Lithium ion positive electrode composite material and preparation method thereof

A composite material and lithium-ion technology, which is applied in the field of lithium-ion cathode composite materials and its preparation, can solve the problems of no obvious advantages in energy density, low discharge platform of ternary materials, cycle deterioration, etc., and achieve good product consistency and low cost , Improve the effect of low temperature discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

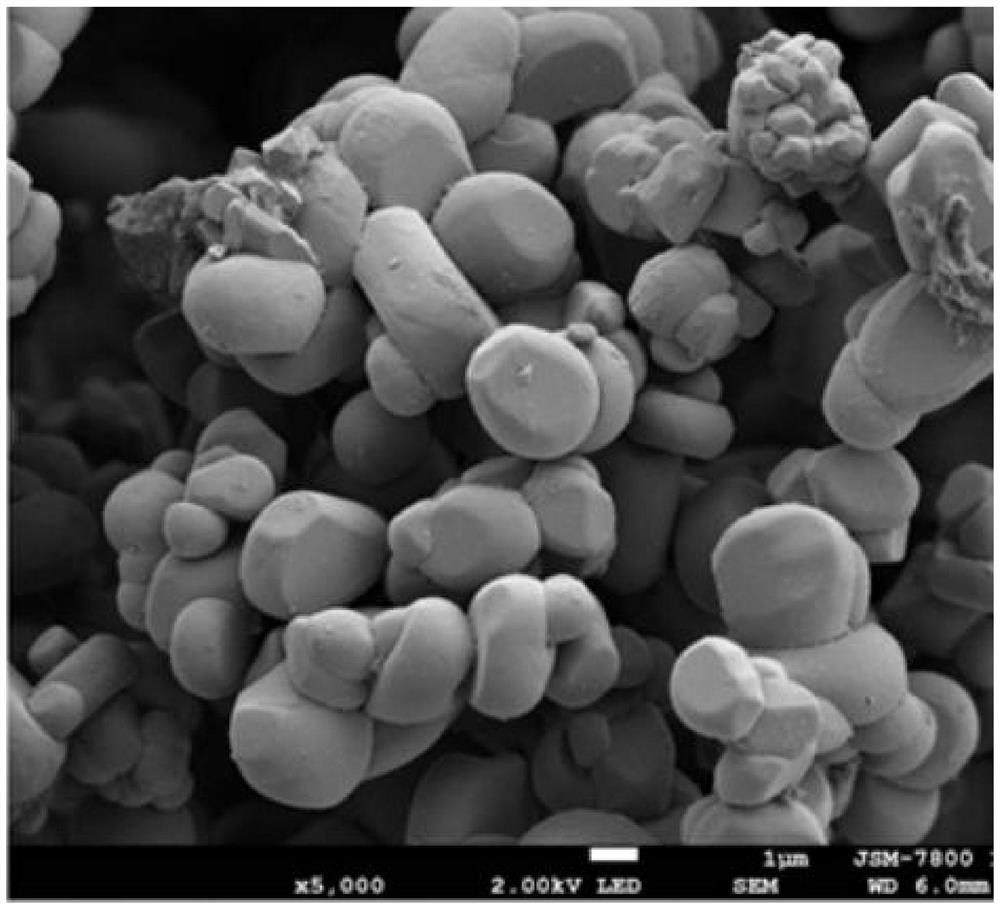

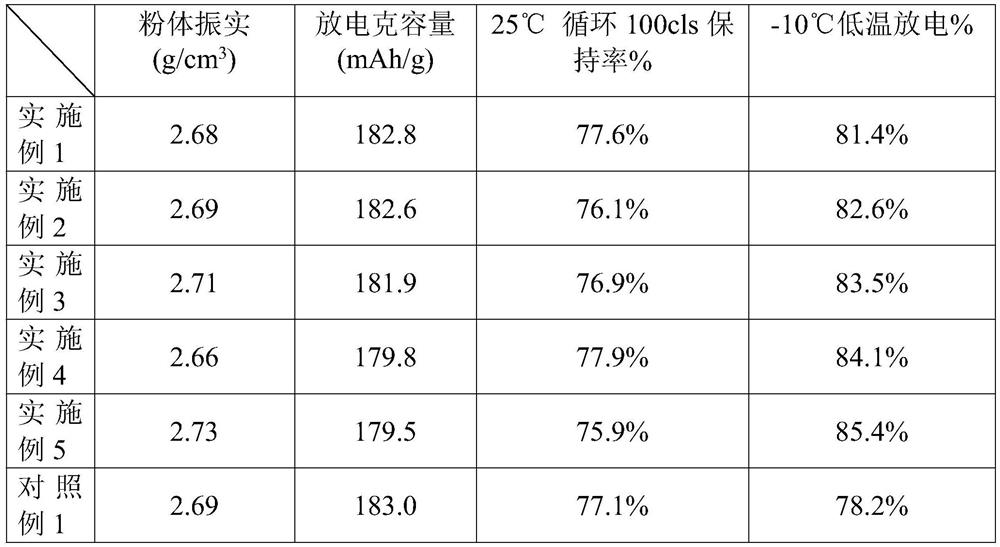

[0031] The preparation method of the lithium ion positive electrode composite material comprises: step 1, using a soluble salt of cobalt to prepare a Co solution, using carbonate as a precipitating agent, obtaining cobalt carbonate precipitation after stirring and aging, and then dissolving the obtained cobalt carbonate solid-liquid Separation, washing with deionized water, drying, and sintering at low temperature to obtain the precursor of tricobalt tetroxide; step 2, preparing the soluble salt of Ni and Mn into a metal mixed solution, using carbonate as a precipitant, and obtaining nickel manganese after stirring and aging Carbonate precipitation, and then the obtained nickel-manganese carbonate is separated from solid and liquid, washed with deionized water, dried, and sintered at low temperature to obtain the precursor of nickel-manganese oxide; step 3, the precursor prepared in step 1 and step 2 After mixing evenly with lithium salt, sintering at high temperature, and thro...

Embodiment 1

[0044] Step 1, tricobalt tetroxide (Co 3 o 4 ) Precursor preparation

