Vinyl acetate catalyst and vinyl acetate synthesis method

A vinyl acetate, catalyst technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as low catalyst selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1. Catalyst preparation

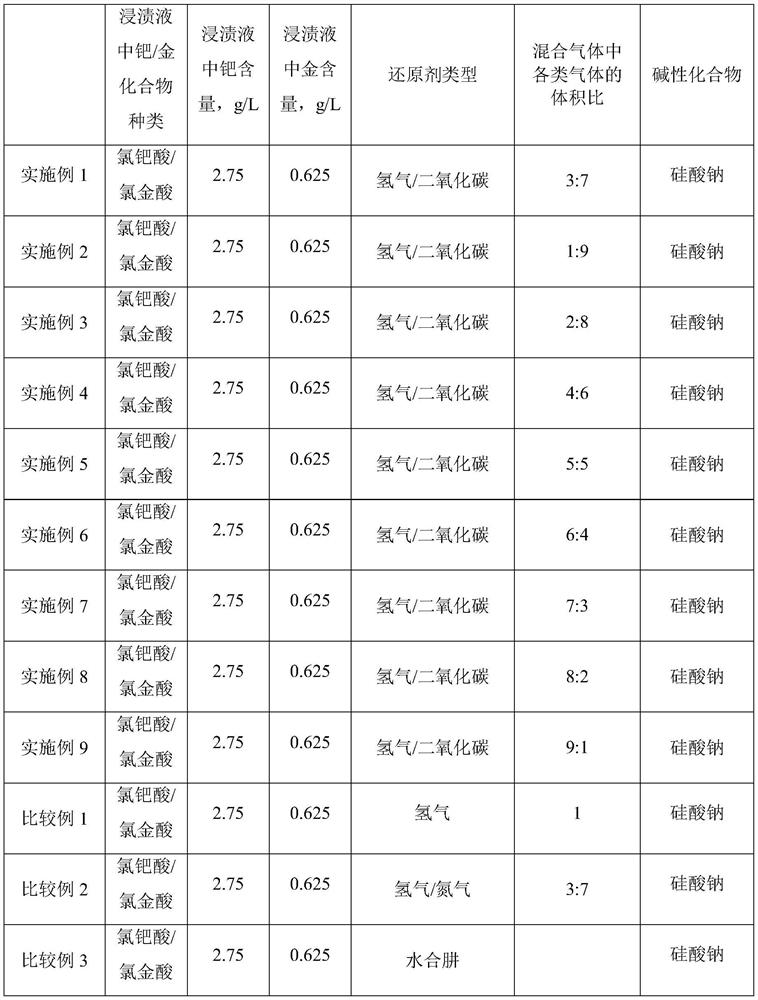

[0059] (a) Take 1100ml spherical silica carrier (diameter is 5mm, specific surface is 175m 2 / g, the pore volume is 0.8cm 3 / g) is immersed in chloropalladic acid, chloroauric acid mixed aqueous solution, calculates according to solid-liquid volume ratio is 1:1.2, wherein the content of palladium in the solution used is 2.75g / L, and the content of gold is 0.625g / L, gets Catalyst precursor I;

[0060] (b) Add 100ml sodium silicate aqueous solution (27.5g Na 2 SiO 3 9H 2 O is configured as 100ml aqueous solution), mixed uniformly and left to stand for 24 hours, then dried at 80°C for 8 hours to obtain catalyst precursor II;

