Dual-energy X-ray bone mineral density detection method based on moving least square algorithm

A technology of moving least squares and detection methods, which is applied in the fields of radiological diagnostic instruments, medical science, and diagnosis, and can solve problems such as high requirements for fitting coefficients, increased errors, and large amount of polynomial fitting calculations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical solutions in the embodiments of the present invention will be described clearly and in detail below with reference to the drawings in the embodiments of the present invention. The described embodiments are only some of the embodiments of the invention.

[0055] The technical scheme that the present invention solves the problems of the technologies described above is:

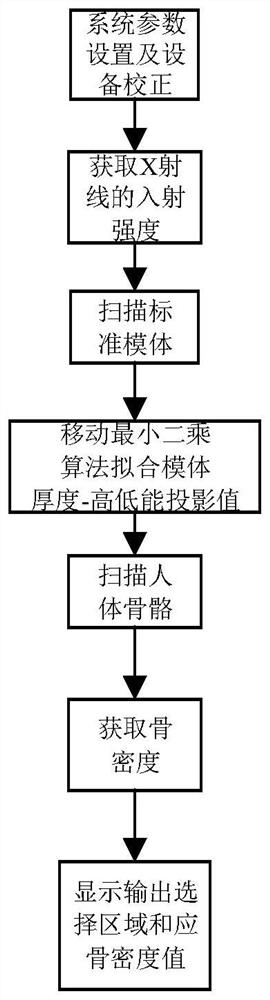

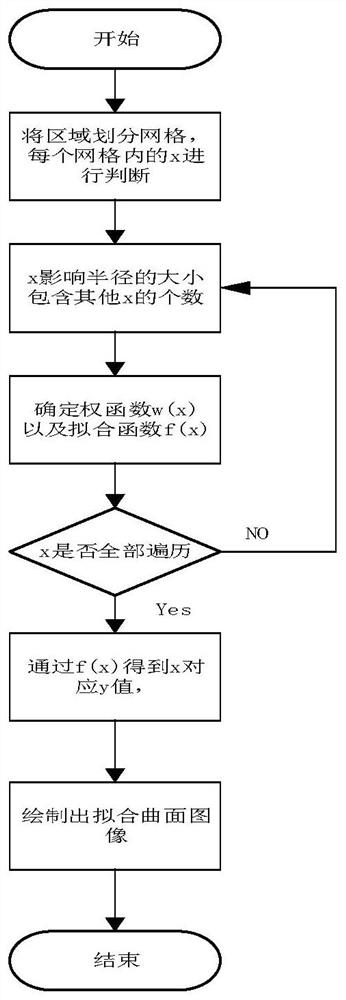

[0056] The present invention proposes a dual-energy X-ray bone density detection system based on the moving least squares algorithm to solve the error impact of the photon counting detector pixel inhomogeneity on the traditional bone density fitting algorithm. This system improves the bone density measurement accuracy, Effectively correct detector pixel inhomogeneity and optimize detector performance.

[0057] In order to achieve the above object, the implementation of the present invention provides the following technical solutions.

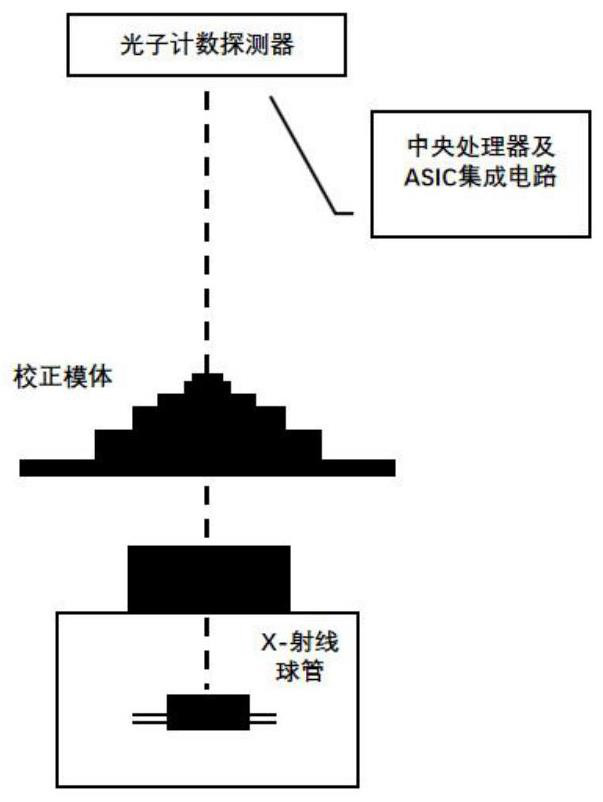

[0058] 1. Build an optical platform as shown in Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com