A kind of aluminum gallium nitride based ultraviolet light emitting diode epitaxial layer structure and preparation method thereof

A light-emitting diode, AlGaN technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of difficult doping, low luminous efficiency, and high density of AlGaN-based thin films, so as to improve doping and injection efficiency, and improve luminescence. Efficiency, the effect of improving the quality of epitaxial crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

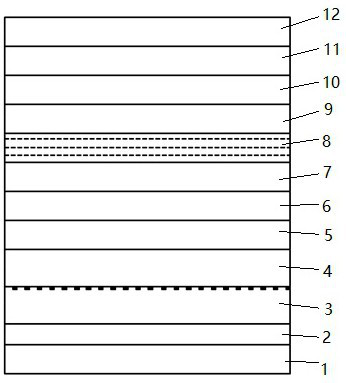

[0041] Example 1, please combine figure 1 As shown, the structure of the epitaxial layer of the AlGaN-based UV light emitting diode in this embodiment is as follows: it includes a sapphire substrate 1, a nucleation layer 2, an Al x1 Ga 1-x1 N transition layer 3, Al x2 Ga 1-x2 N buffer layer 4, Al x3 Ga 1-x3 N buffer layer 5, Al x4 Ga 1-x4 N buffer layer 6, n-type Al x5 Ga 1-x5 N layer 7, Al x6 Ga 1-x6 N / Al x7 Ga 1-x7 N multiple quantum well layer 8, p-type Al x8 Ga 1-x8 N electron blocking layer 9, p-type Al x9 Ga 1-x9 N layer 10, p-type Al x10 Ga 1-x10 N layer 11 and p-type Al x11 Ga 1-x11 N layer 12 .

[0042] please combine figure 2 shown, wherein, the sapphire substrate 1 is a double-sided polished C-plane crystal, Al x1 Ga 1-x1 The surface of the N transition layer 3 away from the sapphire substrate 1 is uniformly provided with a nanoscale cavity structure in a matrix arrangement. The nanoscale cavity structure is an inverted conical cavity 13a, an...

Embodiment 2

[0059] Example 2, the stacked structure of the AlGaN-based UV light emitting diode epitaxial layer in this example is the same as that in Example 1, wherein the sapphire substrate is a double-sided polished C-plane crystal, and nano-scale convex structures are prepared on the surface of the sapphire substrate , the nano-scale convex structure is a cylinder 14, the bottom diameter of the cylinder 14 is 30 nm, the geometric center distance of the adjacent cylinders 14 is 10-50 nm, and the height of the cylinder 14 is 30 nm. please combine Figure 4 shown, Al x1 Ga 1-x1 The side of the N transition layer away from the sapphire substrate is uniformly arranged with a nanoscale cavity structure in a matrix arrangement. The nanoscale cavity structure is a hexagonal living cavity 13b, and the longitudinal cross-sectional depth of the hexagonal column cavity 13b is 1 nm. The geometric center distance of the hexagonal prism cavity 13b is 5nm, and the distance of the top surface openin...

Embodiment 3

[0062] Embodiment 3, the stacked structure of the AlGaN-based UV light emitting diode epitaxial layer in this embodiment is the same as that of Embodiment 1, wherein, Al x1 Ga 1-x1 The side of the N transition layer away from the sapphire substrate is uniformly arranged with inverted conical cavities in a matrix arrangement. The longitudinal section depth of the inverted conical cavities is 2 nm, and the geometric center spacing of adjacent inverted conical cavities is 3 nm. The maximum opening distance (diameter in this example) of the top surface of the cavity is 3 nm. The nucleation layer is AlN with a thickness of 100 nm, Al x1 Ga 1-x1 The thickness of the N transition layer is 1000 nm, the Al x2 Ga 1-x2 The thickness of the N buffer layer is 1000 nm, the Al x3 Ga 1-x3 The thickness of the N buffer layer is 500 nm, the Al x4 Ga 1-x4 The thickness of the N buffer layer is 300 nm, and the n-type Al x5 Ga 1-x5 The thickness of the N layer is 1000 nm, Al x6 Ga 1-x6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com