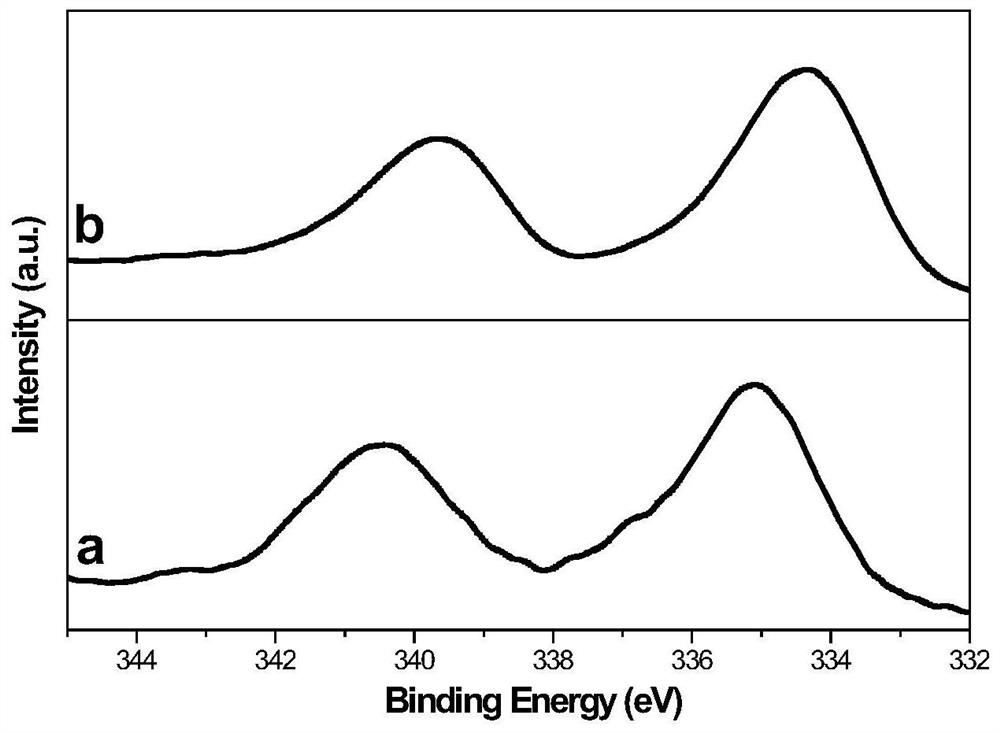

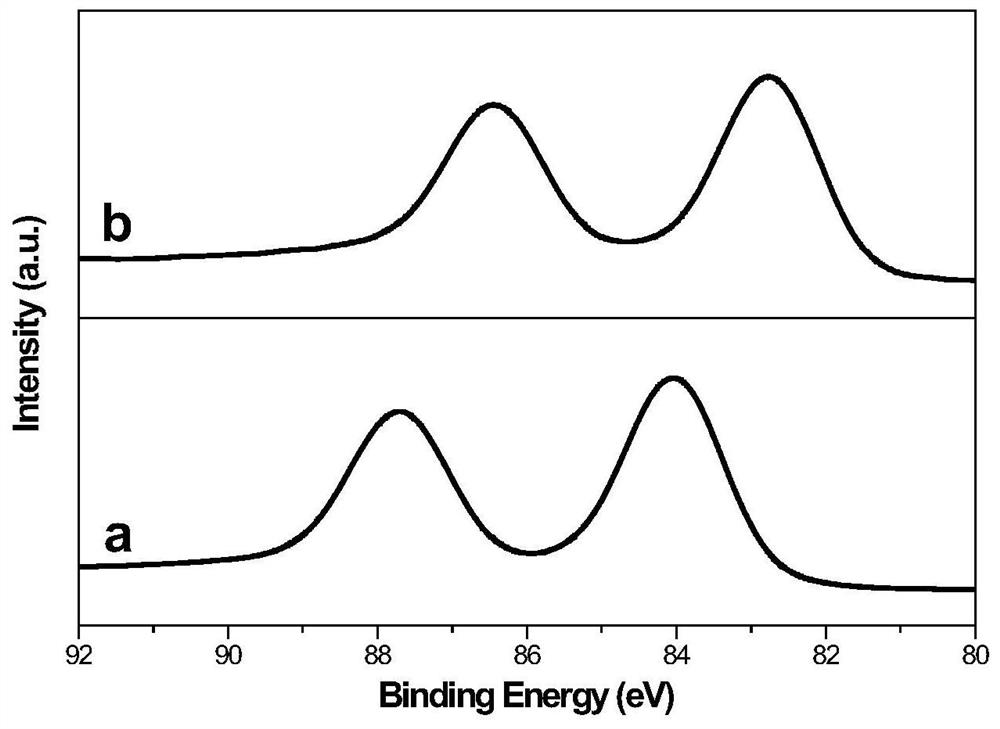

[0061] (c) The catalyst precursor II was reduced in a hydrogen / carbon dioxide atmosphere. The volume ratio of hydrogen to carbon dioxide is 3:7, the flow rate of the mixed gas is 0.2ml / min, the pressure is 0.5MPa, the reduction temperature is 200°C, and the reduction time is 3 hours to obtain the catalyst precursor III...

Embodiment 2

[0074] 1. Catalyst preparation

[0075] (a) Take 1100ml spherical silica carrier (diameter is 5mm, specific surface is 175m 2 / g, the pore volume is 0.8cm 3 / g) is immersed in chloropalladic acid, chloroauric acid mixed aqueous solution, calculates according to solid-liquid volume ratio is 1:1.2, wherein the content of palladium in the solution used is 2.75g / L, and the content of gold is 0.625g / L, gets Catalyst precursor I;

[0076] (b) Add 100ml sodium silicate aqueous solution (27.5g Na 2 SiO 3 9H 2 O is configured as 100ml aqueous solution), mixed uniformly and left to stand for 24 hours, then dried at 80°C for 8 hours to obtain catalyst precursor II;

[0077] (c) The catalyst precursor II was reduced in a hydrogen / carbon dioxide atmosphere. The volume ratio of hydrogen to carbon dioxide is 1:9, the flow rate of the mixed gas is 0.2ml / min, the pressure is 0.5MPa, the reduction temperature is 200°C, and the reduction time is 3 hours to obtain the catalyst precursor III...

Embodiment 3

[0083] 1. Catalyst preparation

[0084] (a) Take 1100ml spherical silica carrier (diameter is 5mm, specific surface is 175m 2 / g, the pore volume is 0.8cm 3 / g) is immersed in chloropalladic acid, chloroauric acid mixed aqueous solution, calculates according to solid-liquid volume ratio is 1:1.2, wherein the content of palladium in the solution used is 2.75g / L, and the content of gold is 0.625g / L, gets Catalyst precursor I;

[0085] (b) Add 100ml sodium silicate aqueous solution (27.5g Na 2 SiO 3 9H 2 O is configured as 100ml aqueous solution), mixed uniformly and left to stand for 24 hours, then dried at 80°C for 8 hours to obtain catalyst precursor II;

[0086] (c) The catalyst precursor II was reduced in a hydrogen / carbon dioxide atmosphere. The volume ratio of hydrogen to carbon dioxide is 2:8, the flow rate of the mixed gas is 0.2ml / min, the pressure is 0.5MPa, the reduction temperature is 200°C, and the reduction time is 3 hours to obtain the catalyst precursor III...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com