SiC particle reinforced aluminum-based composite bar with size gradient and preparation method of SiC particle reinforced aluminum-based composite bar

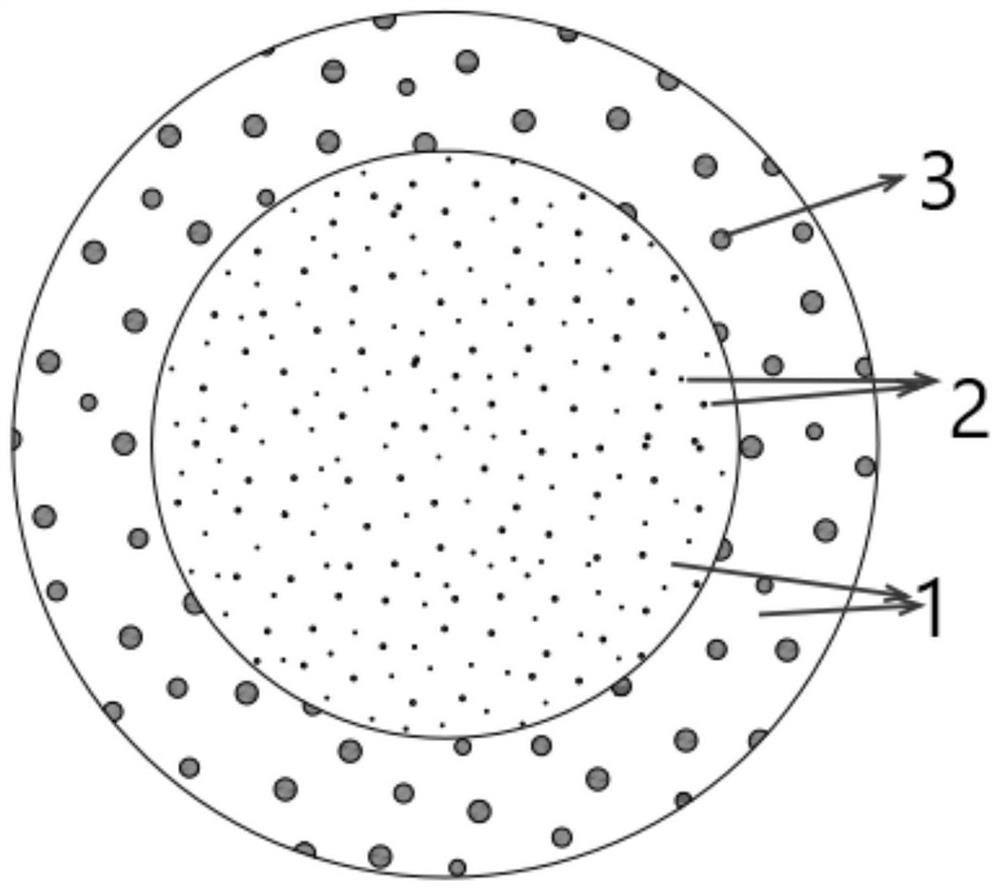

A particle-reinforced aluminum and composite rod technology, which is used in manufacturing tools, heat treatment equipment, casting and molding equipment, etc., can solve the problems of reduced plasticity of the second layer material, inability to make large products, and poor secondary processing formability. The effect of improving wear resistance, not easy to agglomerate and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The above-mentioned method for preparing the SiC particle-reinforced aluminum-based composite rod with a size gradient specifically includes the following steps:

[0033] (1): Firstly, industrial pure aluminum powder (99.7wt%), industrial pure silicon powder (99.9wt%) and graphite powder are configured into raw materials according to a certain ratio, which are fully mixed and put into a planetary ball mill for ball milling, The ball milling time is 1h±10min, and the speed is 350~400r / min. After ball milling, sinter in an argon protective atmosphere furnace, the sintering temperature is 600-800°C, and the time is 2h±30min. The sintered sample is hot-extruded into a rod with a diameter of 5-20 mm at a temperature of 300-400 ° C, and the protection of an inert gas is required during the process.

[0034] (2): Grinding the prepared bar to remove the oxide layer on the outer surface and then putting it into a mold groove with a cylindrical cavity.

[0035] (3): Industrial pu...

Embodiment 1

[0040] (1): Firstly, industrial pure aluminum powder, industrial pure silicon powder, and graphite powder are configured as raw materials according to a certain ratio, and they are fully mixed and ball milled for 1 hour at a speed of 350r / min. After the ball milling, it was sintered in an argon protective atmosphere furnace at a sintering temperature of 650°C for 2 hours. The sintered sample was hot-extruded into a rod with a diameter of 15 mm at a temperature of 300 ° C, and the extrusion ratio was 6;

[0041] (2): Grinding the prepared bar to remove the oxide layer on the outer surface and then putting it into the cylindrical groove at the bottom of the mold, the inner diameter of the mold is 60mm, the depth is 300mm, the groove diameter is 15mm, and the depth is 10mm;

[0042] (3): Melt industrial pure aluminum ingots at a temperature of 680°C to form molten aluminum, and add preheated micron-sized SiC particles into the aluminum solution for mechanical stirring. The stirr...

Embodiment 2

[0048] (1): Firstly, industrial pure aluminum powder, industrial pure silicon powder, and graphite powder are configured as raw materials according to a certain ratio, and they are fully mixed and ball milled for 1 hour at a speed of 350r / min. After ball milling, sinter in an argon protective atmosphere furnace at a sintering temperature of 600°C for 2 hours. The sintered sample was hot-extruded into a rod with a diameter of 8 mm at a temperature of 350 ° C, and the extrusion ratio was 6;

[0049] (2): Grinding the prepared bar to remove the oxide layer on the outer surface and then putting it into the cylindrical groove at the bottom of the mold. The inner diameter of the mold is 25mm, the depth is 280mm, the groove diameter is 8mm, and the depth is 10mm;

[0050] (3): Industrial pure aluminum ingots are melted at a temperature of 690° C. into molten aluminum, and preheated micron-sized SiC particles are added to the molten aluminum for mechanical stirring. The stirring temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com