Bamboo-like carbon nanotube composite material based on wood carbonized porous structure and preparation method of bamboo-like carbon nanotube composite material

A technology of porous structure and carbon nanotubes, applied in the direction of carbon nanotubes, carbon preparation/purification, carbon compounds, etc., can solve the problems of easy aggregation of active substances, complicated process, uncontrollable and other problems, and achieve simple preparation method and process Short, in situ growth-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

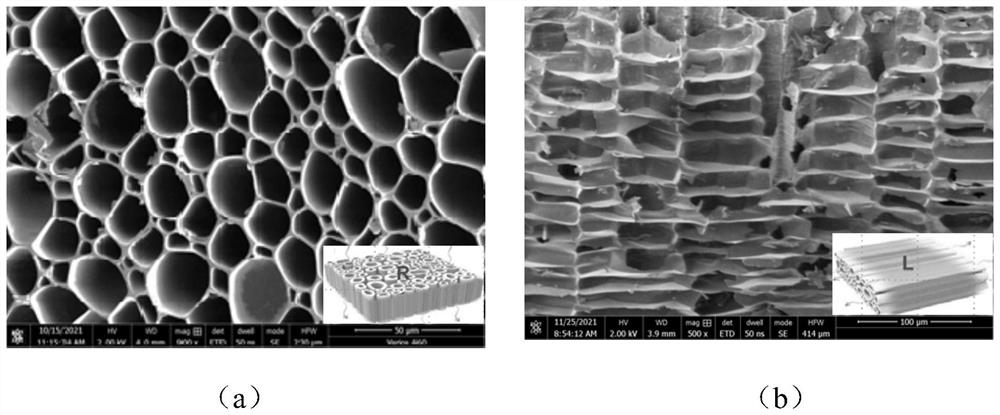

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings; the present invention discloses a method for bamboo-shaped carbon nanotube composite material based on woody carbonized porous structure. The preparation method comprises the following steps:

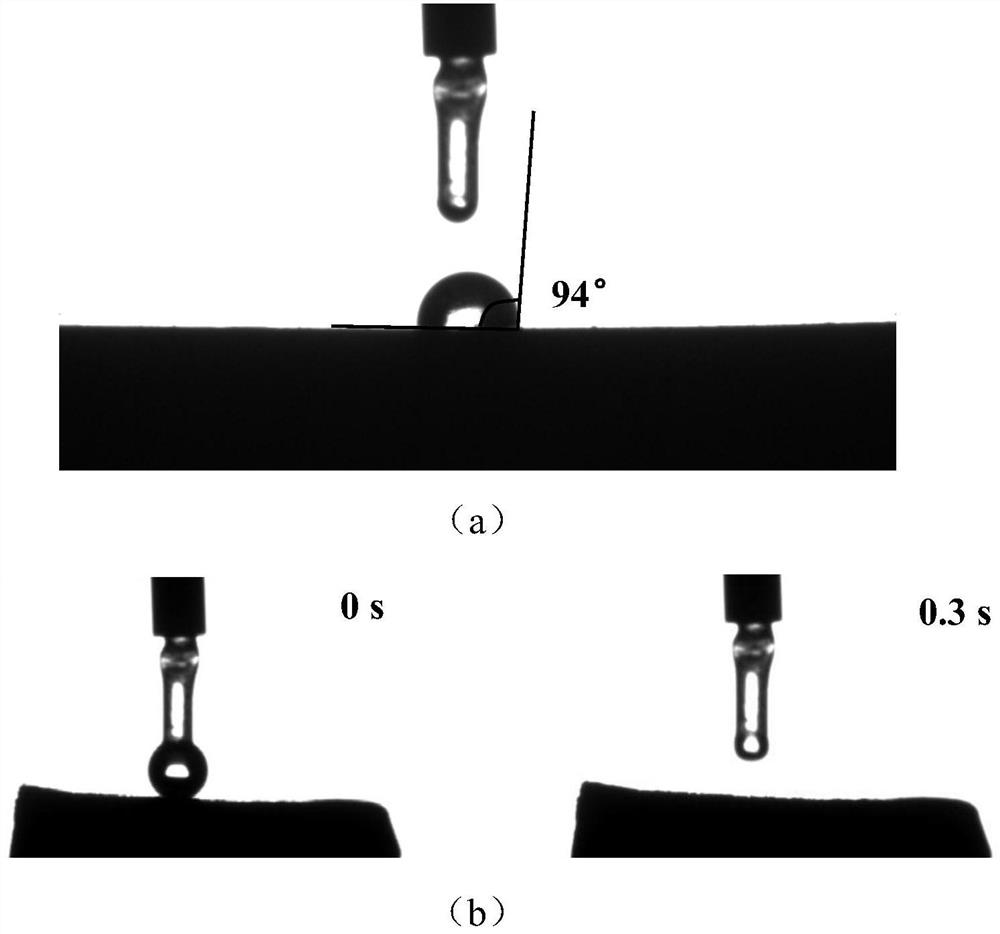

[0043] Step 1, take a wooden material with a size of 3mm*30mm*30mm and place it in a plasma cleaning machine, and set parameters for hydrophilic treatment. The size can be adjusted arbitrarily. The specific process of oxygen plasma treatment is as follows: put the balsa wood in the plasma cleaning machine, set the vacuum degree in the cavity to 10-100Pa, the power of the radio frequency power supply to 100-300W, the cleaning time to 400-800s, and the flow rate of the oxygen gas path to be 50-200mL / min, if the air flow rate is too large, it will cause too many defects in the wood material, and if the air flow rate is too low, it will reduce the hydrophilicity of the wood...

Embodiment 1

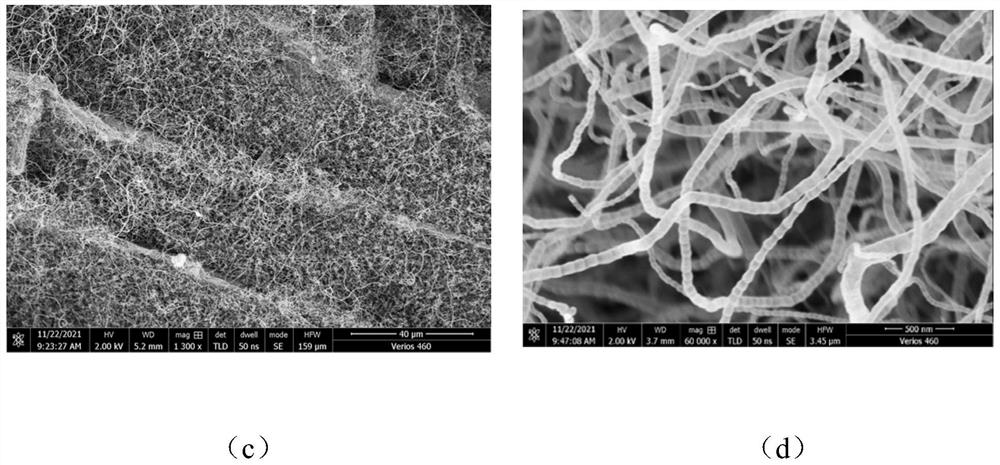

[0050] Take a wooden material with a size of 3mm*30mm*30mm and place it in the plasma cleaning machine, set the vacuum degree in the cavity to 10Pa, the power of the RF power supply to 150W, the cleaning time to 400s, the flow rate of the oxygen gas path to 50ml / min, and oxygen plasma cleaning treatment After completion, take it out for use; weigh 0.25g polyvinylpyrrolidone K30, 0.25g Fe(NO 3 ) 3 9H 2 O is placed in a beaker and 10mL of ethylene glycol is added, and a light yellow solution is obtained after magnetic stirring for 10 minutes. Then, the wooden material is completely soaked in the mixed solution and placed in a vacuum drying oven. The vacuum impregnation temperature is 100°C, and the vacuum impregnation time is After 24 hours, the hydrophilic woody material attached with the precursor of the reaction product was taken out from the solution, and vacuum-dried at a drying temperature of 80° C. for 12 hours. Take out the wooden material attached with the precursor o...

Embodiment 2

[0059] Take a wooden material with a size of 3mm*30mm*30mm and place it in the plasma cleaning machine, set the vacuum degree in the cavity to 10Pa, the power of the RF power supply to 150W, the cleaning time to 400s, the flow rate of the oxygen gas path to 50ml / min, and the oxygen plasma cleaning is completed After that, take it out for use; weigh 0.25g polyvinylpyrrolidone K30, 0.25g Co(NO 3 ) 3 ·6H 2 O was placed in a beaker and 10mL of ethylene glycol was added, and a light pink solution was obtained after magnetic stirring for 10 minutes. Then, the wooden support was completely immersed in the mixed solution, placed in a vacuum drying oven, and the vacuum impregnation temperature was 100°C. The time is 24 hours, and the woody material is taken out from the solution, and vacuum-dried, the drying temperature is 80° C., and the drying time is 12 hours. Take out the dry woody material with the precursor of the reaction product attached and put it into a graphite furnace, we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com