Polyether polyol as well as preparation method and application thereof

A technology of polyether polyol and diol, applied in the field of polyether polyol, can solve the problems of affecting product yield and post-processing difficulty, restricting applicability and product performance, affecting product quality, etc. Adjustable, good compatibility, good heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1) Pressurized etherification reaction:

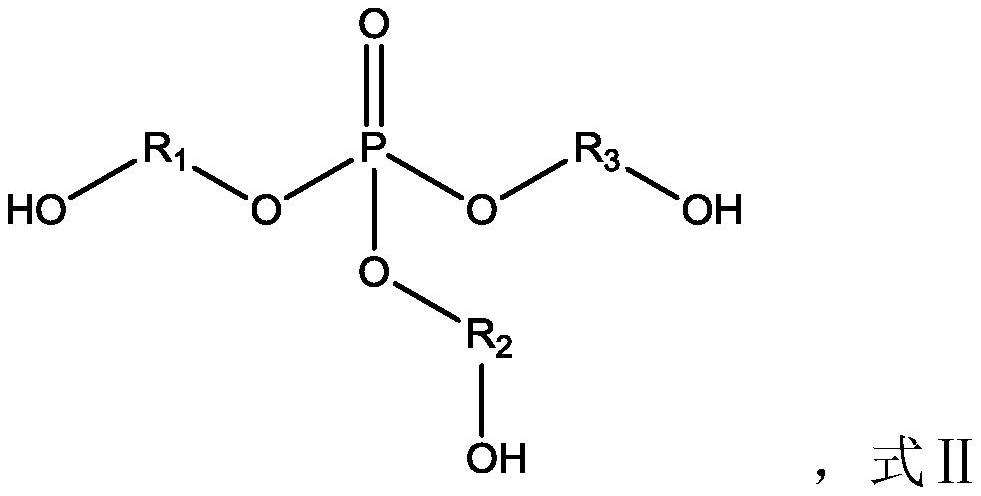

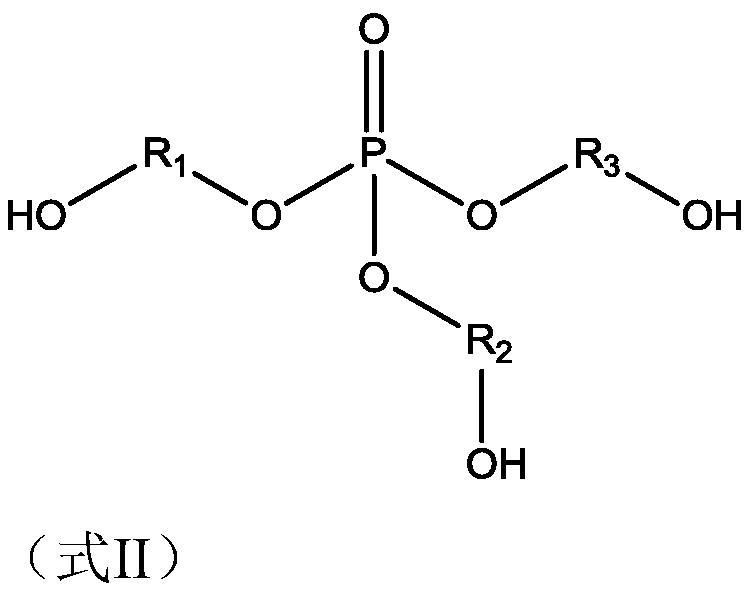

[0050] 1379.3 g (13 mol) of diethylene glycol, 13.8 g (1 wt % of diethylene glycol) with the structure of the following formula II catalyst were added to the tank reactor at 60 ° C, and nitrogen was charged to 0.2 MPa. After the temperature was raised to 160°C at a rate of / min, the pressure was adjusted to 2.5MPa, and the reaction was continued for 5h at this temperature and pressure.

[0051]

[0052]

[0053] 2) Decompression dehydration:

[0054] Cool the reaction product of step 1) to 90°C, then reduce the pressure to 1kPa within 1h, and maintain this pressure for 4h to remove small molecule by-product water and unreacted monomeric diol;

[0055] 3) Pressurized etherification reaction:

[0056] The product obtained in the step 2) was heated to 210° C. under normal pressure, and 0.14 g of isopropyl titanate (100 ppm of diethylene glycol) was added for further reaction for 2 h.

