Method for recovering micro-nano copper powder from waste printed circuit board

A technology of printed circuit board and nano copper powder is applied in the field of electronic waste recycling, which can solve the problems of low copper recovery efficiency and complex production process, and achieve the effects of pollution-free, low environmental pollution and wide applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

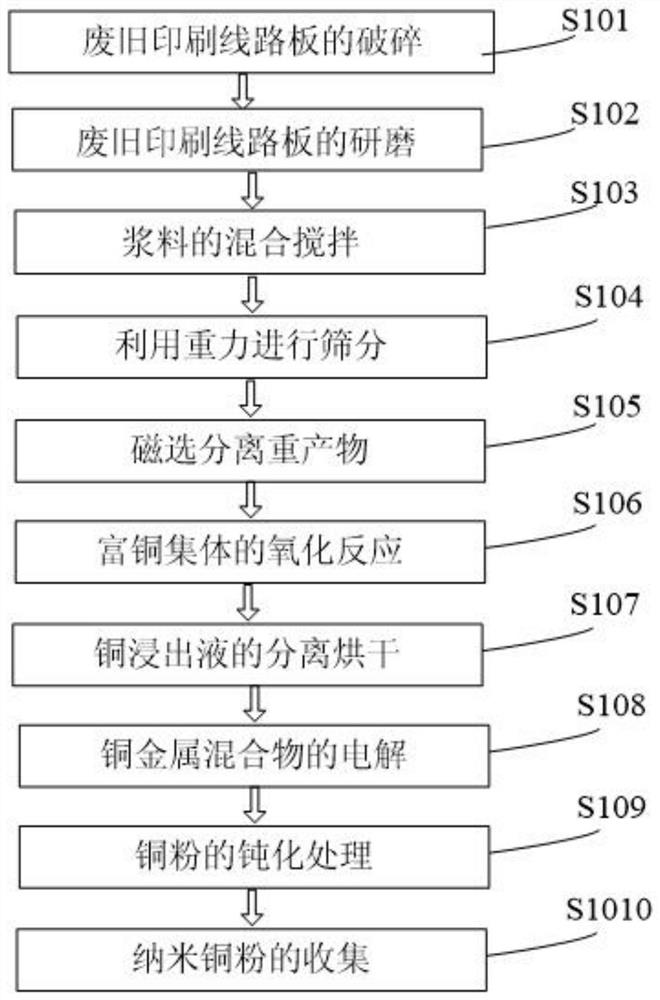

[0071] The invention discloses a method for recovering micronano copper powder from waste printed circuit boards. The specific steps are as follows:

[0072] Step 1: Crushing of waste printed circuit boards; coarsely crushing the waste printed circuit boards with a crusher into pieces smaller than 15cm×15cm, and then crushing them with a strong plastic crusher and a sealed sample preparation grinder to obtain Waste printed circuit board pulverized material, the particle size of the waste printed circuit board pulverized material is ≤30 mesh;

