Metal anode, method for manufacturing metal anode, and secondary battery provided with metal anode

A metal anode, secondary battery technology, applied in the direction of secondary batteries, fuel cell type half cells and secondary battery type half cells, negative electrodes, etc. Effect of crystal short circuit, suppression of negative electrode capacity, and prevention of reduction in current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0188]In the above, the metal negative electrode and the production method thereof according to one embodiment of the present invention have been described by taking the zinc negative electrode as an example, but the present invention is not limited to these specific examples at all. As long as the reaction space confinement effect based on the effect of the present invention can be obtained, the above-mentioned configuration, method, and known technology can be appropriately applied. Hereinafter, the mode preferably applied to the present invention will be further described.

[0189] Next, in the metal negative electrode according to one embodiment of the present invention, the metal constituting the negative electrode active material is preferably selected from the group consisting of zinc, lithium, magnesium, sodium, potassium, and calcium, and alloys containing these metals in components. Group. Zinc, lithium, magnesium, sodium, potassium, and calcium are known as metals ...

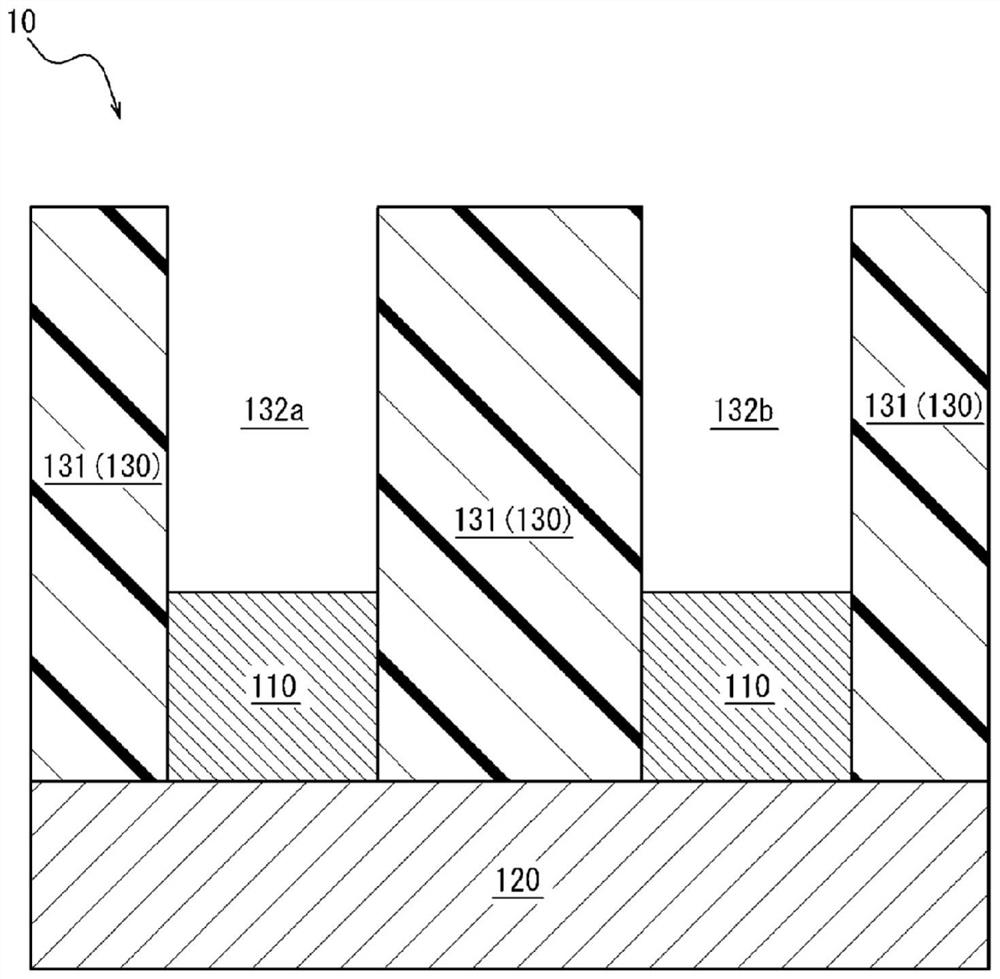

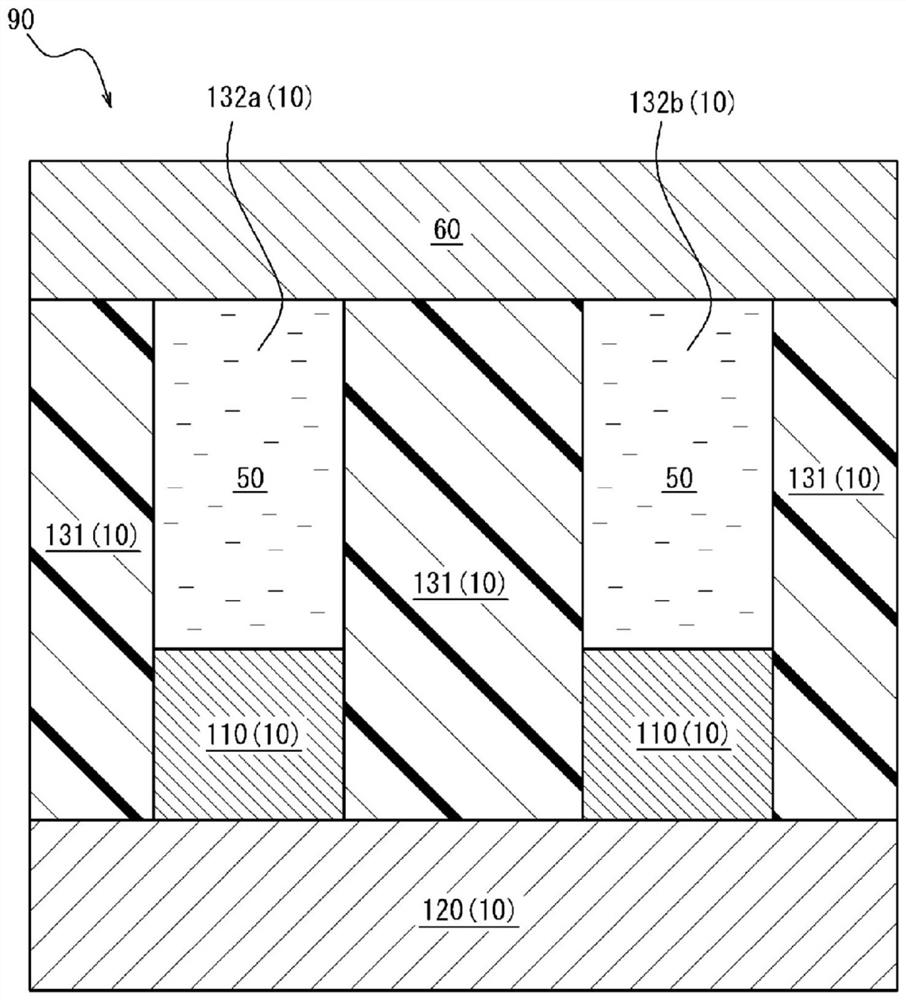

Embodiment 1

[0200] The zinc negative electrode in which the metal among the metal negative electrodes of the present invention is zinc was produced as follows. First, yes Figure 15 The copper plate shown (plating part: 30 mm x 40 mm x 0.2 mm, lead part: 5 mm x 50 mm x 0.2 mm) was subjected to pretreatment of polishing paper and oxalic acid etching, and then the plated part was covered with a commercially available masking material for plating. Masking is performed on one side and one side of the lead, and on both sides and sides of the lead part. Next, 1.2 mol / L of zinc sulfate heptahydrate, 0.56 mol / L of sodium sulfate, and 0.02 g / L of bone glue were dissolved in distilled water, and the pH was set to 2 to prepare a zinc plating bath. This zinc-plating bath was put into a beaker, and the above-mentioned copper plate and a platinum plate (50 mm×50 mm×0.1 mm) to which the platinum wire was attached as a lead were immersed in the zinc-plating bath so as to face each other at a distance of...

