High-efficiency high-temperature-resistant proton conduction material and preparation method thereof

A technology of proton conduction and energy resistance, which is applied in the field of high-efficiency, high-temperature-resistant proton conduction materials and their preparation, and can solve the problems of expensive Nafion membranes, limited thermal stability, and loss of functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

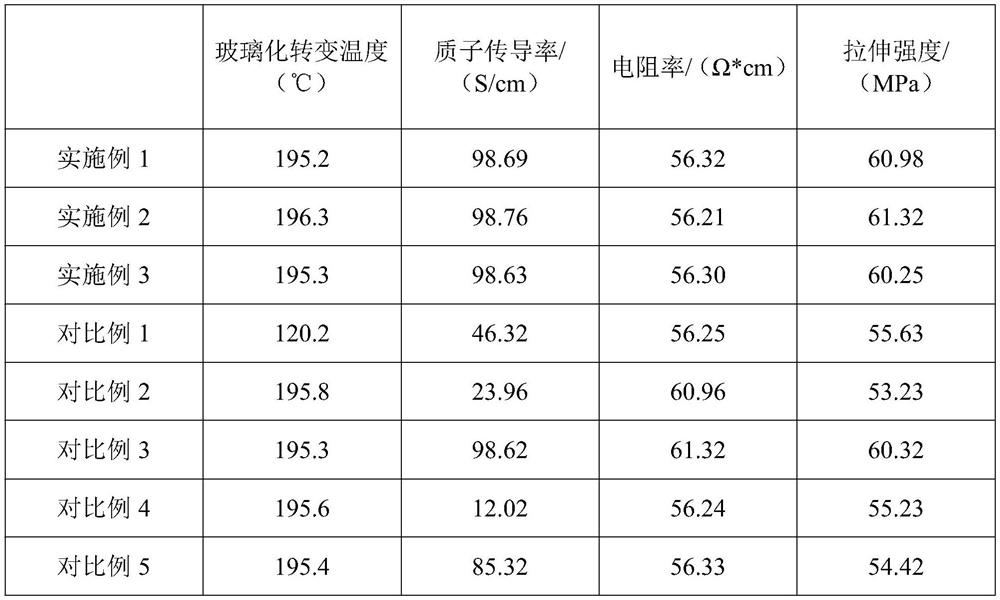

Examples

Embodiment 1

[0030] A method for preparing a high-efficiency high-temperature-resistant proton-conducting material, the method for preparing a high-efficiency high-temperature-resistant proton-conducting material includes the following preparation steps:

[0031](1) At 24°C, mix (trityloxy)trichlorosilane and malonic acid at a mass ratio of 1:2.5, stir at 1200r / min for 1h, then stand for 24h, and then react at 1°C / min Raise the temperature to 108°C, rectify at 0.08MPa for 22h, and prepare trimalonyl (trityloxy)silane; at 6°C and nitrogen protection, 4,5-diamino-o-chloro-sulfurized benzyl Acyl chloride, aluminum trichloride, and benzene were mixed according to the mass ratio of 1:1.4:17, and stirred and refluxed at 600r / min for 40min to prepare a 4,5-diamino-o-chlorosulfurized benzoyl chloride solution; under nitrogen protection, the three Mix malonyl (trityloxy) silane and benzene at a mass ratio of 1:8, put it in a 98°C oil bath, stir and reflux at 600r / min for 40min, then cool down to 6°...

Embodiment 2

[0034] A method for preparing a high-efficiency high-temperature-resistant proton-conducting material, the method for preparing a high-efficiency high-temperature-resistant proton-conducting material includes the following preparation steps:

[0035] (1) At 25°C, mix (trityloxy)trichlorosilane and malonic acid at a mass ratio of 1:3, stir at 1300r / min for 1.5h, then stand for 25h, and then react at 2°C / min Min was raised to 110°C, and rectified at 0.085MPa for 24 hours to prepare trimalonyl (tritylmethoxy)silane; at 6.5°C and under the protection of nitrogen, 4,5-diamino-o-chlorosulfurized benzene Formyl chloride, aluminum trichloride, and benzene were mixed according to the mass ratio of 1:1.6:17.5, stirred and refluxed at 700r / min for 50min, and 4,5-diamino-o-chlorosulfurized benzoyl chloride solution was prepared; under nitrogen protection, the Mix trimalonyl (trityloxy) silane and benzene at a mass ratio of 1:10, put it in an oil bath at 100°C, stir and reflux at 700r / min ...

Embodiment 3

[0038] A method for preparing a high-efficiency high-temperature-resistant proton-conducting material, the method for preparing a high-efficiency high-temperature-resistant proton-conducting material includes the following preparation steps:

[0039] (1) At 26°C, mix (trityloxy)trichlorosilane and malonic acid at a mass ratio of 1:3.5, stir at 1400r / min for 2h, then stand for 26h, and then react at 3°C / min Raise the temperature to 112°C, rectify at 0.09MPa for 26h, and prepare trimalonyl (tritylmethoxy)silane; at 7°C and under the protection of nitrogen, 4,5-diamino-o-chlorinated benzylsulfide Acyl chloride, aluminum trichloride, and benzene were mixed according to the mass ratio of 1:1.8:18, and stirred and refluxed at 800r / min for 60min to prepare a 4,5-diamino-o-chlorosulfurized benzoyl chloride solution; under nitrogen protection, the three Mix malonyl (trityloxy) silane and benzene at a mass ratio of 1:12, put it in an oil bath at 102°C, stir and reflux at 800r / min for 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| illuminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com