Hypercoagulated heavy oil wellbore lifting biological treatment method

A high-condensation oil well and biological treatment technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problem of not being able to effectively remove high-condensation oil wellbore processing methods that do not involve high-condensation heavy oil wellbore treatment Problems such as waxy components of heavy oil and the inability to lift high-condensation heavy oil have achieved the effects of good field test results, wide application range and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] General situation of high pouring heavy oil test well B15 of an oil production plant in Shengli Oilfield: Reservoir temperature is 86°C, formation water salinity is 49554mg / L, crude oil viscosity is 3412.5mPa.s, colloidal asphaltene content is 17.2%, wax content rate is 30.3% , comprehensive water content of 21%. Utilize the method of the present invention to improve this well shaft lifting efficiency, concrete steps are as follows:

[0055] 1. Screening of test wells

[0056] Reservoir temperature is 86°C, salinity of formation water is 49554mg / L, viscosity of crude oil is 3412.5mPa.s, colloidal asphaltene content is 17.2%, wax content is 30.3%, and comprehensive water content is 21%. The screening criteria of the test wells of the present invention are met, so the present invention can be practiced.

[0057] 2. Selection of microbial flora

[0058] Specific steps are as follows:

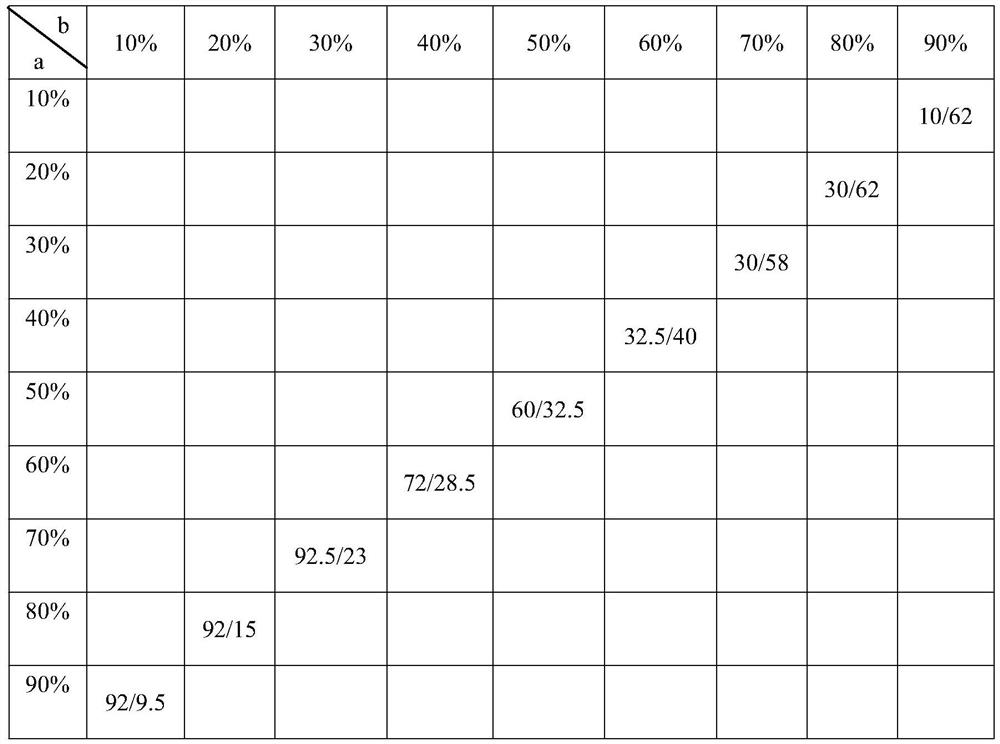

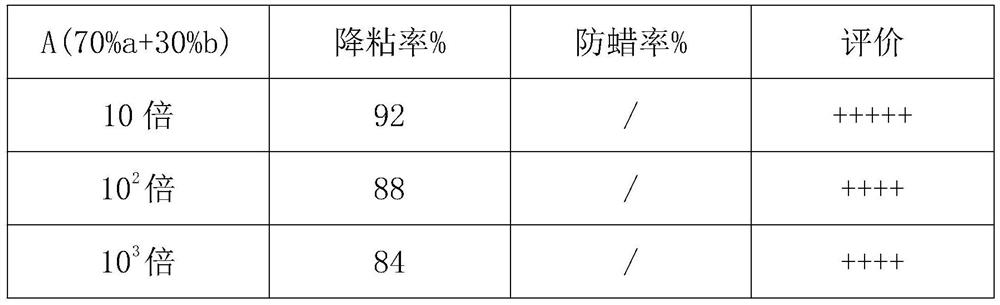

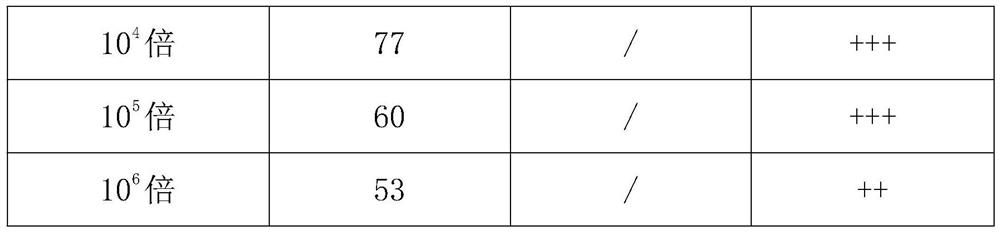

[0059] Mix 10%V / V~90%V / Vviscosity-reducing strain a (Bacillus subtilis) with 90%V / V~...

Embodiment 2

[0091] General situation of high pouring heavy oil test well B13 in an oil production plant in Shengli Oilfield: Reservoir temperature is 84°C, formation water salinity is 48794mg / L, crude oil viscosity is 3350.5mPa.s, colloidal asphaltene content is 16.2%, wax content rate is 29.3% , comprehensive water content of 25%. Utilize the method of the present invention to improve this well shaft lifting efficiency, concrete steps are as follows:

[0092] 1. Screening of test wells

[0093] Reservoir temperature is 84°C, salinity of formation water is 48794mg / L, viscosity of crude oil is 3350.5mPa.s, colloidal asphaltene content is 16.2%, wax content is 29.3%, and comprehensive water content is 25%. The screening criteria of the test wells of the present invention are met, so the present invention can be practiced.

[0094] 2. Selection of microbial flora

[0095] Specific steps are as follows:

[0096] Mix 10%V / V~90%V / Vviscosity-reducing strain a (Bacillus subtilis) with 90%V / V~...

Embodiment 3

[0128] General situation of high pouring heavy oil test well C15 in an oil production plant in Shengli Oilfield: Reservoir temperature is 80°C, formation water salinity is 46344mg / L, crude oil viscosity is 3222.5mPa.s, colloidal asphaltene content is 16.2%, wax content is 28.5% , comprehensive water content of 28%. Utilize the method of the present invention to improve this well shaft lifting efficiency, concrete steps are as follows:

[0129] 1. Screening of test wells

[0130] Reservoir temperature is 80°C, salinity of formation water is 46344mg / L, viscosity of crude oil is 3222.5mPa.s, colloidal asphaltene content is 16.2%, wax content is 28.5%, and comprehensive water content is 28%. The screening criteria of the test wells of the present invention are met, so the present invention can be practiced.

[0131] 2. Selection of microbial flora

[0132] Specific steps are as follows:

[0133] Mix 10%V / V~90%V / Vviscosity-reducing strain a (Bacillus subtilis) with 90%V / V~10%V / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com