Anti-enzymolysis collagen compound and application thereof

A technology of collagen and peptide collagen, which is applied in the field of anti-enzyme collagen complexes, can solve the problems of unfavorable popularization and use of collagen pharmaceutical products, high cost of collagen pharmaceutical products, and short half-life, so as to promote the improvement of chronic wounds. Effects of healing or tissue repair, reduction of collagenase activity, reduction of decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

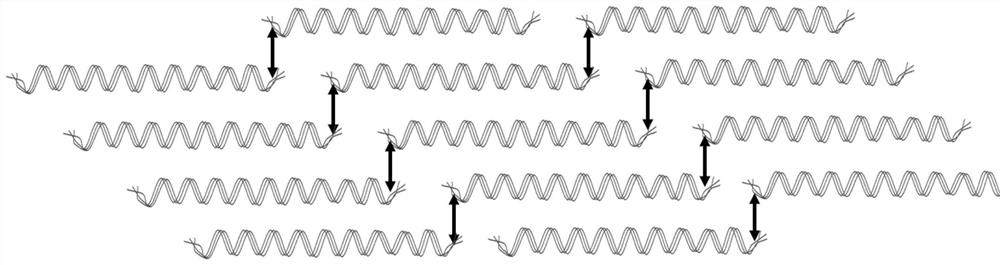

Image

Examples

Embodiment 1

[0061] Embodiment 1: Anti-enzymolysis ability test 1

[0062] (1) Dissolve type A gelatin in warm water, prepare 10% (w / v) gelatin solution, add 5% (w / v) ethylenediaminetetraacetic acid disodium salt (hereinafter referred to as EDTA) and stir until dissolved;

[0063] (2) Add 5ml EDTA-gelatin solution to 100ml 45°C preheated soybean oil, stir at 13,000rpm for 15-20 minutes;

[0064] (3) Add ice water and continue to stir for 10-15 minutes, and remove most of the supernatant after standing;

[0065] (4) Wash the EDTA-gelatin microspheres several times with pre-cooled acetone at 4°C and air-dry them;

[0066] (5) 0.5% (w / v) glutaraldehyde was added to EDTA-gelatin microspheres, and cross-linked at 50°C for 6 hours;

[0067] (6) Wash the cross-linked gelatin microspheres several times with purified water, sieve and select 10–50 μm microspheres after drying;

[0068] (7) Dissolve 1g of porcine atelocollagen in 0.1N hydrochloric acid, adjust the pH to pH 7 with 1N NaOH, adjust the...

Embodiment 2

[0073] Embodiment 2: Anti-enzymolysis ability test 2

[0074] (1) Dissolving gelatin in warm water, preparing 10% (w / v) gelatin solution, adding 10% (w / v) ethylenediaminetetraacetic acid disodium salt (hereinafter referred to as EDTA) and stirring until dissolved;

[0075] (2) Add 10ml of EDTA-gelatin solution to 100ml of 55°C preheated mineral oil containing 1% (w / v) sorbitan monooleate, and stir at 2,400rpm;

[0076] (3) After the solution is cooled to room temperature, move the solution to an ice bath and continue to stir, and leave to remove the supernatant;

[0077] (4) Wash the EDTA-gelatin microspheres several times with pre-cooled acetone at 4°C and air-dry them;

[0078] (5) Add 0.5% (w / v) glutaraldehyde solution to EDTA-gelatin microspheres, and cross-link at 40°C for 12 hours;

[0079] (6) Wash the cross-linked gelatin microspheres several times with purified water, sieve and select 10–50 μm microspheres after drying;

[0080] (7) Dissolve 1g bovine atelocollagen...

Embodiment 3

[0085] Embodiment 3: Anti-enzymolysis ability test 3

[0086] (1) Dissolve the recombinant human type III collagen in warm water 0.1N hydrochloric acid, adjust the pH to pH7 with 1N NaOH, prepare 2% (w / v) gelatin solution, add 2.5% (w / v) doxyl hydrochloride Cyclocycline (hereinafter referred to as DOX) is stirred until dissolved;

[0087] (2) Add 5ml DOX-gelatin solution to 100ml soybean oil preheated at 45°C, and stir at 13,000rpm for 15-20 minutes;

[0088] (3) Add ice water and continue to stir for 10-15 minutes, then remove the supernatant after standing still;

[0089] (4) Wash the DOX-gelatin microspheres several times with pre-cooled acetone at 4°C and air-dry them;

[0090] (5) Add 0.5% (w / v) glutaraldehyde to DOX-gelatin microspheres, and cross-link at 50°C for 6 hours;

[0091] (6) Wash the cross-linked gelatin microspheres several times with purified water, sieve and select 10–50 μm microspheres after drying;

[0092] (7) Dissolve 1g of human type I collagen in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com