Hot carrier bidirectional separation type p-i-n type two-dimensional heterojunction, preparation method and device

A p-i-n, two-dimensional heterojunction technology, applied in the field of hot carrier bidirectional separation type p-i-n type two-dimensional heterojunction and preparation, can solve the problem that the interaction between light and matter is not strong enough, and the photocurrent of photogenerated carriers is reduced. , the interface is not clean enough, etc., to achieve the effect of easy to achieve large-scale sample preparation, solve the bubble generation, and facilitate device integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

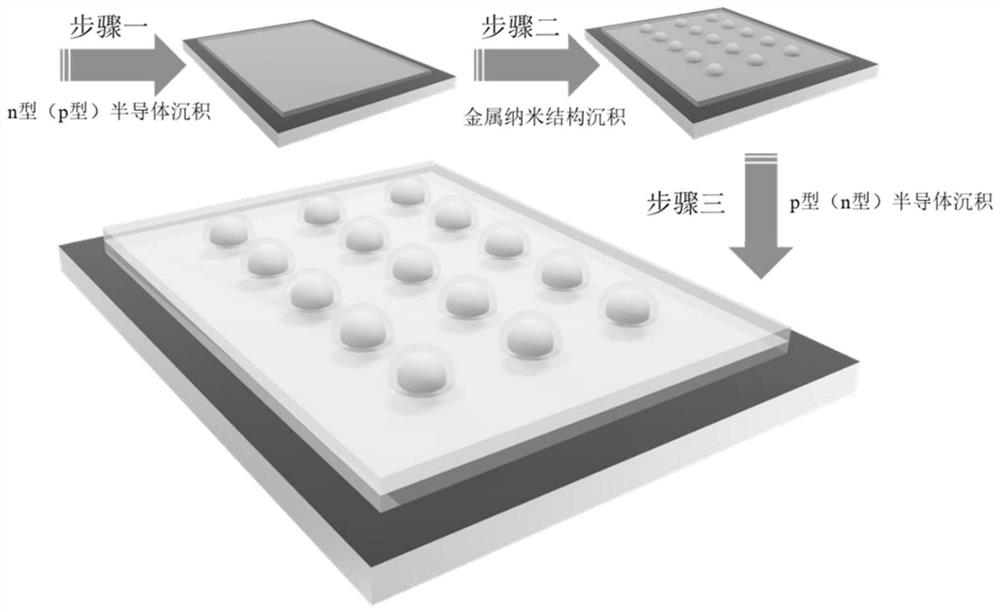

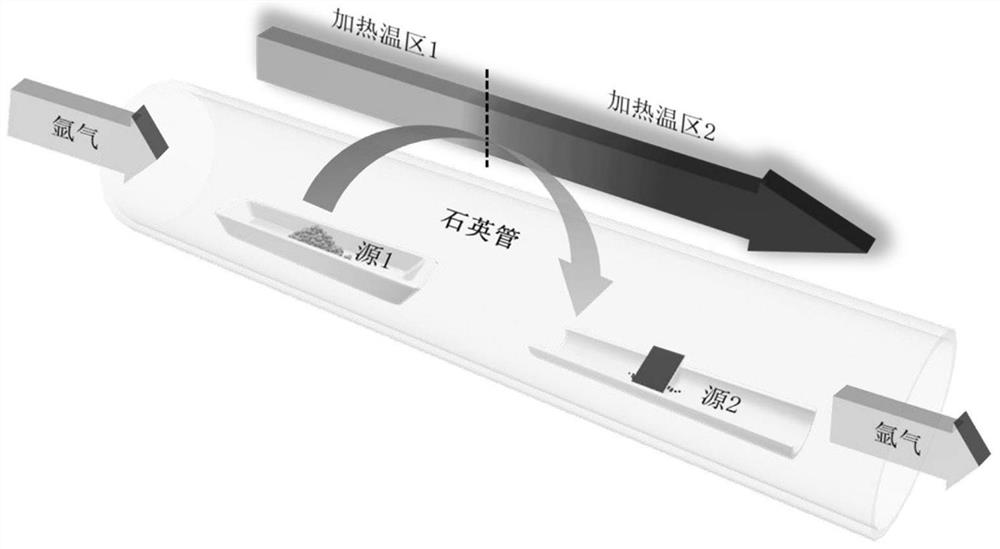

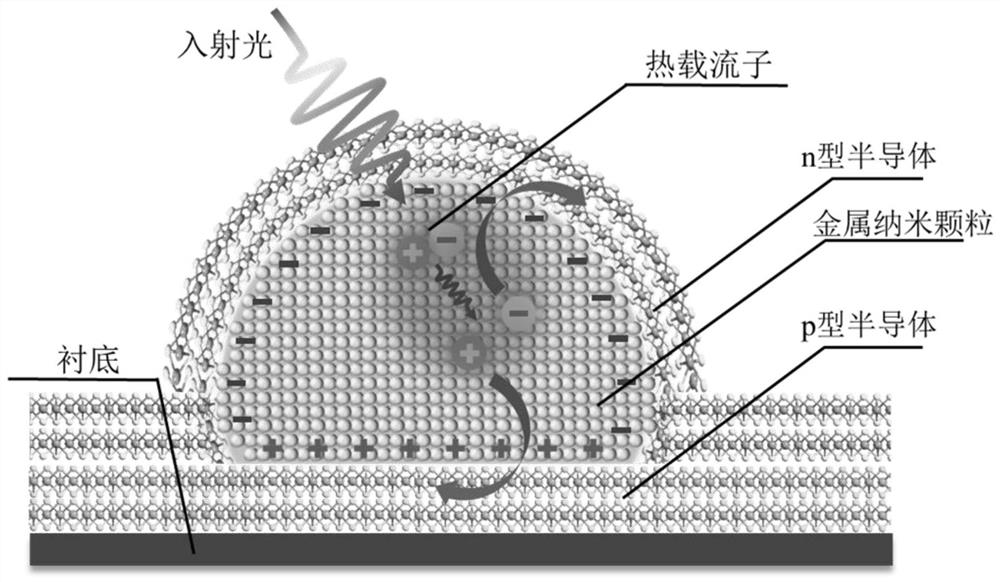

[0040] The present invention prepares a kind of n-MoS 2 / Au / p-WS2 Heterojunction. figure 2 It shows the reaction equipment and process. see Figure 1-3 , the preparation method specifically includes the following steps:

[0041] (1) Step 1: Chemical vapor deposition of n-type semiconductor material on the substrate. A three-zone horizontal tube furnace was used as the reaction vessel. A silicon wafer with a 300nm thick oxide layer on one side is selected as the substrate. MoO will be used as metal source 2 Mix the powder and NaCl powder as a growth aid at a mass ratio of 50:1 and grind thoroughly, weigh 1-2 mg of the mixture and put it into a U-shaped groove, place the side of the silicon wafer with the oxidized layer facing the source, and place it above the source. , put the U-shaped groove in the heating center. The S powder is placed in the upstream of the U-shaped groove away from the heating center, and the middle temperature zone is raised to a growth temperatur...

