High-energy-storage-density wide-working-temperature component gradient structure thin film and preparation method thereof

A technology with wide operating temperature and high energy storage density, applied in metal material coating process, components of fixed capacitors, vacuum evaporation coating, etc., can solve the problems of low operating temperature and low energy storage density of lead-free films, Achieve the effect of reducing interface polarization, increasing energy storage efficiency and operating temperature, reducing defects and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the film with high energy storage density and wide working temperature composition gradient structure of the present invention comprises the following steps:

[0033] Step 1. Target preparation: for growing BaHf x Ti 1-x o 3 The ceramic target of the thin film adopts BaCO with a purity level of 4-5N 3 Powder, HfO 2 Powder and TiO 2 powder by BaHf x Ti 1-x o 3 The stoichiometric ratio, where 0.17≤x≤0.32, is prepared by traditional ceramic technology; when preparing ceramic targets, the sintering temperature is lower than the phase formation temperature of each system by 100-200 °C.

[0034] Step 2, put the substrate, vacuum: Nb:SrTiO 3 The substrate is placed on the heating platform, and the vacuum degree in the deposition chamber is less than 1×10 by using a mechanical pump and a molecular pump. -5 mbar.

[0035] Step 3. Ventilate and heat up: Infuse 200 mbar of argon-oxygen mixed gas with a volume ratio of 1 / 1, then raise the tempera...

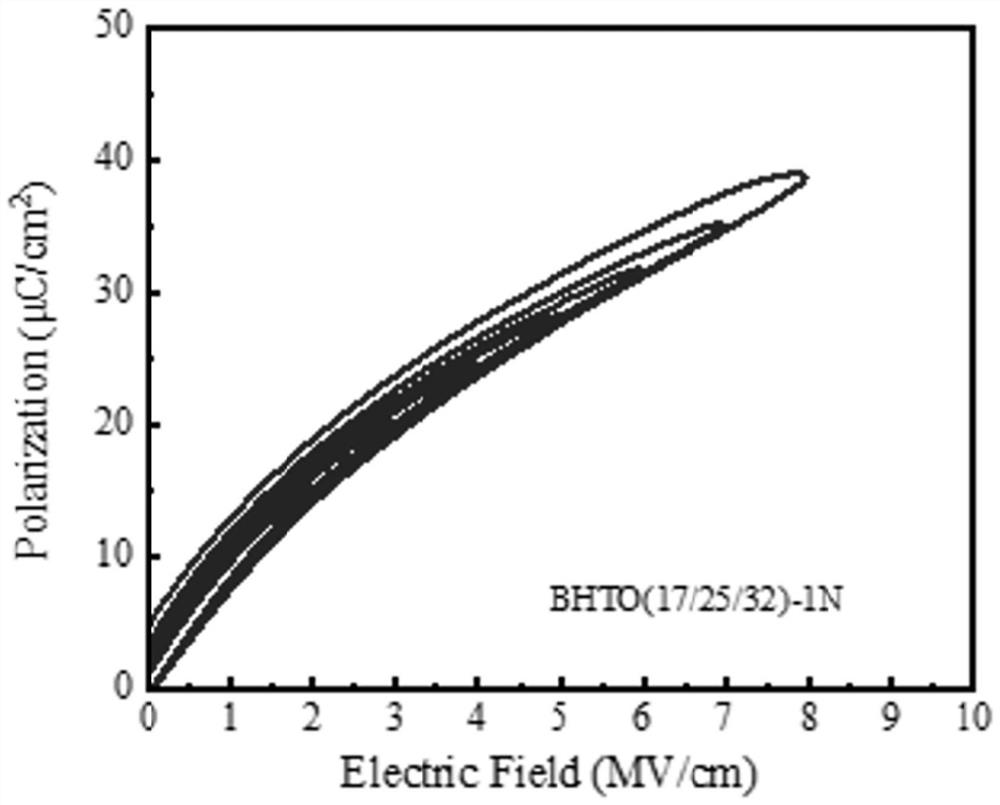

Embodiment 1

[0041] The preparation method of the film with high energy storage density and wide working temperature composition gradient structure in this embodiment includes the following steps:

[0042] Step 1. Target preparation: for growing BaHf 0.17 Ti 0.83 o 3 / BaHf 0.25 Ti 0.75 o 3 / BaHf 0.32 Ti 0.68 o 3 The ceramic target of the composition gradient structure multilayer film with a cycle number of 1 uses BaCO with a purity level of 5N 3 Powder, HfO 2 Powder and TiO 2 The powder is prepared by traditional ceramic technology according to the ratio; when preparing ceramic targets, the sintering temperature is lower than the phase formation temperature of each system by 100 °C.

[0043] Step 2, put the substrate, vacuum: Nb:SrTiO 3 The substrate is placed on the heating platform, and the vacuum degree in the deposition chamber is less than 1×10 by using a mechanical pump and a molecular pump. -5 mbar.

[0044] Step 3. Ventilate and heat up: Infuse 200 mbar of argon gas an...

