High-temperature-resistant and low-density aluminum oxide nanorod aerogel and preparation method thereof

A kind of aluminum oxide nano and airgel technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of insufficient temperature resistance, achieve improved temperature resistance, high specific surface area retention rate, avoid sintering and large specific surface area Falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

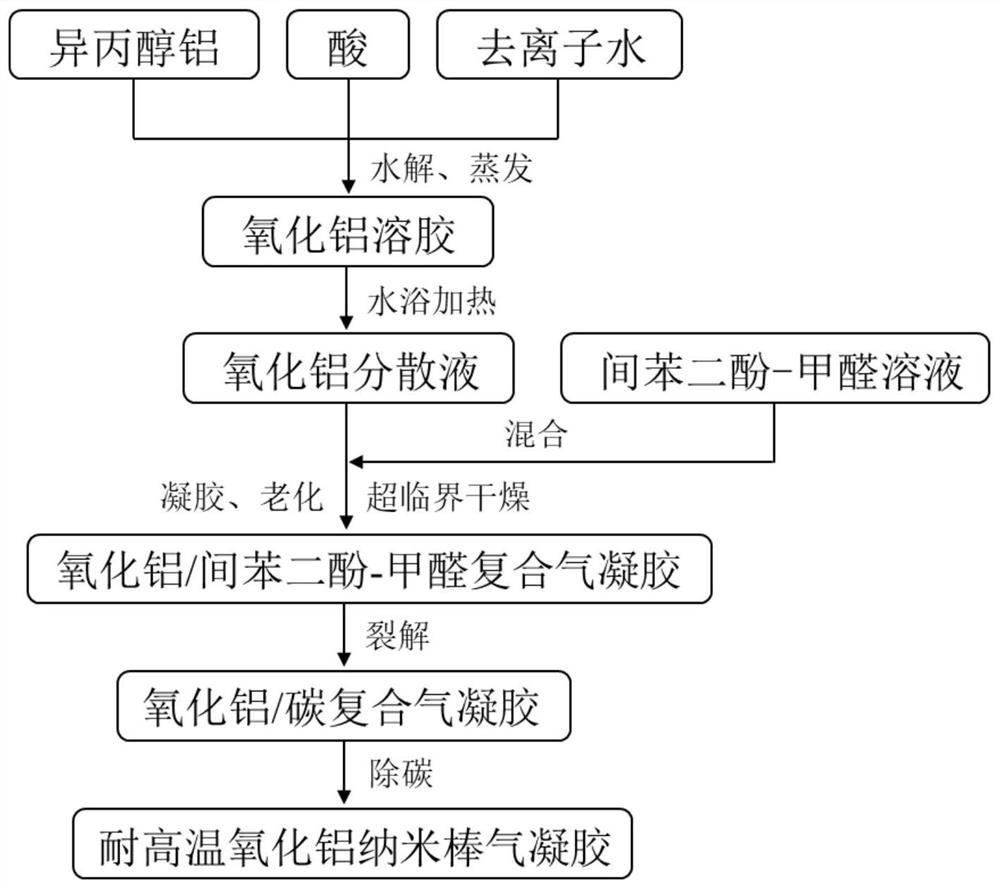

[0026] The present invention proposes a kind of preparation method of aluminum oxide nanorod aerogel, such as figure 1 shown, including the following steps:

[0027] S1: Aluminum isopropoxide (Al(OCHCH 3 CH 3 ) 3 ) mixed with deionized water under stirring conditions, heated to 50-80°C, and kept at 50-80°C for 0.5-3h, then heated from 50-80°C to 85-100°C, and heated at 85-100°C Keeping it warm for 0.5-2 hours, adding an acid substance as a shape regulator, performing a hydrothermal reaction, cooling to room temperature, and obtaining aluminum oxide nanorods.

[0028] Incubate at 50-80°C for 0.5-3 hours to obtain a fully hydrolyzed alumina solution.

[0029] Incubate at 85-100°C for 0.5-2 hours to evaporate the isopropanol produced by hydrolysis.

[0030] Preferably, the molar ratio of the aluminum isopropoxide to deionized water is (10-50):1; the molar ratio of the acidic substance to the aluminum isopropoxide is 4-18:1.

