Preparation method and application of chitosan-fish skin gelatin composite film coating agent

A technology of fish skin gelatin and chitosan, which is applied in application, protection of fruits/vegetables with coating protection layer, food preservation, etc. It can solve the problems of passion fruit surface shrinkage, fruit commercial rate decline, and weaken fruit disease resistance, etc. , to achieve the effects of enhancing stability, reducing respiratory intensity and ethylene release rate, and prolonging the storage period at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

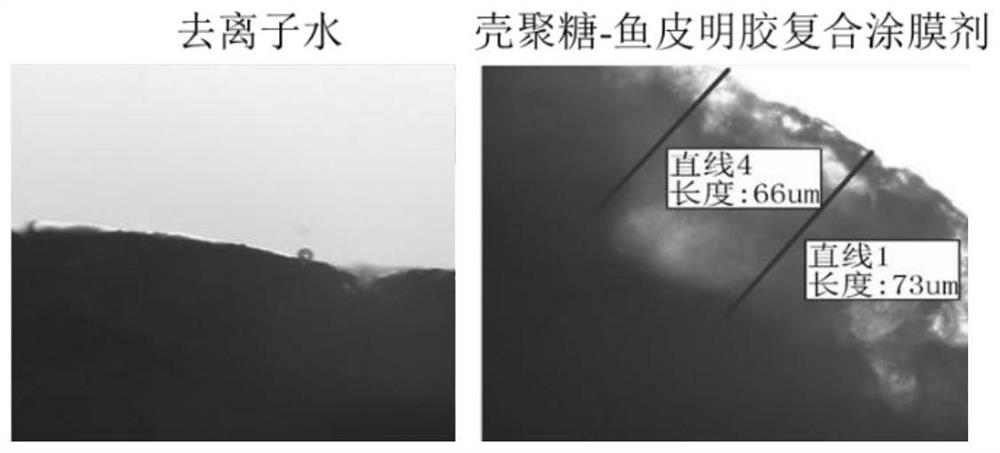

[0030] Preparation of chitosan-fish skin gelatin composite coating agent:

[0031] Add 0.6mol / L HCl (mass ratio of dry fish skin to 0.6mol / L HCl: 1:5) to 10 g of dried fish skin after fat removal for 15 minutes, then rinse until neutral, add 90 mL of deionized water, and set the temperature at 95 ° C, 40 KHz Ultrasonic hydrolysis at constant temperature for 3 hours under the conditions, then adding glycerin, chitosan and ε-polylysine to obtain a mixture, and stirring the mixture at room temperature for 30 minutes, the chitosan-fish skin gelatin composite coating film can be obtained; wherein glycerin, chitosan and ε-polylysine The mass fractions of ε-polylysine in the mixture were 2%, 1% and 0.5%, respectively.

experiment example 1

[0033] The mass fraction of glycerol in the mixture is adjusted to 0%, 0.5%, 1%, 1.5%, 2%, 2.5% and 3% respectively, and other operations are the same as in Example 1 to prepare chitosan-fish skin gelatin composite coatings respectively. film agent.

[0034] The mechanical properties of the prepared chitosan-fish skin gelatin composite coating agent are evaluated, and the results are shown in table 1. It can be seen that when the mass fraction of glycerol in the mixture is 2%, the chitosan-fish skin gelatin composite The mechanical properties of the coating agent are the best.

[0035] Table 1

[0036] Glycerin addition ratio Stretch distance (mm) Elongation at break (%) 0.5% 15.36±1.27 56.88±1.65 1% 19.84±1.45 68.74±1.37 1.5% 21.99±1.23 74.93±1.78 2% 22.03±1.88 75.35±2.85 2.5% 21.03±1.97 74.21±1.04 3% 20.43±2.24 70.69±2.49

Embodiment 2

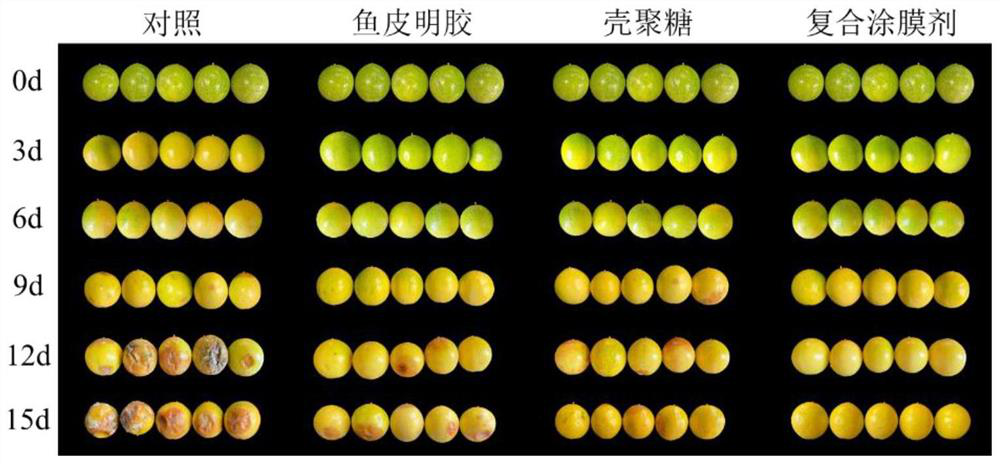

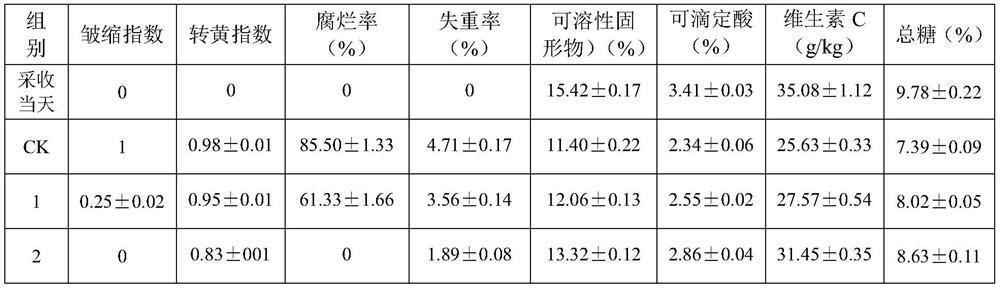

[0050] Select the healthy passion fruit fruit with roughly the same degree of maturity, no damage by diseases and insect pests and damage, respectively adopt 1% chitosan, the chitosan-fish skin gelatin composite coating film prepared by embodiment 1, the fish skin gelatin prepared by comparative examples 1-4 Or composite coating film for coating treatment, a group of clear water as a control (see Table 2 for details), after packaging, store in a constant temperature and humidity incubator at 25 (± 1) °C and 85% humidity, and compare the relevant fruits after 12 days of storage Storage effect and quality evaluation index (Table 3).

[0051] Table 2

[0052] group coating film Preparation CK clear water / 1 1% Chitosan Chitosan (CTS) 40g dissolved in 360g water (containing 1% acetic acid) 2 Example 1 Same as Example 1 3 Comparative example 1 Same as Comparative Example 1 4 Comparative example 2 Same as comparative example 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com