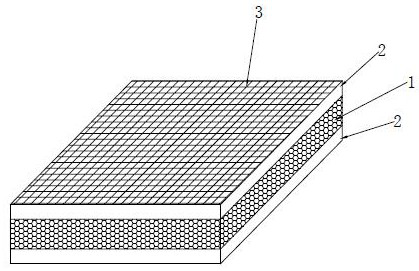

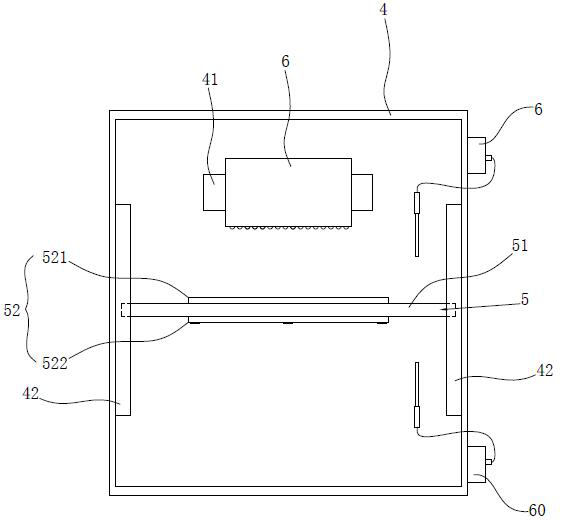

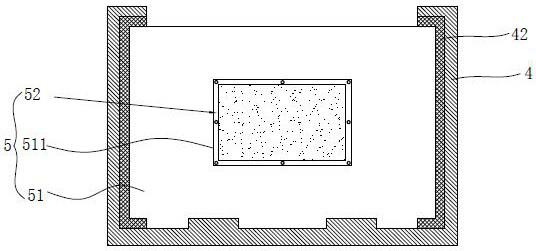

Thermal runaway protection low-thermal-conductivity mica composite part applied between battery cells and preparation method of thermal runaway protection low-thermal-conductivity mica composite part

A technology with low thermal conductivity and thermal runaway, which is applied in electrical components, battery pack parts, chemical instruments and methods, etc. It can solve problems affecting the thermal runaway protection performance of the battery module, high thermal conductivity, and poor thermal insulation performance of the battery cell. , to achieve good thermal runaway protection performance, good heat insulation and flame retardant performance, and the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0049] Preparation of synthetic fluorphlogopite aggregates: Grinding and sieving synthetic fluorphlogopite, sieving with a 5000-mesh sieve, the resulting sieved product is <2.6 micron synthetic fluorphlogopite, using a 1340-mesh sieve, and the resulting sieved The sieve is 2.6-10 micron synthetic fluorophlogopite, which is sieved by 500 mesh, and the obtained sieve is 10-25 micron synthetic fluorphlogopite, which is sieved by 400 mesh, and the obtained sieve is 25-38 Micron synthetic fluorophlogopite, sieved by 270 mesh, the sieved product is 38-53 micron synthetic fluorophlogopite, sieved by 180 mesh, and the obtained sieve is 53-80 micron synthetic fluorophlogopite , the sieve retentate can be ground and sieved again; according to 5% < 2.6 micron synthetic fluorophlogopite, 10% 2.6-10 micron synthetic fluorophlogopite, 20% 10-25 micron synthetic fluorogold Mica, 50% 25-38 micron synthetic fluorphlogopite, 10% 38-53 micron synthetic fluorphlogopite, 5% 53-80 micron synthetic ...

preparation example 2

[0059] The difference between Preparation Example 2 and Preparation Example 1 is that the surface modified composite mica composition is composed of 40 parts of synthetic fluorophlogopite aggregates, 50 parts of phlogopite aggregates, 20 parts of muscovite aggregates, 10 parts of Prepared from isopropyl tris(dioctyl phosphate acyloxy) titanate.

preparation example 3

[0061] The difference between Preparation Example 3 and Preparation Example 1 is that the surface modified composite mica composition is composed of 50 parts of synthetic fluorophlogopite aggregates, 50 parts of phlogopite aggregates, 20 parts of muscovite aggregates, 10 parts of Prepared from isopropyl tris(dioctyl phosphate acyloxy) titanate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com