Hydrogen impurity purification device for fuel cell

A purification device, fuel cell technology, applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of large occupied area, limited use, complex equipment, etc., to achieve simple device, prevent potential deviation, and complexity. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

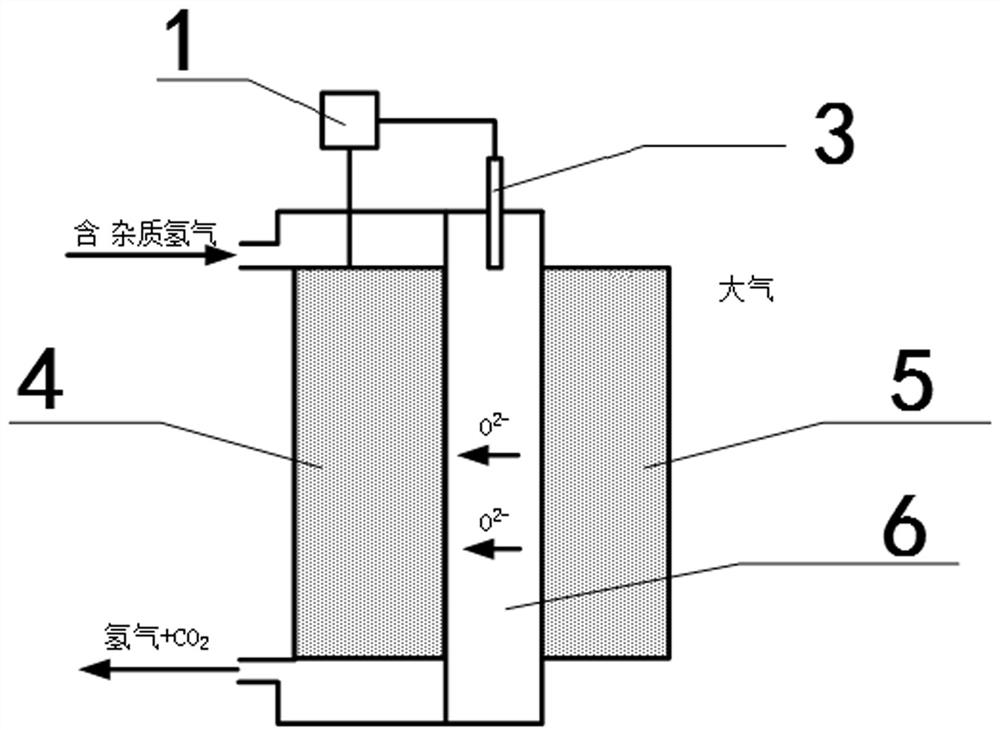

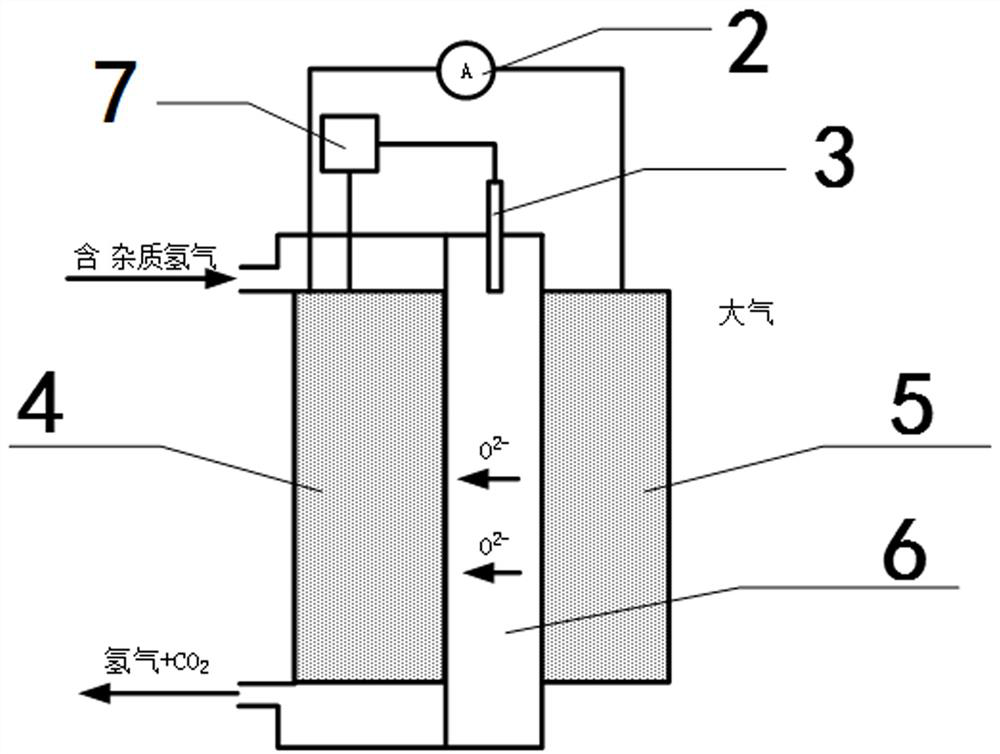

[0051] An embodiment of the present invention discloses a hydrogen impurity purification device for a fuel cell, including a solid-state electrochemical reactor and a controller.

[0052] The solid state electrochemical reactor further comprises an anode diffusion electrode layer 4 , an electrolyte layer 6 , a cathode diffusion electrode layer 5 and a reference electrode 3 . The electrolyte layer 6 serves to transport oxygen ions. The two sides of the anode diffusion electrode layer 4 are respectively provided with an inlet for hydrogen gas to be purified and an outlet for hydrogen gas after purification. The cathode diffusion electrode layer 5 is in contact with air, and is separated from the anode diffusion electrode layer 4 by an electrolyte layer 6 . The reference electrode 3 is located in the electrolyte layer 6, such as figure 1 shown.

[0053] The controller is used to control the potential of the anode diffusion electrode layer 4 of the solid-state electrochemical r...

Embodiment 2

[0056] Improvements are made on the basis of Example 1, and the impurities include at least one of carbon monoxide, hydrogen sulfide, nitrogen oxides, and ammonia. Also, the hydrogen purification device is used to convert carbon monoxide (CO) into carbon dioxide (CO 2 ), or, hydrogen sulfide (H 2 S) converted to sulfuric acid (H 2 SO 4 ), alternatively, nitrogen oxides (NO X ) into nitrogen (N 2 ) and oxygen (O 2 ), or, ammonia (NH 3 ) into nitrogen (N 2 ) and water.

[0057] Preferably, a catalyst is distributed in both the anode diffusion electrode layer 4 and the cathode diffusion electrode layer 5; and the catalyst is a metal oxide.

[0058] Preferably, for carbon monoxide or hydrogen sulphide impurities, the catalyst comprises nickel oxide; for nitrogen oxides or ammonia impurities, the catalyst comprises zirconia.

[0059] Preferably, preferably, the ionic electrolyte can adopt but not limited to Bi 2 V 0.9 Cu 0.1 o 5.35-δ (See "Bi 2 V 0.9 Cu 0.1 o 5.35-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com