Water-swellable single-component prepolymer as well as preparation method and application thereof

A water-swelling, one-component technology, applied in the field of plastic materials, can solve problems such as insufficient adhesion, and achieve the effects of preventing ultraviolet and acid-base damage, uniformly dispersing force, and preventing diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

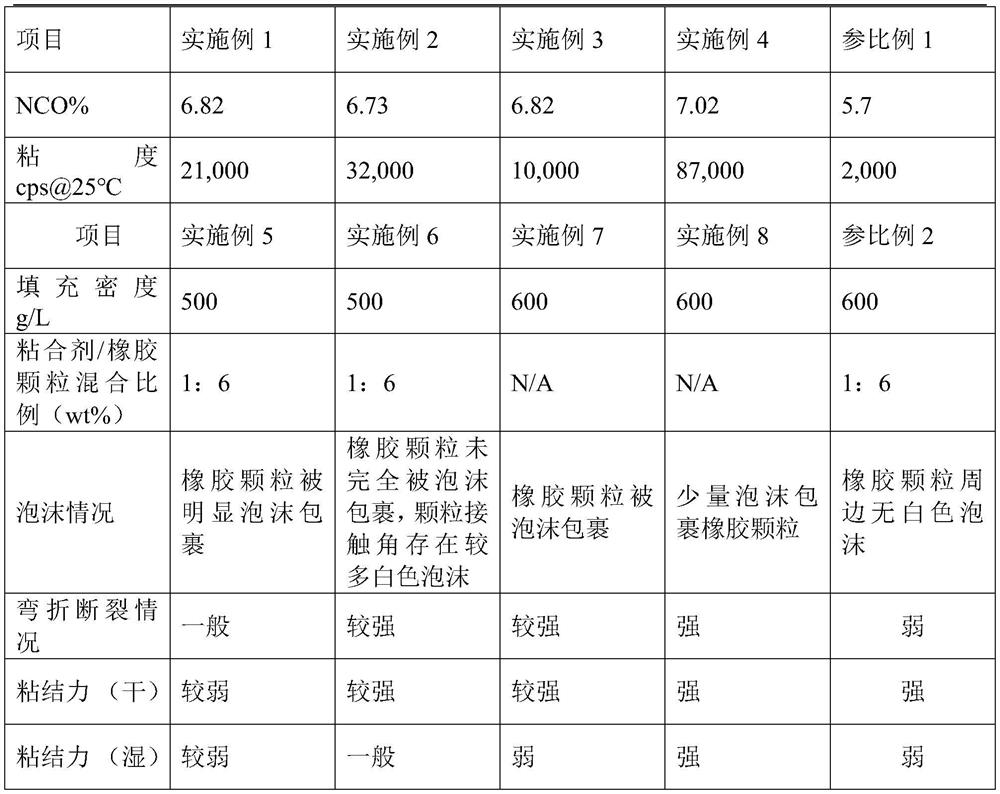

Examples

Embodiment 1

[0022] A water-swellable one-component prepolymer comprises the following synthesis method:

[0023] Step 1: Dehydrate the two-functional polyethylene glycol C at 110°C for 4-8 hours, and then keep it in a constant temperature drying container at 40°C;

[0024] Step 2: Add 451.7 parts of isomers of methylene diphenyl diisocyanate into the reaction kettle, raise the temperature to about 60-70°C, and put 548.3g of polyethylene glycol C in step 1 into the reaction kettle in batches , control the reaction temperature not to exceed 75°C, and react for 2-4 hours. At this time, the theoretical NCO of the reactant is 7.7, and the actual measured NCO=7.58, and the appearance is light yellow viscous liquid;

[0025] Step 3: Add 100 parts of propylene glycol methyl ether acetate into the reactor and stir the reactant obtained in Step 2 evenly at 40° C., and the obtained product is the reactant of Example 1.

[0026] In this embodiment, polyethylene glycol C is an adduct of ethylene oxid...

Embodiment 2

[0028] A water-swellable one-component prepolymer comprises the following synthesis method:

[0029] Step 1: Mix 109 parts of polyether polyol A and 530 parts of polyether polyol B evenly, dehydrate at 110°C for 4-8 hours, then cool and place in a constant temperature drying container;

[0030] Step 2: Add 201 parts of isomers of methylene diphenyl diisocyanate into the reactor, raise the temperature to about 60-70°C, put the polyether polyol mixture in step 1 into the reactor in batches, Control the reaction temperature not to exceed 75°C, and react for 2-4 hours. At this time, the theoretical NCO of the reactant is 5%, and the actual measured NCO=5.12. The appearance is a colorless to light yellow liquid, and the obtained product is the reactant of Example 2;

[0031] Step 3: Add 100 parts of the product of Step 2, 10 parts of liquefied methylene diphenyl diisocyanate, and 10 parts of propylene glycol methyl ether acetate into the reaction kettle and stir evenly at 40°C. The...

Embodiment 3

[0034] A water-swellable one-component prepolymer comprises the following synthesis method:

[0035] Step 1: Dehydrate 409 parts of polyether polyol D under vacuum 5 Torr below 100°C for 4-8 hours until the water content of the system reaches below 200ppm, and leave it for 24 hours to cool to room temperature;

[0036] Step 2: Add 102 parts of TDI-80 into the reactor and stir evenly, raise the temperature to 65-60°C, add the result of step 1 into the reactor, and react for 4-8 hours. The theoretical NCO of the obtained reactant is 6.9%. The NCO% is 6.83, the free TDI is 1.7%, the appearance is light yellow liquid, and the obtained product is the reactant of Example 3.

[0037] In this embodiment, polyether polyol D is a copolymerized adduct of propylene oxide and ethylene oxide starting from glycerin, propylene oxide accounts for 25% of the total substance content, and the molecular weight is about 4000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com