Process for manufacturing bamboo shaving board with flat surface and oriented structure and paving machine

A flat surface, particle board technology, applied in the direction of wood veneer joining, manufacturing tools, flat products, etc., can solve the inconvenient adjustment of the slice size, increase the use effect of the first particle board and the second particle board, and inconvenient simultaneous screening and drying and other problems, to achieve the effect of convenient production and cutting work, high mechanical properties, and convenient positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

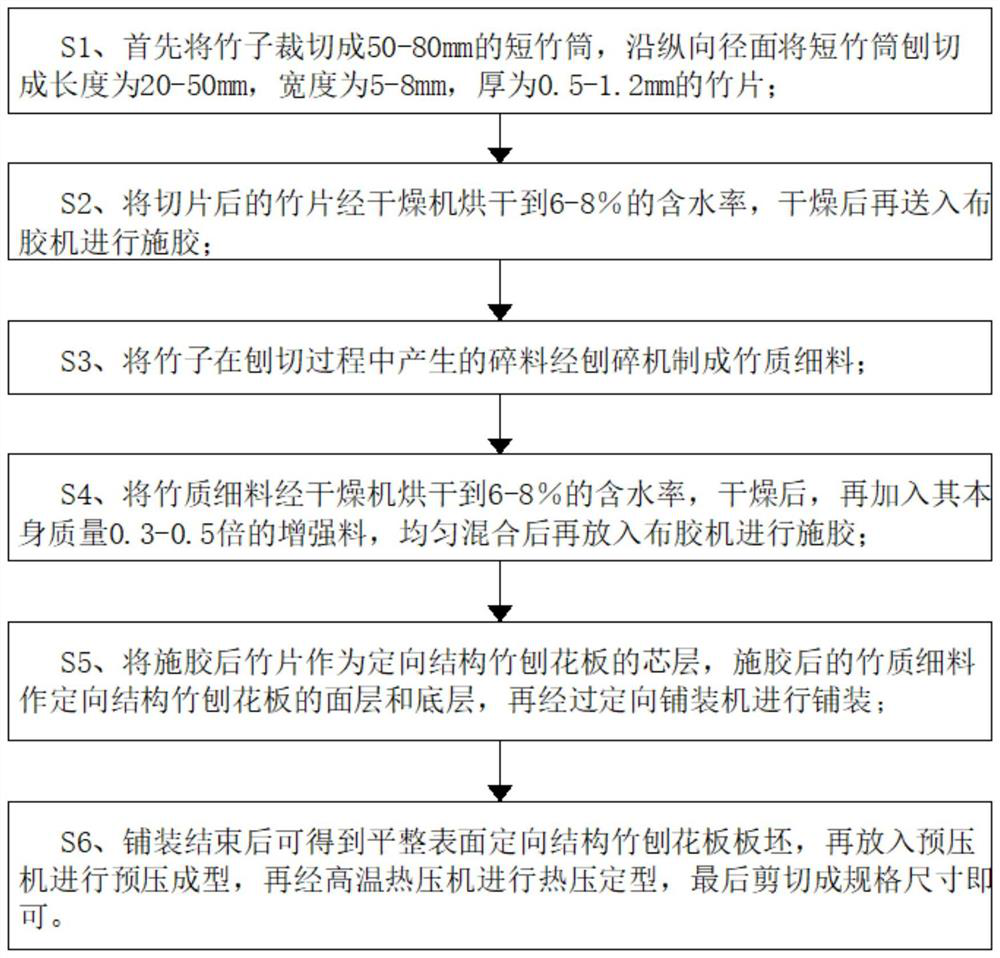

[0054] A kind of technique of making flat surface oriented structure bamboo particle board, as figure 1 shown, including the following steps:

[0055] S1, at first bamboo is cut into the short bamboo tube of 50mm, and the short bamboo tube is sliced into length along the longitudinal diameter surface and is 20-50mm, and width is 5-8mm, and the bamboo chip that is thick is 0.5-1.2mm;

[0056] S2, drying the sliced bamboo slices to a moisture content of 6% through a drier, and then sending them into the gluing machine for sizing after drying;

[0057] S3, making the scraps produced by the bamboo in the planing process into bamboo fines through a shredder;

[0058] S4, drying the bamboo fine material to a moisture content of 6% through a drier, after drying, add a reinforcing material of 0.4 times its own quality, and put it into a gluing machine for sizing after evenly mixing;

[0059] S5, the bamboo chips after gluing are used as the core layer of the oriented structure b...

Embodiment 2

[0063] A kind of technique of making flat surface oriented structure bamboo particle board, as figure 1 shown, including the following steps:

[0064] S1, first cut the bamboo into 70mm short bamboo tubes, slice the short bamboo tubes into lengths of 20-50mm, width 5-8mm, and thick bamboo slices of 0.5-1.2mm along the longitudinal diameter surface;

[0065] S2, drying the sliced bamboo slices to a moisture content of 7% through a drier, and then sending them to a glue distribution machine for sizing after drying;

[0066] S3, making the scraps produced by the bamboo in the planing process into bamboo fines through a shredder;

[0067] S4, drying the bamboo fine material to a moisture content of 7% through a drier, after drying, add a reinforcing material of 0.4 times its own quality, and put it into a gluing machine for sizing after evenly mixing;

[0068] S5, the bamboo chips after gluing are used as the core layer of the oriented structure bamboo particle board, and the ...

Embodiment 3

[0072] A kind of technique of making flat surface oriented structure bamboo particle board, as figure 1 shown, including the following steps:

[0073] S1, first cut bamboo into short bamboo tubes of 80 mm, slice the short bamboo tubes into lengths of 20-50 mm, width of 5-8 mm, and bamboo slices of 0.5-1.2 mm thick along the longitudinal diameter surface;

[0074] S2, drying the sliced bamboo slices to a moisture content of 8% through a drier, and then sending them into a glue distributing machine for sizing after drying;

[0075] S3, making the scraps produced by the bamboo in the planing process into bamboo fines through a shredder;

[0076] S4, drying the bamboo fine material to a moisture content of 8% through a drier, after drying, add a reinforcing material of 0.5 times its own quality, and put it into a gluing machine for sizing after evenly mixing;

[0077] S5, the bamboo chips after gluing are used as the core layer of the oriented structure bamboo particle board, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com