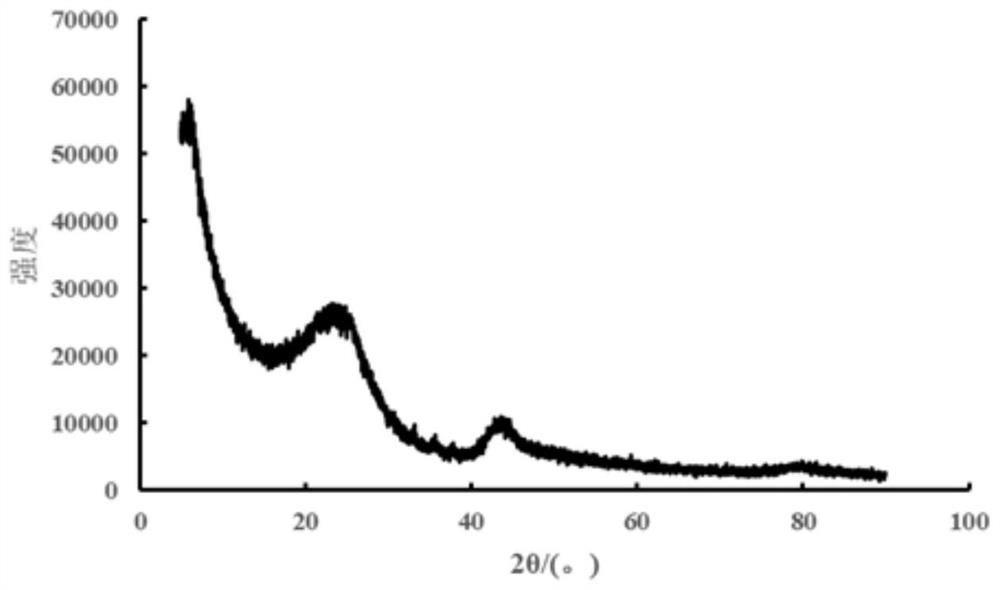

[0027] The prepared carbon material has a specific surface area of 100m 2 / g, using X-ray diffraction to observe the structure of materials, see figure 1 ,Depend on figure 1 It can be seen that after the carbon material is heat-treated, the diffraction peaks at 2θ=25.5° and 43.2° are the diffraction peaks of the C(002) and C(100) crystal planes, indicating that the interplanar distance d(002) of the (002) crystal plane decreases Small, the degree of ordering and graphitization of carbon materials increases.

Embodiment 2

[0029] Weigh 20g of thermoplastic phenol-formaldehyde resin in a vacuum tube furnace, heat continuously at a rate of 5°C / min to 1400°C under argon gas, keep the temperature for 2 hours, and then cool down to room temperature at a rate of 20°C / min to obtain the crude product 9.0g, grinded and sieved to obtain 60-80 mesh black granular products.

