Organic montmorillonite modified flame-retardant PC material and preparation method thereof

An organic montmorillonite and organic technology, applied in the field of flame-retardant PC materials and its preparation, can solve the problems of high flame-retardant efficiency, uneven dispersion of boron compounds and siloxane, and low decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

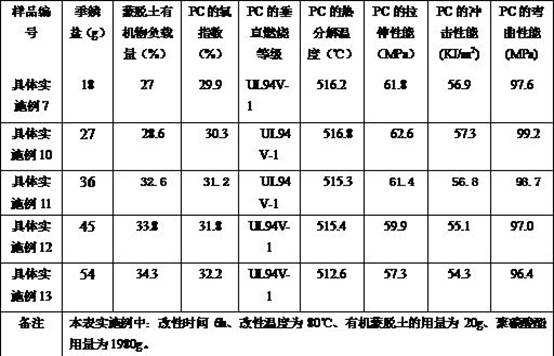

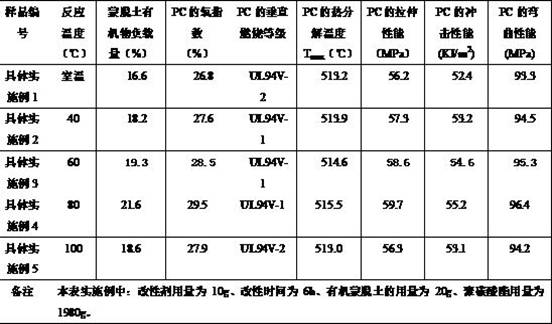

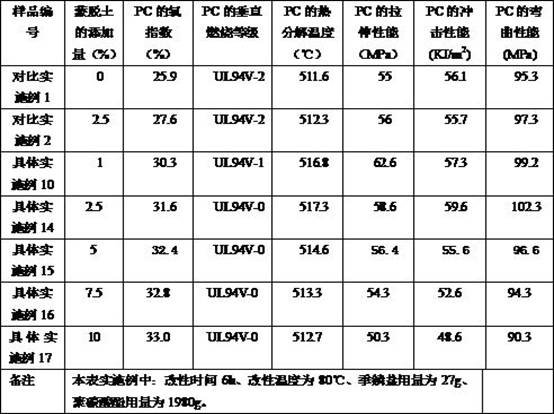

Examples

specific Embodiment 1

[0022] (1) Add 45g of sodium-based montmorillonite into a beaker filled with 800mL of distilled water, and keep stirring for 30min until the montmorillonite is evenly dispersed. The beaker containing the suspension was subjected to ultrasonic dispersion for 30 minutes, and left to stand for 5-10 minutes after the ultrasonic dispersion was completed to remove the sediment at the bottom. Then 18 g of hydroxyhexyltriphenylphosphorus chloride was added, and after ultrasonic dispersion for 30 min, the mixture was stirred and reacted at room temperature for 4 h, filtered with suction, and washed with distilled water until there was no chloride ion. Add 400mL of distilled water for ultrasonic dispersion, and dry with a spray dryer to prepare organically modified montmorillonite;

[0023] (2) Blend 20g of the organically modified montmorillonite prepared in step (1) with 1980g of PC resin with a high-speed mixer, melt extrude with a twin-screw extruder, granulate, and dry to obtain PC w...

specific Embodiment 2

[0025] (1) Add 45g of sodium-based montmorillonite into a beaker filled with 800mL of distilled water, and keep stirring for 30min until the montmorillonite is evenly dispersed. The beaker containing the suspension was subjected to ultrasonic dispersion for 30 minutes, and left to stand for 5-10 minutes after the ultrasonic dispersion was completed to remove the sediment at the bottom. Then 18 g of hydroxyhexyltriphenylphosphorus chloride was added, and after ultrasonic dispersion for 30 min, the mixture was stirred and reacted at room temperature for 4 h, filtered with suction, and washed with distilled water until there was no chloride ion. Add 400mL of distilled water for ultrasonic dispersion, and dry with a spray dryer to prepare organically modified montmorillonite;

[0026] (2) Blend 20g of the organically modified montmorillonite prepared in step (1) with 1980g of PC resin with a high-speed mixer, melt extrude with a twin-screw extruder, granulate, and dry to obtain PC...

specific Embodiment 3

[0028] (1) Add 45g of sodium-based montmorillonite into a beaker filled with 800mL of distilled water, and keep stirring for 30min until the montmorillonite is evenly dispersed. The beaker containing the suspension was subjected to ultrasonic dispersion for 30 minutes, and left to stand for 5-10 minutes after the ultrasonic dispersion was completed to remove the sediment at the bottom. Then 18 g of hydroxyhexyltriphenylphosphorus chloride was added, and after ultrasonic dispersion for 30 min, the mixture was stirred and reacted at room temperature for 4 h, filtered with suction, and washed with distilled water until there was no chloride ion. Add 400mL of distilled water for ultrasonic dispersion, and dry with a spray dryer to prepare organically modified montmorillonite;

[0029] (2) Blend 20g of the organically modified montmorillonite prepared in step (1) with 1980g of PC resin with a high-speed mixer, melt extrude with a twin-screw extruder, granulate, and dry to obtain PC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com