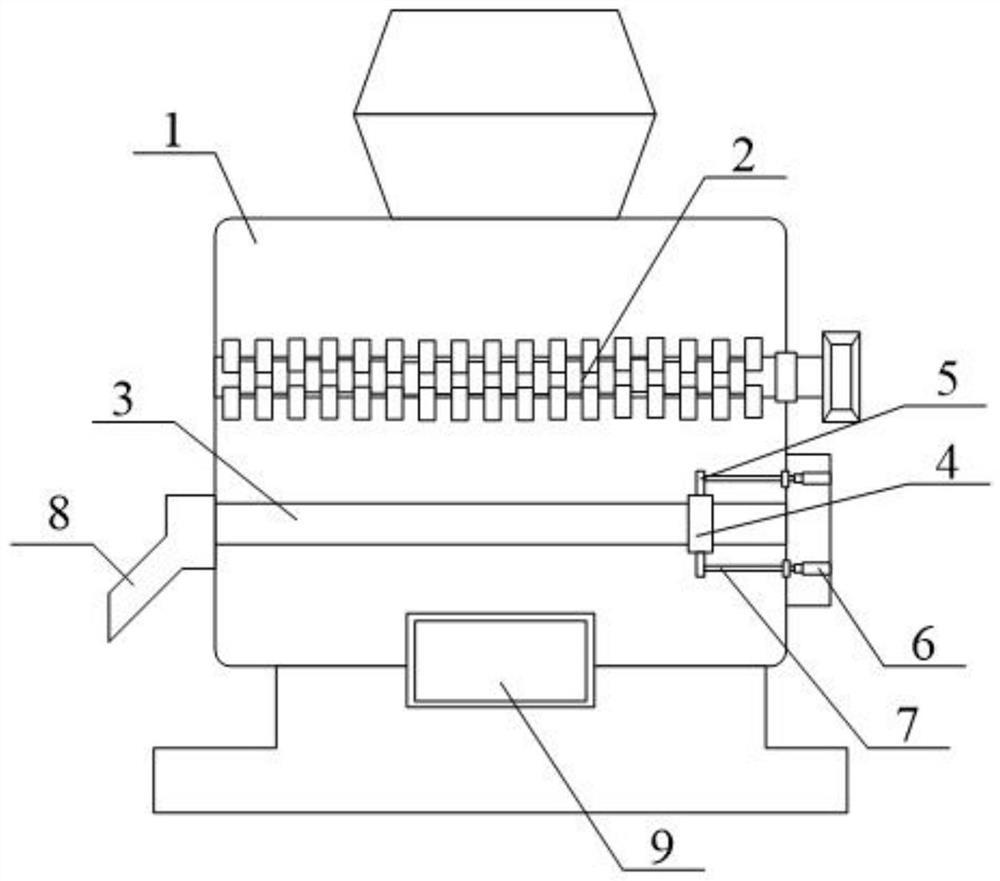

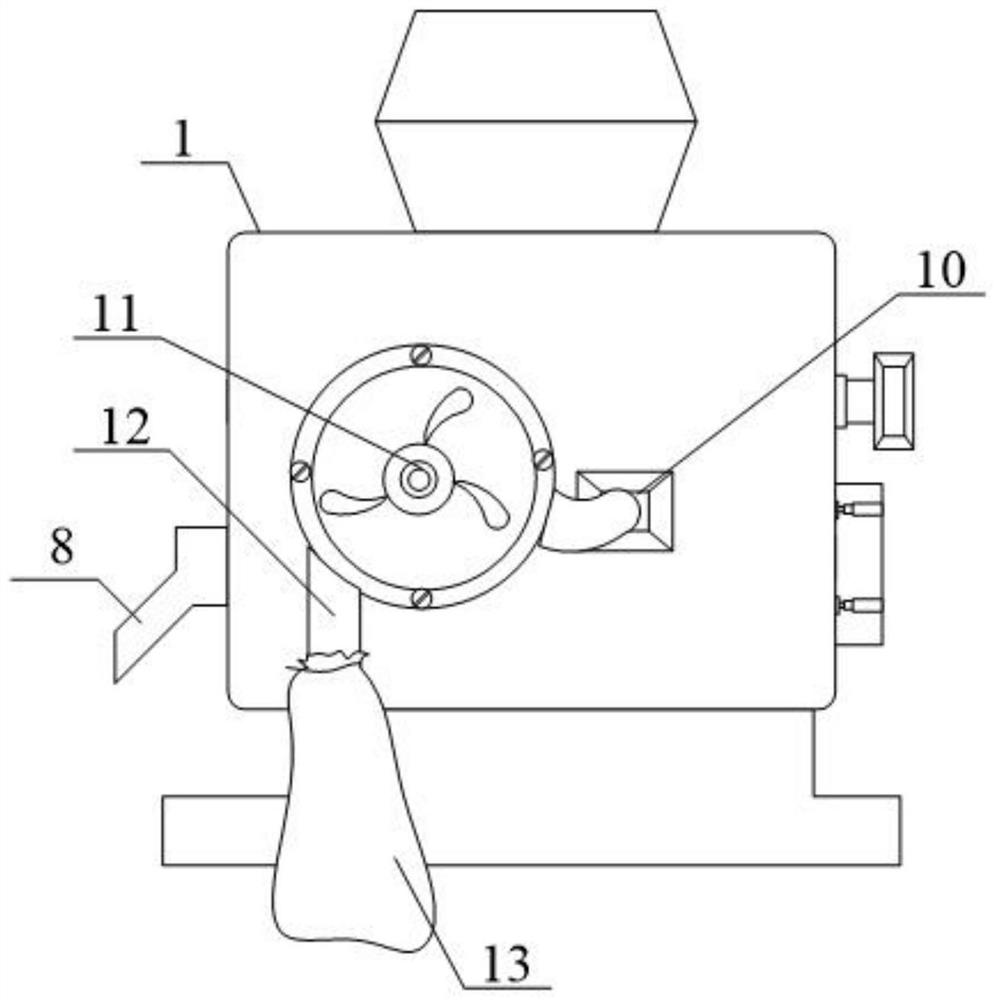

[0073] Step 2: Grinding of waste printed circuit boards; the small pieces of material obtained by the preliminary shearing in step 1 are sent to the cutting grinder, and in the cutting grinder, the blades rotating at high speed further crush the small pieces of material to obtain a particle size smaller than 10mm fine-grained material;

[0074] Step 3: mixing and stirring the slurry; sending the fine-grained material in step 2 and an ap...

Embodiment 2

[0083] The invention discloses a method for recovering micronano copper powder from waste printed circuit boards. The specific steps are as follows:

[0084] Step 1: Crushing of waste printed circuit boards; coarsely crushing the waste printed circuit boards with a crusher into pieces smaller than 15cm×15cm, and then crushing them with a strong plastic crusher and a sealed sample preparation grinder to obtain Waste printed circuit board pulverized material, the particle size of the waste printed circuit board pulverized material is ≤30 mesh;

[0085] Step 2: Grinding of waste printed circuit boards; the small pieces of material obtained by the preliminary shearing in step 1 are sent to the cutting grinder, and in the cutting grinder, the blades rotating at high speed further crush the small pieces of material to obtain a particle size smaller than 10mm fine-grained material;

[0086] Step 3: mixing and stirring the slurry; sending the fine-grained material in step 2 and an ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com