Process and equipment for removing fusel oil in Baijiu by composite plant enzyme method

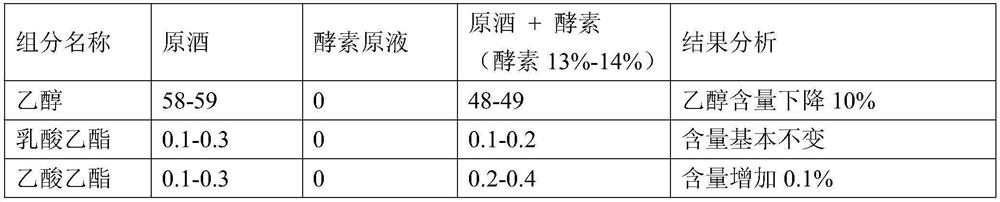

A plant enzyme and compound technology, which is applied in the field of technology and equipment for removing fusel oil in liquor by compound plant enzyme method, can solve the problems of undisclosed liquor ingredients, changes, and restrictions on the amount of enzyme added, and achieve good dissolution effect, Headache relief, soft taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

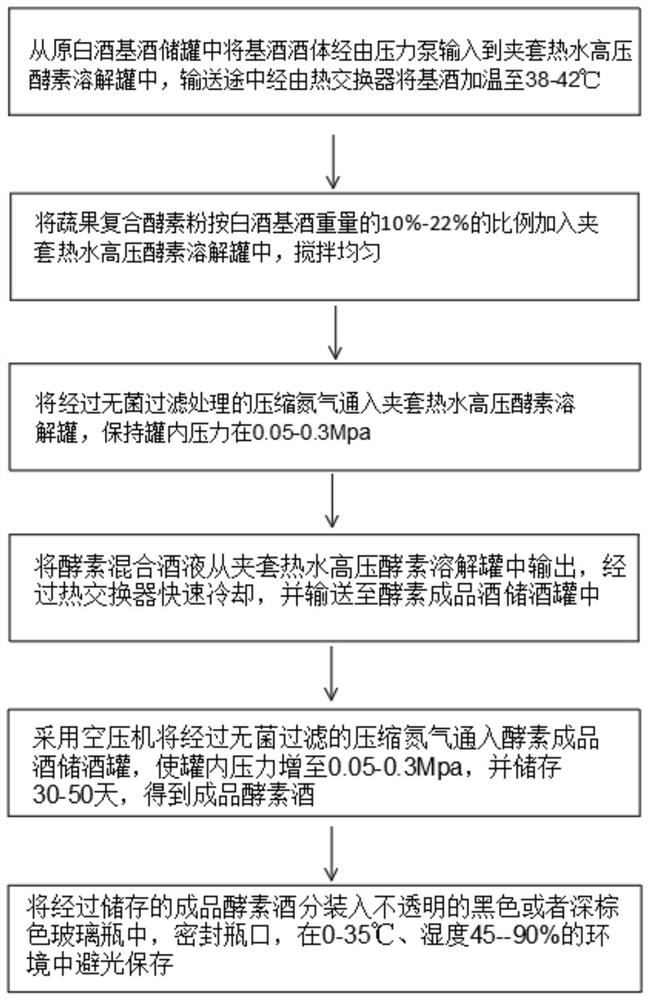

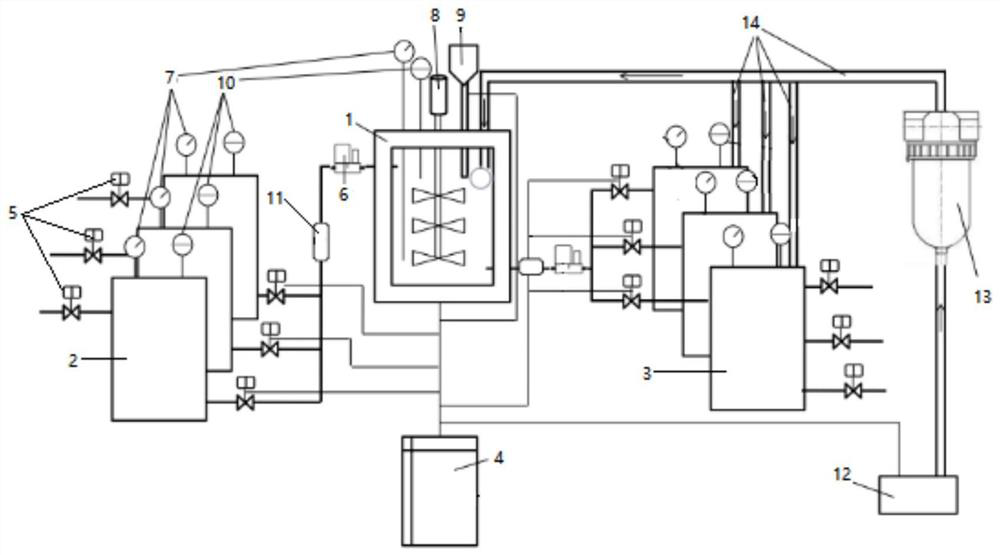

[0041] Step 1: The fragrance-flavored liquor in the original liquor base liquor storage tank is input into the jacketed hot water high-pressure enzyme dissolving tank 1 through pressure, and the liquor is rapidly heated to 40°C±2 through a heat exchanger during the transportation process. ℃. After entering the jacketed hot water high-pressure enzyme dissolution tank 1, the temperature of the wine body in the tank is maintained at 40°C ± 2°C by the hot water in the jacket of the jacketed hot water high-pressure enzyme dissolver tank 1.

[0042] Step 2: Add vegetable and fruit compound enzyme powder into the jacketed hot water high-pressure enzyme dissolving tank 1 at a ratio of 10%-22% of the weight of liquor base liquor through the entrance of the automatic feeding hopper, and stir at a speed of 160-180rpm while adding ;

[0043] Step 3: Pass the sterile filtered compressed nitrogen into the jacketed hot water high-pressure enzyme dissolving tank 1, keep the pressure in the t...

Embodiment 2