[0057] 4) Decatalyst treatment:

[0...

Embodiment 2

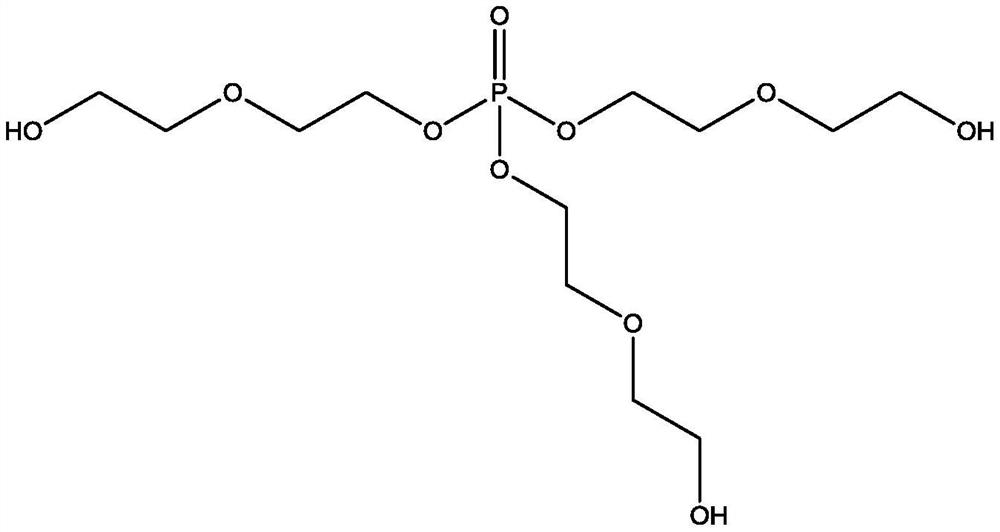

[0063] 1) Pressurized etherification reaction:

[0064] 1354.0 g (13 mol) of 1,5-pentanediol and 1.4 g (0.1 wt % of 1,5-pentanediol) of the catalyst with the following structure were added to the tank reactor at 80°C, and nitrogen was charged to 0.25 MPa, the temperature was raised to 140°C at a rate of 1°C / min, and the pressure was adjusted to 2.9MPa, and the reaction was continued for 8h at this temperature and pressure.

[0065]

[0066] 2) Decompression dehydration:

[0067] Cool the reaction product of step 1) to 80°C, then reduce the pressure to 0.2kPa within 1h, and maintain this pressure for 3h to remove small molecule by-product water and unreacted monomeric diol;

[0068] 3) Pressurized etherification reaction:

[0069] The product obtained in the step 2) was heated to 200° C. under normal pressure, and 0.04 g of isopropyl titanate (29 ppm of 1,5-pentanediol) was added to further react for 4 h.

[0070] 4) Decatalyst treatment:

[0071] The product obtained in...

Embodiment 3

[0076] 1) Pressurized etherification reaction:

[0077] 1900.6 g (13 mol) of 1,8-octanediol and 0.6 g (0.03 wt % of 1,8-octanediol) of the catalyst with the following structure were added to the tank reactor at 20°C, and nitrogen was charged to 0.3 MPa, the temperature was raised to 120°C at a rate of 3°C / min, and the pressure was adjusted to 2.0 MPa, and the reaction was continued for 7 hours at this temperature and pressure.

[0078]

[0079] 2) Decompression dehydration:

[0080] Cool the reaction product of step 1) to 70°C, then reduce the pressure to 0.02kPa within 1h, and maintain this pressure for 2h to remove small molecule by-product water and unreacted monomeric diol;

[0081] 3) Pressurized etherification reaction:

[0082] The product obtained in the step 2) was heated to 180° C. under normal pressure, and 0.10 g of n-butyl titanate (55 ppm of 1,8-octanediol) was added for further reaction for 4 h.

[0083] 4) Decatalyst treatment:

[0084] The product obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com