Preparation and application of zinc negative electrode material of novel aqueous zinc ion battery

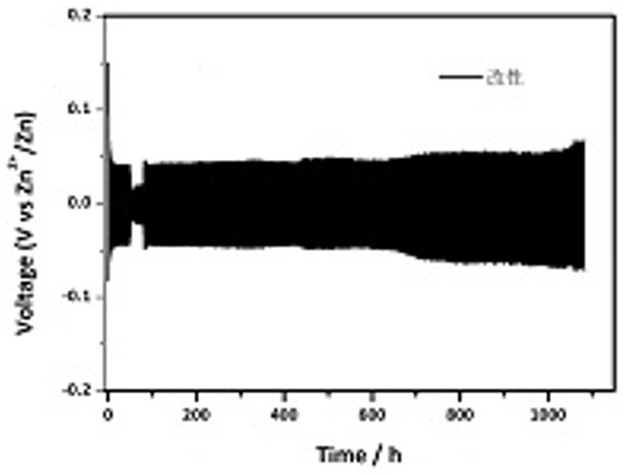

A zinc ion battery and zinc negative electrode technology, which is applied in electrode manufacturing, battery electrode, secondary battery manufacturing, etc., can solve the problems of restricting the development of economical water-based zinc ion batteries, high production costs, complicated procedures, etc., and achieve long-term improvement. Effect of stability and lifetime, high dielectric constant, uniform ion flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

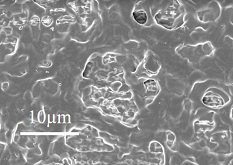

[0025] This embodiment provides a zinc negative electrode material for a novel aqueous zinc-ion battery, comprising the following steps:

[0026] Put 0.1g of polyvinyl chloride powder and 0.1g of zinc trifluoromethanesulfonate powder in a 15mL glass bottle, add 3g of N,N-dimethylformamide solvent, and stir in an oil bath at 85°C for 2 hours , cooling down at room temperature to form a uniform polymer coating solution, which is stored in vacuum and ready for use.

Embodiment 2

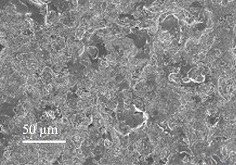

[0028] This embodiment provides a zinc negative electrode material for a novel aqueous zinc-ion battery, comprising the following steps:

[0029] Put 0.2g of polyvinyl chloride powder and 0.1g of zinc trifluoromethanesulfonate powder in a 15mL glass bottle, add 3g of N,N-dimethylformamide solvent, and stir in an oil bath at 85°C for 2 hours , cooling down at room temperature to form a uniform polymer coating solution, which is stored in vacuum and ready for use.

Embodiment 3

[0031] This embodiment provides a zinc negative electrode material for a novel aqueous zinc-ion battery, comprising the following steps:

[0032] Put 0.1g of polyvinyl chloride powder and 0.1g of zinc trifluoromethanesulfonate powder in a 15mL glass bottle, add 6g of N,N-dimethylformamide solvent, and stir in an oil bath at 85°C for 2 hours , cooling down at room temperature to form a uniform polymer coating solution, which is stored in vacuum and ready for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com