Embodiment 2

[0045] The present invention prepares a kind of n-MoSe 2 / Au / p-WSe 2 Heterojunction. The preparation method specifically comprises the following steps:

[0046] Repeat Example 1 with the described steps, the difference is that the non-metallic source of chemical vapor deposition is Se powder for the first time, and the holding temperature in the middle temperature zone is set to 850°C; the non-metallic source of chemical vapor deposition for the second time is Se powder, and the middle holding The temperature was set to 950°C.

Embodiment 3

[0048] The present invention prepares a kind of p-NiO / Ag / n-MoS 2 Heterojunction. The preparation method specifically comprises the following steps:

[0049] (1) Step 1: magnetron sputtering. Si(111) is selected as the substrate, and Ni with a purity of 99.999% is used as the target. Vacuumize until the vacuum degree in the chamber reaches 1.0×10 -5 After Pa, open the inflation valve, feed the carrier gas Ar with a flow rate of 20 sccm, and adjust the air pressure to 0.5 Pa after the air pressure in the chamber is stabilized. Debug the sputtering parameters, and turn on the power for 5 minutes of pre-sputtering without opening the baffle. After the pre-sputtering is completed, the reaction gas O is introduced into the chamber 2 , the flow rate is 5sccm. After the air pressure in the chamber is stabilized, adjust the air pressure to 0.5Pa. After the air pressure stabilized, open the baffle to start sputtering. After the sample is cooled, fill the chamber with air and tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com