Solidified yoghurt and production process thereof

A production process and technology for yogurt, applied in the directions of milk preparations, dairy products, applications, etc., can solve the problems of single taste and no health care value, and achieve the effect of unique flavor, improved edible value and nutritional value, and good health care value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

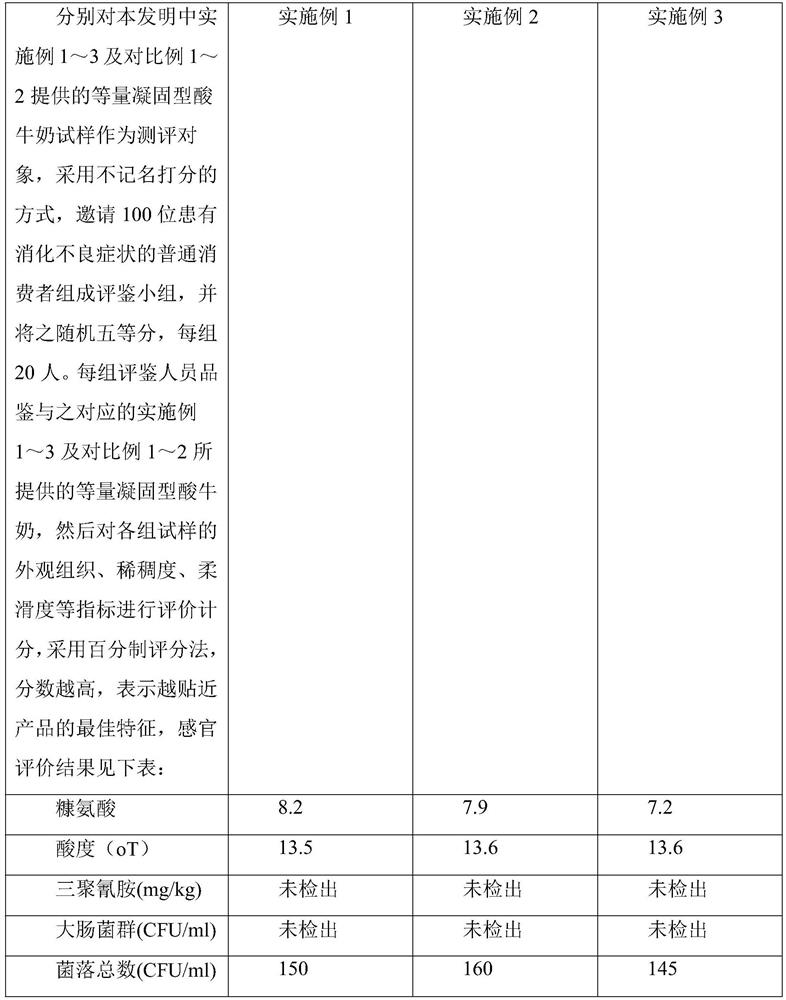

Examples

Embodiment 1

[0030] A coagulated yogurt, the coagulated yogurt comprises the following raw materials in percentage by weight: 3% cream, 2% sweetened condensed milk, 0.04% jam, 0.02% whey protein powder, 0.03% compound nutritional fruit powder, 0.8% milk protein powder, 60U / t fermented bacteria, 6% white granulated sugar, 0.3% edible gum, and the balance is fresh milk.

[0031] The preparation method of compound nutritional fruit powder comprises the following steps:

[0032] ⅰ. After peeling seabuckthorn fruit, papaya and pineapple respectively, clean the pulp, then weigh an appropriate amount of sea buckthorn fruit, papaya and pineapple pulp in a weight ratio of 0.5:1.0:0.3, and transfer the mixed pulp into Beating in the homogenizer;

[0033] ii. After beating is completed, add β-cyclodextrin with a mass of 0.5% of the dry weight of the mixed pulp to the obtained mixed pulp, and homogenize it under a pressure of 20 MPa; , fill the obtained mixed slurry, and pre-freeze it at a temperatu...

Embodiment 2

[0045] Compared with Example 1, this example differs in that the specific proportions of the components in the coagulated yogurt are different, specifically: 6% butter, 3% sweetened condensed milk, 0.05% jam, 0.03% whey protein powder, 0.04% compound nutritious fruit powder, 1.8% milk protein powder, 80U / t fermentation strain, 8% glucose, 0.5% edible gum, and the balance is skim milk.

[0046] The jam is mango jam, and the net fruit content in the jam is 40wt%, and the particle diameter of the fruit is 4mm.

[0047] The fermentation strain is compounded by Lactobacillus bulgaricus and Streptococcus thermophilus at a mass ratio of 1:3.

[0048] Edible gelatin is made of gelatin and agar in a mass ratio of 10:1.

Embodiment 3

[0050] Compared with Example 1, this example differs in that the specific proportions of the components in the coagulated yogurt are different, specifically: 8% cream, 5% sweetened condensed milk, 0.06% jam, 0.04% whey Protein powder, 0.05% compound nutritional fruit powder, 2.5% milk protein powder, 100U / t fermented bacteria, 10% maltose, 0.8% edible gum, and the rest is reconstituted milk.

[0051] The jam is blueberry jam, and the net fruit content in the jam is 45wt%, and the particle diameter of the fruit is 6mm.

[0052] The fermentation strain is compounded by Lactobacillus bulgaricus and Streptococcus thermophilus at a mass ratio of 1:3.5.

[0053] Edible gelatin is made of gelatin and agar at a mass ratio of 12:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com