Production method for reducing pellet pulverization

A production method and pelletizing technology, which are applied in the production field of reducing pellet pulverization, can solve the problems of high manufacturing cost and investment time cost, low applicability, etc., achieve low manufacturing cost, facilitate water vapor evaporation, improve The effect of burst temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

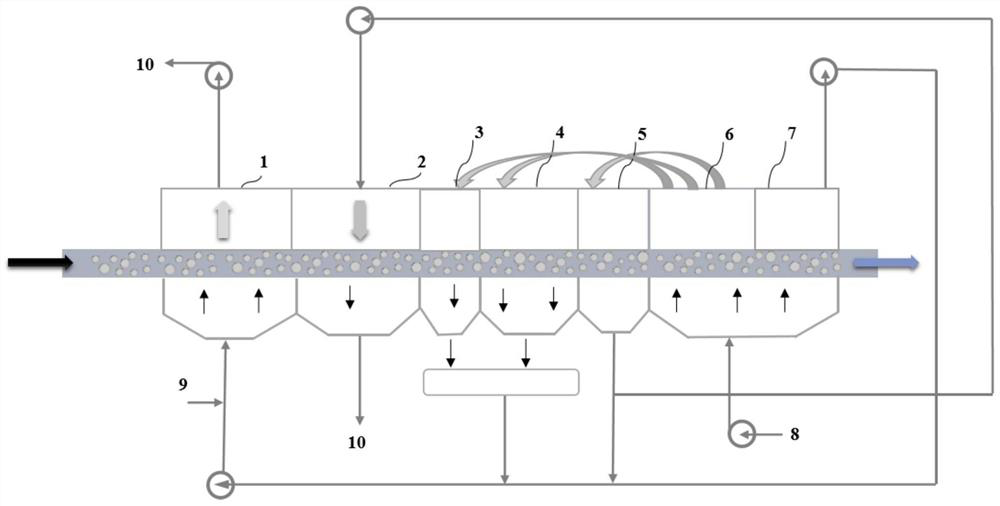

Method used

Image

Examples

Embodiment 1

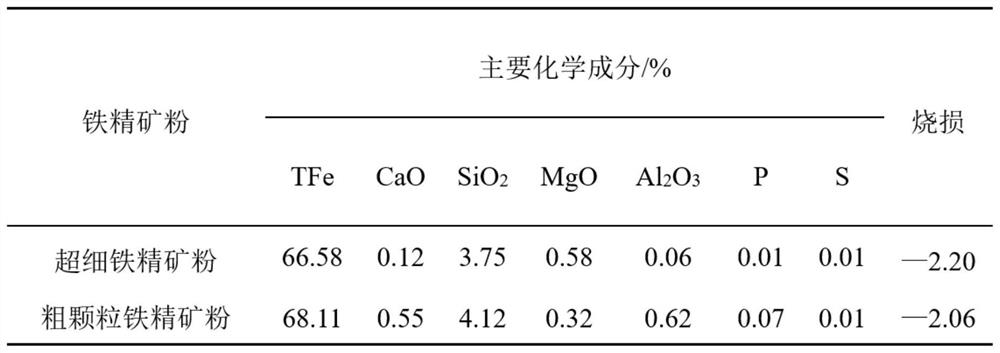

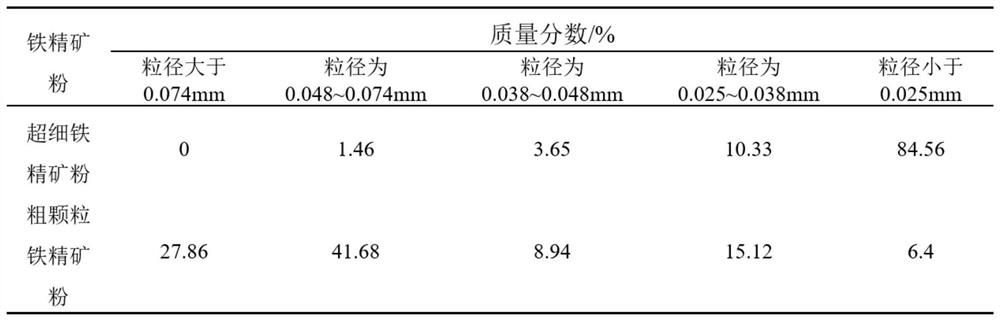

[0051] 1.1. Ordinary drying at low temperature: First, fully mix 100% ultra-fine iron concentrate powder and 2.0% bentonite agent, add 6% water to mix, control the moisture content of the raw balls to 7% during the pelletizing process, and the pelletizing time is 18 minutes, including 2 minutes of consolidation, sieving to control the diameter of the green balls at 12.5-13.5mm; then, the green balls are subjected to low-temperature drying treatment, the wind speed of blast drying is controlled to be 1.5m / s, the drying temperature is 155°C, and the drying time is 2min.

[0052] 1.2 Drying at low temperature and high air volume: The batching and green ball making part are the same as in Example 1.1, and the improved belt roaster of the present invention is used to carry out blast drying treatment (that is, preheating section, roasting section, soaking section and cooling second section) The air volume is adjusted to the blast drying section), which effectively increases the air ...

Embodiment 2

[0057] 2.1. Ordinary drying at low temperature: 100% ultra-fine iron ore concentrate powder, mixed with slaked lime calculated at 1.2 alkalinity, and then mixed with 6% water to fully mix. 2 minutes, the diameter of green balls is 12.5 ~ 13.5mm, ordinary drying at low temperature, the wind speed of blast drying is 1.5m / s, the drying temperature is 158°C, and the drying time is 2 minutes.

[0058] 2.2. Drying at low temperature and large air volume: the ingredients and green pellets are the same as in Example 2.1, and the blast drying method of the present invention is used for drying treatment. The blast drying wind speed is controlled to be 3m / s, the drying temperature is 158°C, and the drying time is controlled. for 2min.

Embodiment 3

[0063] 3.1 Ordinary drying at low temperature: 100% coarse iron ore powder, add 2.0% bentonite, add 6% water to mix thoroughly, the water content of green balls is 8%, the time for pelletizing is 16 minutes, and then consolidated for 2 minutes, the diameter of green balls is 12.5 ~ 13.5mm, low temperature ordinary drying blast drying wind speed 1.5m / s, drying temperature 152 ℃, drying time 2min.

[0064] 3.2 Drying at low temperature and large air volume: the ingredients and green pellets are the same as in Example 3.1, and the blast drying method of the present invention is used for drying treatment. The blast drying wind speed is controlled to be 3m / s, the drying temperature is 152°C, and the drying time is 2min .

PUM

| Property | Measurement | Unit |

|---|---|---|

| burst temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com