Copper/high-carbon steel composite material as well as special V-shaped gas protection cover, laser-assisted preparation method and application thereof

A composite material, high carbon steel technology, applied in laser welding equipment, metal rolling, manufacturing tools, etc., can solve the problems that restrict the mass production and application of copper/high carbon steel composite strips, large rolling deformation, and large restrictions Mass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

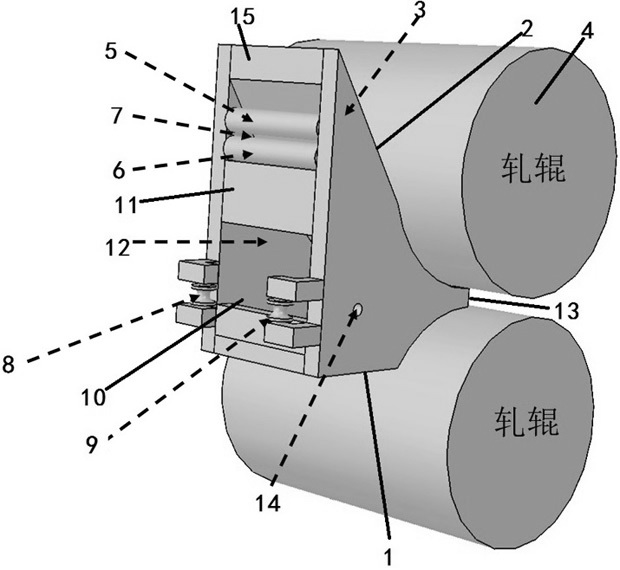

[0053] Such as figure 2 As shown, a special V-shaped gas shield for copper / high carbon steel composite materials, including a V-shaped shell 3 surrounded by a base plate 1, a cladding plate 2 and side plates;

[0054] The outer walls of the base plate 1 and the cladding plate 2 are provided with arc-shaped grooves adapted to the roll 4;

[0055] The upper limit roller 5 and the lower limit roller 6 are arranged on the inlet end 15 of the V-shaped shell 3 close to the cover plate 2, and the gap between the upper limit roller 5 and the lower limit roller 6 is the copper strip inlet 7 ;

[0056] The V-shaped housing 3 is provided with a left limit wheel 8 and a right limit wheel 9 on the inlet end 15 close to the base plate 1; between the left limit wheel 8 and the right limit wheel 9 is high carbon steel Take entrance 10;

[0057] The inlet end 5 is provided with a baffle 11 close to the lower limit roller 6;

[0058] Below the baffle 11 is a laser irradiation window 12;

...

Embodiment 2

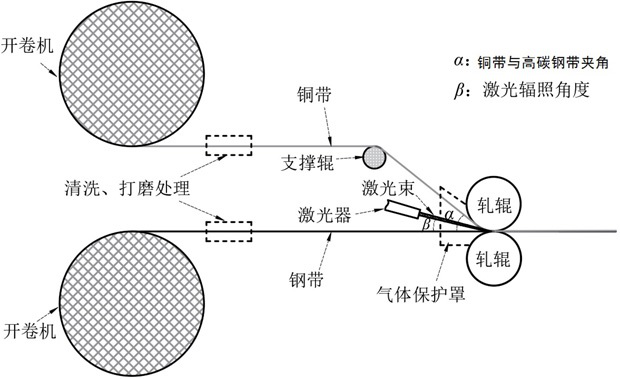

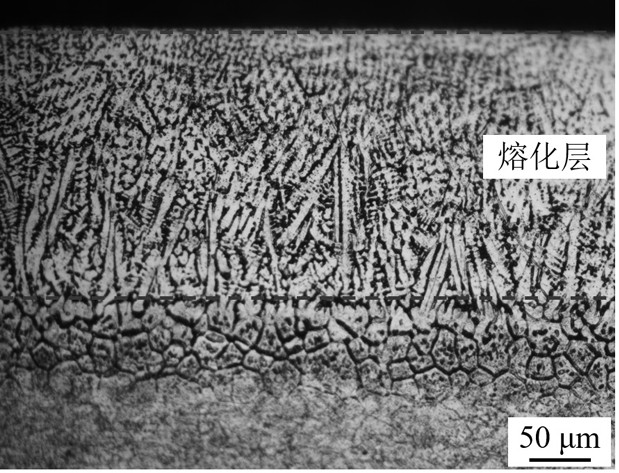

[0066] A laser-assisted preparation method of a copper / high carbon steel composite material, comprising the following steps: cleaning and polishing the surface to be bonded of a copper strip with a thickness of 0.3 mm and a high carbon steel strip with a thickness of 1.2 mm, and the laser energy density is 120 W / mm 2 , the laser irradiation angle is 15°, the angle between the copper strip and the high carbon steel strip is 45°, the laser spot size is width×length=3×10 mm, the rolling deformation is 2%, and the rolling speed is 25 mm / s, the nitrogen flow rate was 5 L / min. Rolling deformation forms an eddy current zone at the interface of the molten layer, and then produces a copper-steel transition layer at a local location, and finally obtains a copper / high-carbon steel composite strip with a well-bonded interface. The microstructure of the bonding interface after rolling is as follows: Figure 6 As shown, there is a transition layer at the local position of the bonding int...

Embodiment 3

[0068] A laser-assisted preparation method of a copper / high carbon steel composite material, comprising the following steps: cleaning and polishing the surface to be bonded of a copper strip with a thickness of 0.3 mm and a high carbon steel strip with a thickness of 1.2 mm, and the laser energy density is 120 W / mm 2 , the laser irradiation angle is 15°, the angle between the copper strip and the high carbon steel strip is 45°, the laser spot size is 3×10 mm, the rolling deformation is 2%, the rolling speed is 20 mm / s, and the nitrogen flow rate is 5 L / min, so that the surface of the high-carbon steel strip at the interface to be bonded produces a molten layer with a thickness of 200 μm. The microstructure of the bonding interface after rolling is as follows: Figure 7 As shown, there is a transition layer at the local position of the bonding interface, without holes, and the bonding is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com