[0031] Preferably, the acid is one of dilute hyd...

Embodiment 1

[0048] This embodiment provides a method for preparing alumina nanorod airgel, comprising the following steps:

[0049] S1: Aluminum isopropoxide (Al(OCHCH 3 CH 3 ) 3 ) and deionized water (H 2 O) After mixing under stirring conditions, heat to 70°C and keep it warm for 5h to obtain a fully hydrolyzed alumina hydrolyzate; further raise the temperature to 90°C and keep it warm for 0.5h, evaporate the isopropanol produced by hydrolysis, and get alumina sol ; The alumina sol and acetic acid are fully mixed according to the ratio of 10:1, then placed in a hydrothermal kettle, heated to 160 ° C and kept for 10 hours, and then cooled to room temperature to obtain a dispersion of alumina nanorods.

[0050] S2: Fully mix resorcinol and deionized water under stirring, add sodium carbonate solution dropwise to the solution after fully dissolved, stir for 30 minutes, add a certain amount of formaldehyde to the mixture, stir for a period of time Stand still for 1 hour to obtain resorc...

Embodiment 2

[0055] This example provides a method for preparing alumina nanorod airgel. Compared with Example 1, in step S4, the alumina / carbon composite airgel material is placed in an air atmosphere and the temperature is 800 ° C. Under heat treatment for 5 hours, a high temperature resistant, low density alumina nanorod aerogel was obtained. Other processes are with embodiment 1.

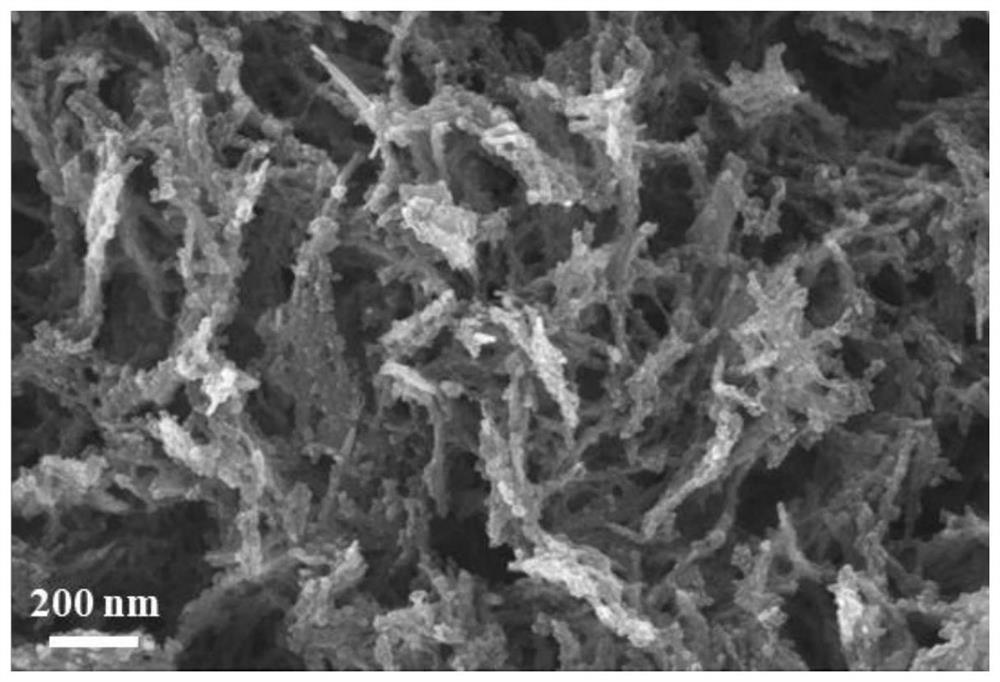

[0056] The high-temperature-resistant alumina nanorod aerogel prepared in this example was tested for temperature resistance, and it was found that the specific surface area of the sample after 1300°C heat test (air atmosphere) for 30 minutes was 72m 2 / g, there is no obvious change on the surface of the sample and no cracking and structural collapse; the specific surface area of the sample after 1400 ℃ heat assessment (air atmosphere) for 30 minutes is 26m 2 / g, there is no obvious change on the surface of the sample and no cracking or structural collapse occurs, indicating that it can withstand high t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com