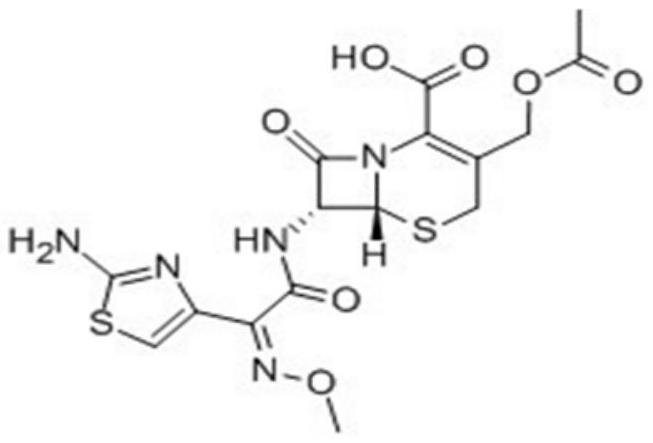

Preparation method of cefotaxime acid

A technology of cefotaxime acid and cefotaxime sodium, which is applied in the field of medicine, can solve the problems that cefotaxime acid cannot meet the production demand and affect the quality of cefotaxime sodium, and achieve a product with good quality, easy implementation and simple operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

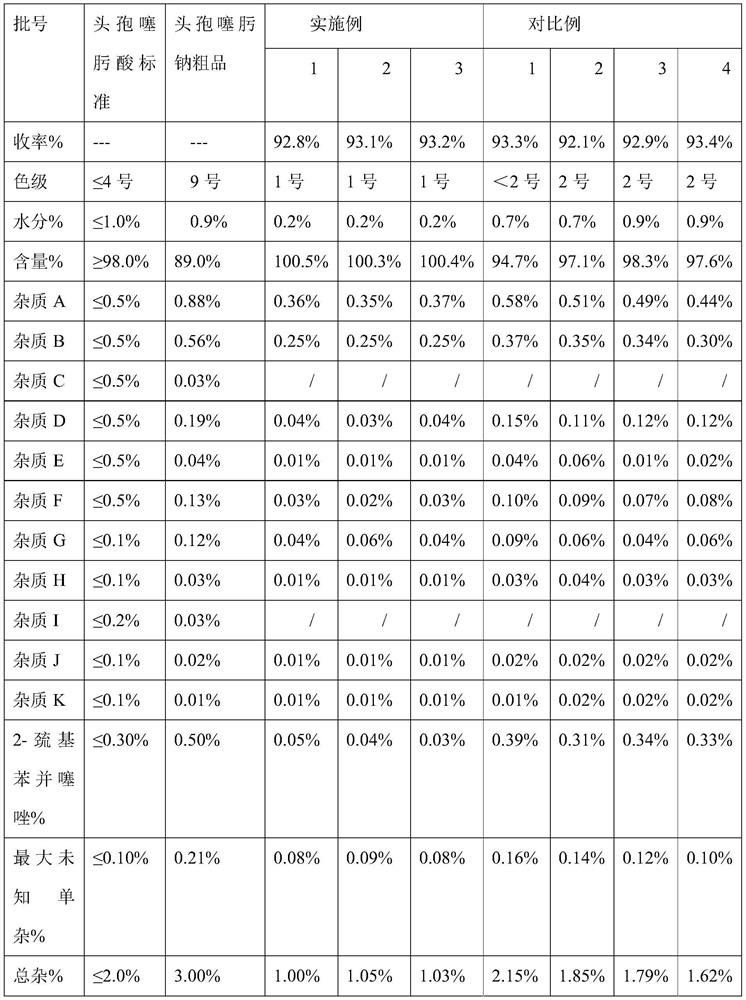

Embodiment 1

[0031] Take 40g of cefotaxime sodium, add 240mL of purified water and 200mL of acetone, stir until dissolved; control the temperature at 5°C, add 0.2g of sodium metabisulfite, adjust the pH to 4.5 with citric acid-disodium hydrogen phosphate mixture; add activated carbon and stir 30min. Filter and wash the carbon cake with 5 mL of purified water.

[0032] Combine the filtrate and lotion, add glacial acetic acid dropwise under the condition of temperature control at 10°C to adjust the pH of the system to 2.9, add 0.04 g of seed crystals and stir for 30 minutes to grow the crystals. Add glacial acetic acid to adjust the pH of the system to 2.9. At the same time, add 240mL of purified water. After 30 minutes, the temperature is lowered to 0°C and the crystal growth is continued for 30 minutes.

[0033] Filter, wash with 100 mL of acetone, and suck dry; dry at 35° C., and dry under vacuum for 1 hour to obtain 37.12 g of a white solid.

Embodiment 2

[0035] Take 40g of cefotaxime sodium, add 280mL of purified water and 240mL of acetone, stir until dissolved; control the temperature at 10°C, add 0.4g of sodium metabisulfite, citric acid-disodium hydrogen phosphate mixture to adjust the pH to 5.0; add activated carbon and stir for 30min . Filter and wash with 5 mL of purified water.

[0036] Combine the filtrate and lotion, add phosphoric acid dropwise under temperature control at 15°C to adjust the pH of the system to 3.1, add 0.4 g of seed crystals and stir for 30 minutes to grow the crystals. Add phosphoric acid to adjust the pH of the system to 3.1. At the same time, add 280 mL of purified water. After 30 minutes, cool down to 2°C and grow crystals for 60 minutes.

[0037] Filter, wash with 100 mL of acetone, and suck dry; dry at 35° C., and dry under vacuum for 1 hour to obtain 37.24 g of a white solid.

Embodiment 3

[0039] Take 40kg of cefotaxime sodium, add 260L of purified water, 220L of acetone, stir until dissolved; control the temperature at 8°C, add 0.3kg of sodium metabisulfite, citric acid-disodium hydrogen phosphate mixture to adjust the pH to 4.7; add activated carbon and stir for 30min . Filter and wash with 5L of purified water.

[0040] Combine the filtrate and lotion, add sulfuric acid dropwise under the condition of temperature control at 12°C to adjust the pH of the system to 3.0, add 0.2 kg of seed crystal and stir for 30 minutes to grow the crystal. At the same time, sulfuric acid was added to adjust the pH of the system to 3.0, and 260L of purified water was added at the same time, and the addition was completed in 30 minutes, and the temperature was lowered at 1°C to grow crystals for 45 minutes.

[0041] Filter, wash with 100L of acetone, and suck dry; dry at 35°C, and dry under vacuum for 1 hour to obtain 37.28kg of white solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com