Embodiment 2

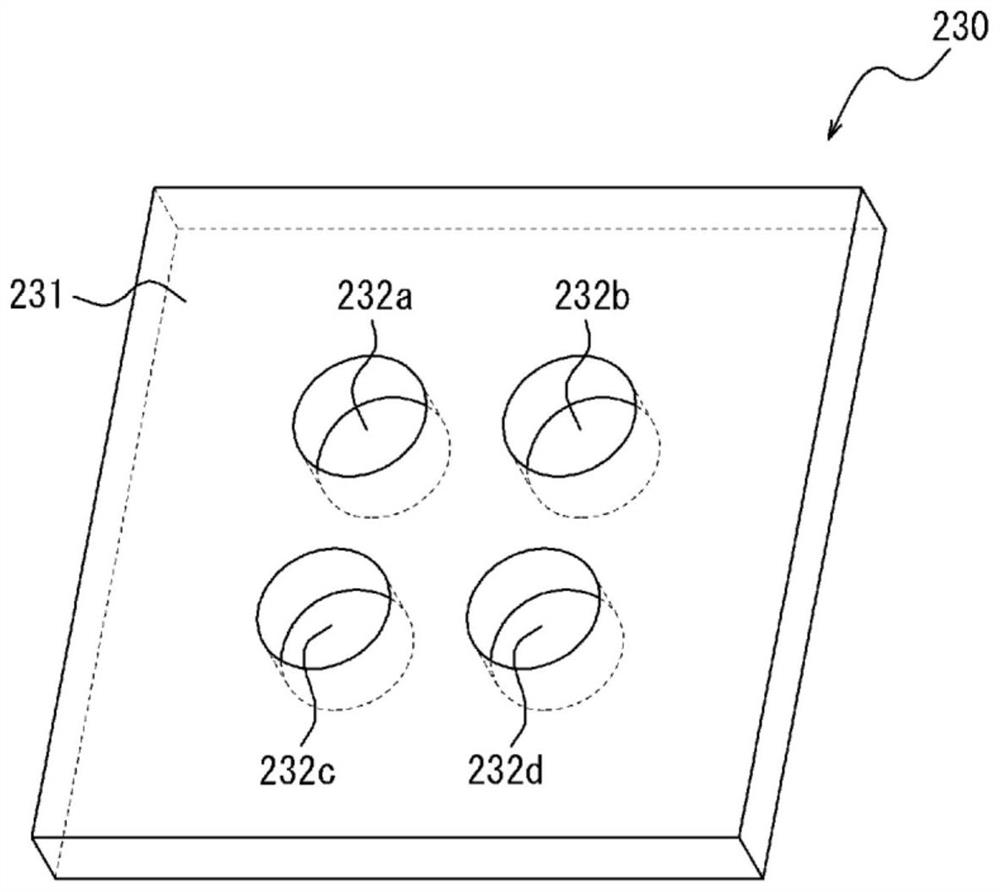

[0216] In the metal negative electrode of the present invention, a zinc negative electrode in which the metal of the active material portion is zinc was prepared as follows. First, using the same method and conditions as in Example 1, Figure 15 The copper plate shown is plated, in turn, as Figure 16 As shown, a circle with a diameter of 20 mm remained in the center of the galvanized single side, and a commercially available masking material was applied to the other part. Next, in the circle with a diameter of 20 mm, remove the Figure 32 A commercially available masking material was applied to the portions corresponding to the electrolyte holding portions in the reaction space limiting portion of the shown structure, that is, four circles with a diameter of 5 mm and a circle with a diameter of 4 mm arranged in the center thereof. Furthermore, on the surface on which the masking material is applied, it is adhered to Figure 32 The reaction space limiting portion made of ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com