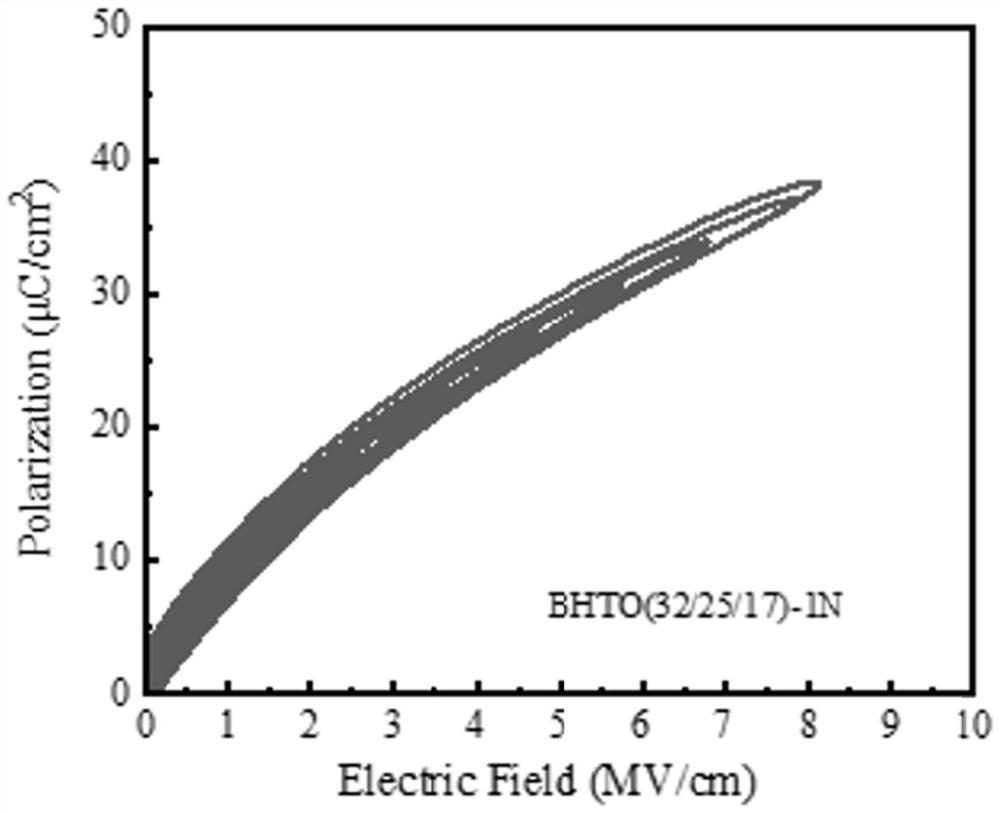

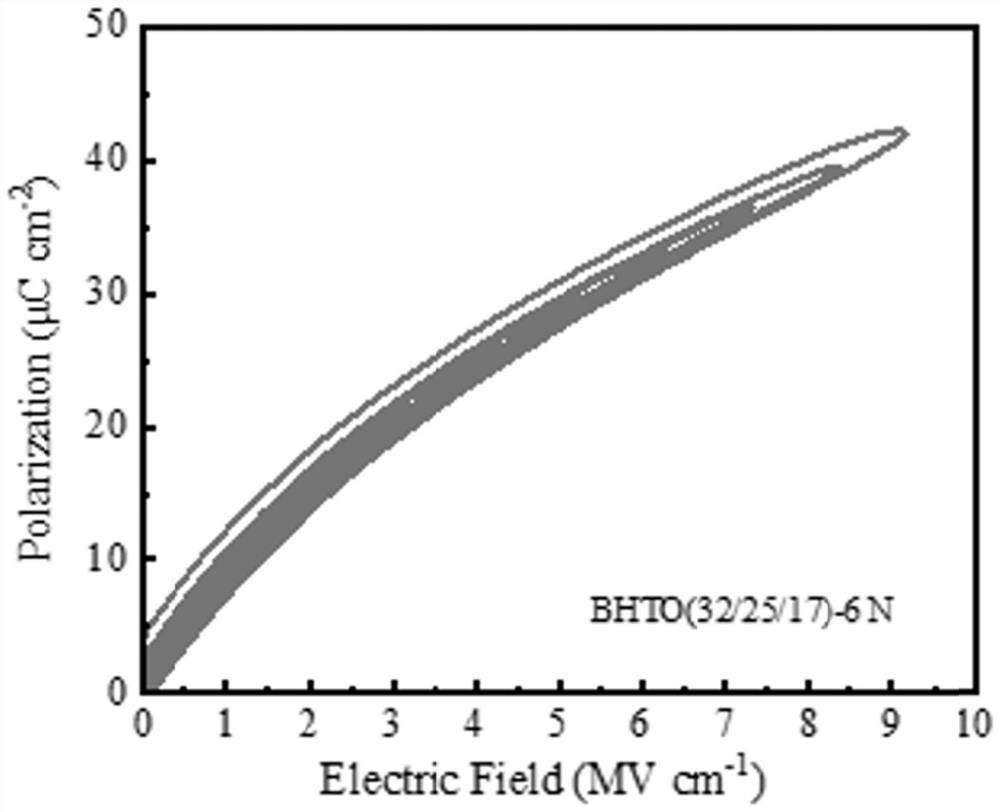

Embodiment 2

[0051] The preparation method of the film with high energy storage density and wide working temperature composition gradient structure in this embodiment includes the following steps:

[0052] Step 1. Target preparation: for growing BaHf 0.32 Ti 0.68 o 3 / BaHf 0.25 Ti 0.75 o 3 / BaHf 0.17 Ti 0.83 o 3 The ceramic target of the composition gradient structure film with a cycle number of 1 uses BaCO with a purity level of 5N 3 Powder, HfO 2 Powder and TiO 2 The powder is prepared by traditional ceramic technology according to the ratio; when preparing ceramic targets, the sintering temperature is lower than the phase formation temperature of each system by 100 °C.

[0053] Step 2, put the substrate, vacuum: Nb:SrTiO 3 The substrate is placed on the heating platform, and the vacuum degree in the deposition chamber is less than 1×10 by using a mechanical pump and a molecular pump. -5 mbar.

[0054] Step 3. Ventilation and temperature rise: 200 mbar of argon gas and oxyge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakdown field strength | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com