Hyperbranched polyamide cross-linked cyclodextrin as well as synthesis method and application thereof

A technology of hyperbranched polyamide and cross-linked cyclodextrin, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc. and other problems, to achieve excellent adsorption effect, broad application and development prospects, and the effect of large adsorption sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

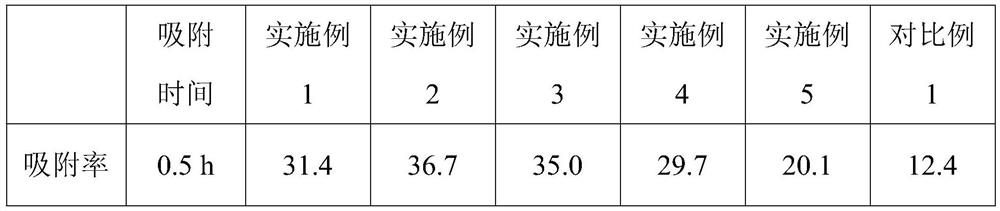

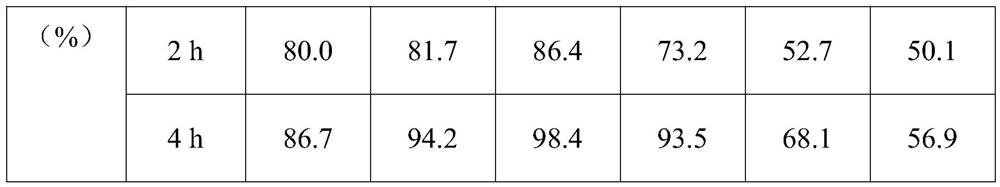

Examples

Embodiment 1

[0024] (1) Add 3.5g of N,N-methylenebisacrylamide to a mixed solvent of 20mL of distilled water and 16mL of methanol, dropwise add 3g of triethylenetetramine, and raise the temperature to 65°C in a nitrogen atmosphere to react After 24 hours of reaction, distill under reduced pressure, and wash the product with acetone and dichloromethane to prepare a hyperbranched polyamide with an amino terminal.

[0025] (2) Add 1g of cyclodextrin to 5mL of pyridine, heat to dissolve, then add 0.5g of p-toluenesulfonyl chloride dropwise, react in an ice bath for 3h, add acetone to precipitate after the reaction, filter, wash with acetone, and then add the product to In 6mL of triethylenetetramine, heat up to 60°C, react for 4 hours, cool down and add acetone to precipitate after reaction, filter, and wash with acetone to obtain triethylenetetramine-modified cyclodextrin.

[0026] (3) Add 0.5g of triethylenetetramine-modified cyclodextrin to 30mL of N,N-dimethylformamide solvent, stir well a...

Embodiment 2

[0028] (1) Add 3.5g of N,N-methylenebisacrylamide to a mixed solvent of 20mL distilled water and 20mL methanol, dropwise add 3.5g of triethylenetetramine, and raise the temperature to 65°C in a nitrogen atmosphere, After reacting for 36 hours, distilling under reduced pressure after the reaction, washing the product with acetone and dichloromethane to prepare a hyperbranched polyamide with amino terminal.

[0029] (2) Add 1g of cyclodextrin to 8mL of pyridine, heat to dissolve, then add 0.6g of p-toluenesulfonyl chloride dropwise, react in ice bath for 4h, add acetone to precipitate after the reaction, filter, wash with acetone, and then add the product to In 10mL of triethylenetetramine, heat up to 75°C, react for 10h, cool and add acetone to precipitate after reaction, filter, wash with acetone, and obtain triethylenetetramine-modified cyclodextrin.

[0030] (3) Add 0.8g of triethylenetetramine-modified cyclodextrin to 40mL of N,N-dimethylacetamide solvent, stir well and add...

Embodiment 3

[0032] (1) Add 3.5g of N,N-methylenebisacrylamide to a mixed solvent of 20mL distilled water and 30mL methanol, dropwise add 4.2g of triethylenetetramine, and raise the temperature to 80°C in a nitrogen atmosphere, After reacting for 30 h, distilling under reduced pressure after the reaction, washing the product with acetone and dichloromethane to prepare a hyperbranched polyamide with an amino terminal.

[0033] (2) Add 1g of cyclodextrin to 8mL of pyridine, heat to dissolve, then add 0.7g of p-toluenesulfonyl chloride dropwise, react in an ice bath for 5h, add acetone to precipitate after the reaction, filter, wash with acetone, and then add the product to In 12mL of triethylenetetramine, heat up to 75°C, react for 8h, cool down and add acetone to precipitate after reaction, filter, wash with acetone, and obtain triethylenetetramine-modified cyclodextrin.

[0034] (3) Add 1g of triethylenetetramine-modified cyclodextrin to 50mL of N-methylpyrrolidone solvent, stir well and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com