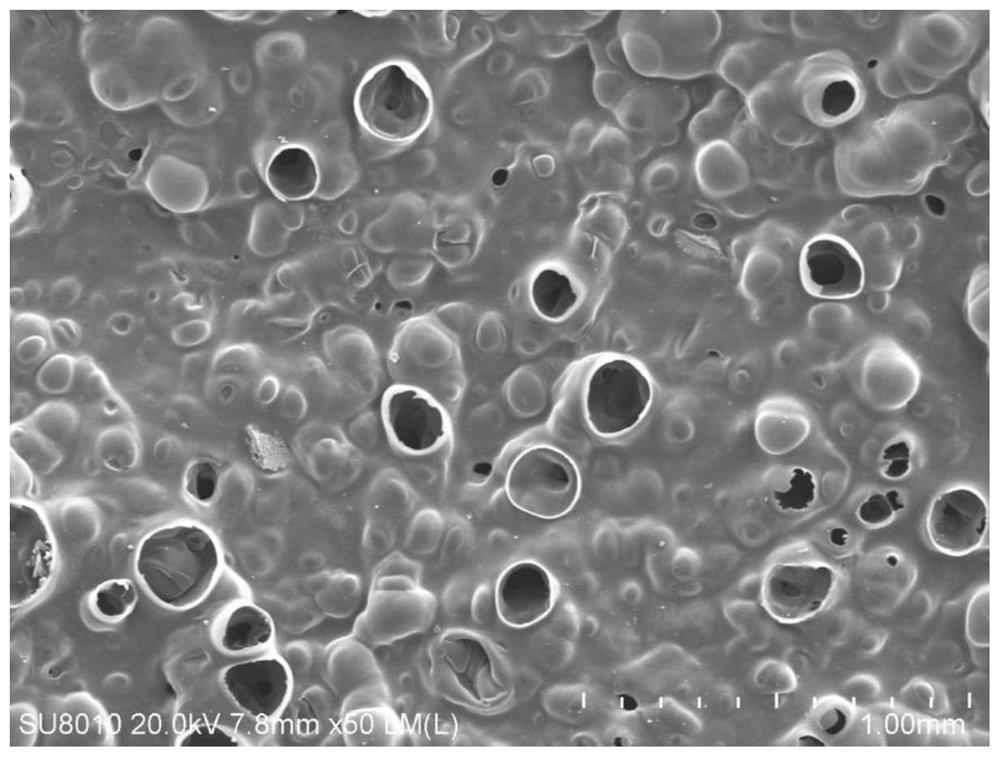

[0030] The prepared carbon material has a specific surface area of 20m 2 / g, using scanning electron microscopy to observe the structure of the material, see figure 2 ,Depend on figure 2 It can be seen that an obvious graphitized sheet structure appears on the surface of the carbon material, indicating that high-temperature heat treatment improves the degree of ordering of the carbon material, and the appearance of concentric rings indicates that the material has a high degree of graphitization after high-temperature treatment.

Embodiment 3

[0032] Weigh 5g of thermoplastic phenol-formaldehyde resin in a vacuum tube furnace, heat it up to 1600°C at a rate of 20°C / min under nitrogen, and then cool it down to room temperature at a rate of 30°C / min for 1 hour. The obtained crude product is 2.0 g, after grinding and sieving to obtain 80-100 mesh black granular products.

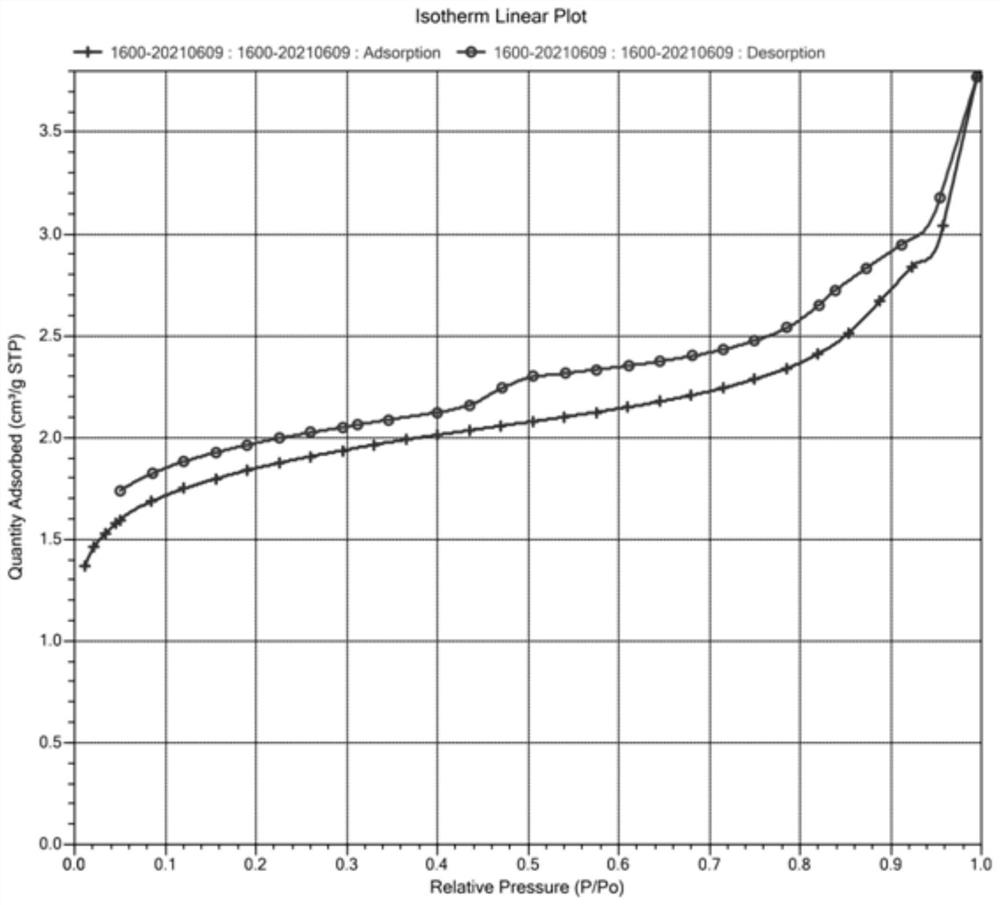

[0033] The prepared carbon material has a specific surface area of 10m 2 / g, nitrogen adsorption / desorption isotherm diagram see image 3 . According to the calculation of the isotherm, the specific surface area of the carbon material reaches 10m after high-temperature heat treatment. 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com