[0060] Step 1: The fragrance-flavored liquor in the original liquor base liquor storage tank is input into the jacketed hot water high-pressure enzyme dissolution tank 1 through a booster pump, and the liquor is rapidly heated to 40°C through a heat exchanger during the transportation process ±2°C. After entering the jacketed hot water high-pressure enzyme dissolving tank 1, the temperature of the wine body in the tank is maintained at 40°C ± 2°C by the hot water in the jacket of the jacketed hot water high-pressure enzyme dissolver 1 jacket.

[0061] Step 2: Add vegetable and fruit compound enzyme powder into the jacketed hot water high-pressure enzyme dissolving tank 1 at a ratio of 8%-10% of the weight of the liquor base liquor through the enzyme inlet, and stir at a speed of 160-180rpm while adding;

[0062] Step 3: Pass the sterilized and filtered compressed nitrogen into the jacketed hot water high-pressure enzyme dissolution tank 1, keep the pressure in the tank at 0.15...

Embodiment 3

[0079] Step 1: The fragrance-flavored liquor in the original liquor base liquor storage tank is input into the jacketed hot water high-pressure enzyme dissolving tank 1 through a pressure pump, and the liquor is rapidly heated to 40°C± by a heat exchanger during the transportation process 2°C. After entering the jacketed hot water high-pressure enzyme dissolving tank 1, the temperature of the wine body in the tank is maintained at 40°C ± 2°C by the hot water in the jacket of the jacketed hot water high-pressure enzyme dissolver 1 jacket.

[0080] Step 2: Add vegetable and fruit compound enzyme powder into the jacketed hot water high-pressure enzyme dissolving tank 1 at a ratio of 2%-3% of the weight of liquor base liquor through the enzyme inlet, and stir at a speed of 160-180rpm while adding;

[0081] Step 3: Pass the sterilized and filtered compressed nitrogen into the jacketed hot water high-pressure enzyme dissolution tank 1, keep the pressure in the tank at 0.15-0.2Mpa, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com