[0045] Cobalt sulfate is formulated into a cobalt sulfate solution with a cobalt ion concentration of 2mol / L, and ammonium carbonate is formulated into a 0.5mol / L ammonium carbonate solution. Under the action of magnetic stirring, add ammonium carbonate with a volume ratio of 5 times to the cobalt sulfate solution Solution, the excess ammonium carbonate solution can make the cobalt ions fully precipitate, and the cobalt carbonate precipitate is obtained after stirring and aging for 2 hours, and the cobalt carbonate precipitate is filtered out with a suction filter device, washed with deionized water until the pH is 7.5, and then dried in an oven at 80°C After drying for 12 hours, the dried lithium carbonate was sintered in a muffle furnace at a low temperature of 450° C. for 10 hours to fully decompose the cobalt carbonate to prepare a precursor of tricobalt tetroxide.

[0046] Step 2, nickel manganese ox...

Embodiment 2

[0051] Different from Embodiment 1, in step 3 of this embodiment,

[0052] Weigh 8 / 3mol Co prepared in step 1 3 o 4 Precursor, weigh 4molMn prepared in step 2 0.75 Ni 0.25 O precursor, then weigh 11mol lithium carbonate (considering the volatilization of lithium salt during the sintering process, Li / Me(Me=Co+2Ni)=1.1), after the powder is mixed evenly by a ball mill, transfer to the muffle furnace for 850 ℃ high temperature sintering for 12 hours, and then natural annealing to prepare a kind of 0.8LiCoO grown by fusion of layered lithium cobalt oxide and spinel lithium nickel manganese oxide. 2 0.2LiNi 0.5 mn 1.5 o 4 Composite cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com