Preparation method of high-adhesion analgesic hydrogel microneedle patch and microneedle patch

A technology of hydrogel and microneedle sticking, which is applied in the direction of microneedles, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., which can solve the problems of adhesion dependence, low drug bioavailability, and diseased parts. allergies etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

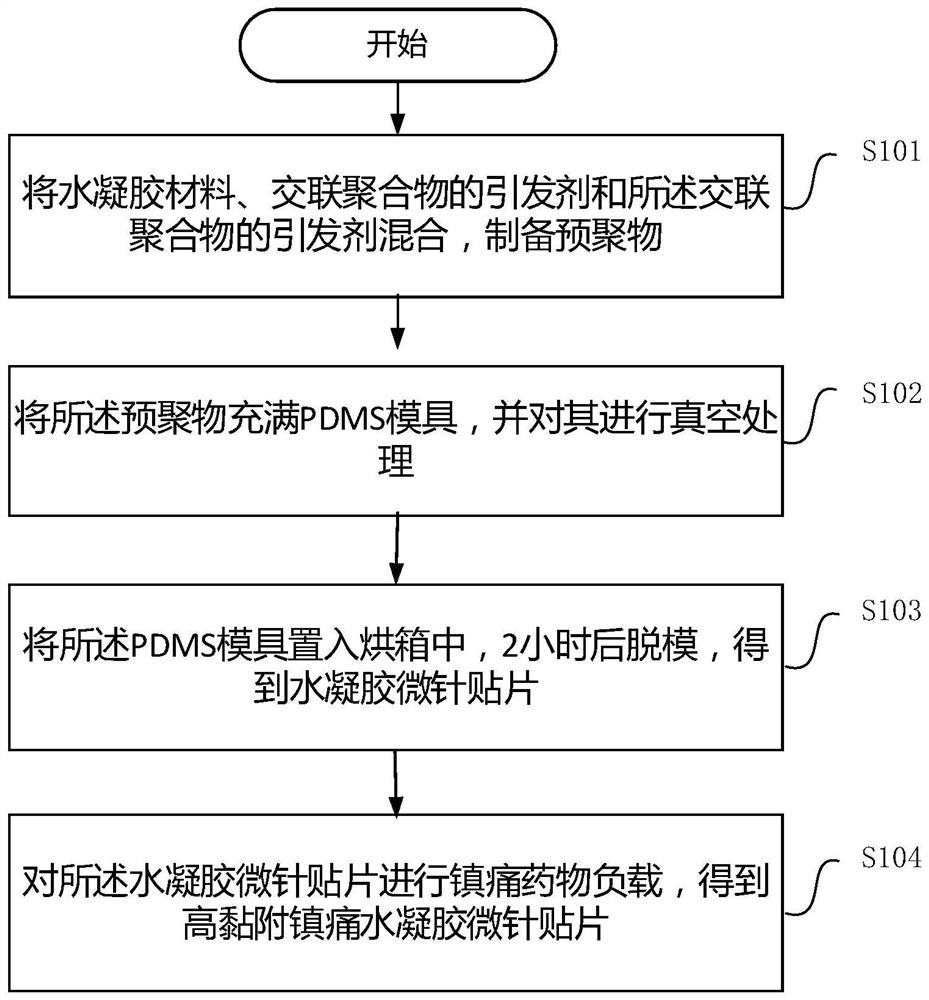

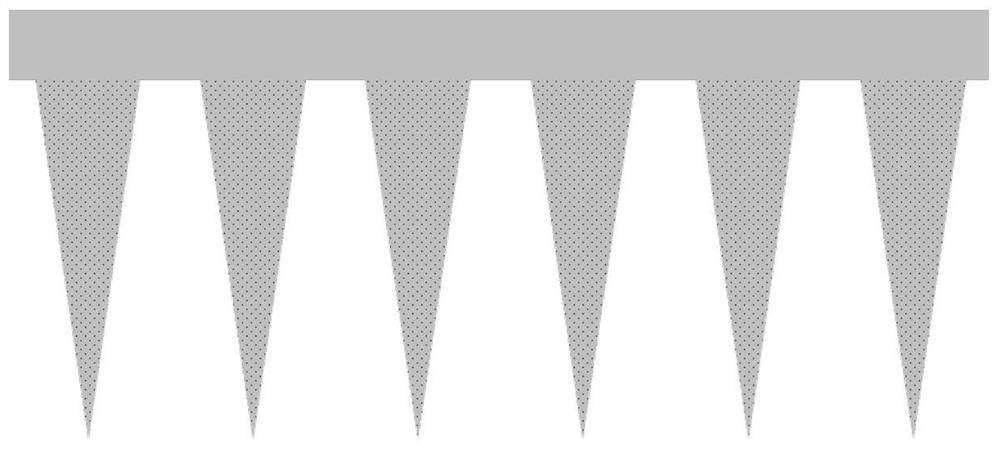

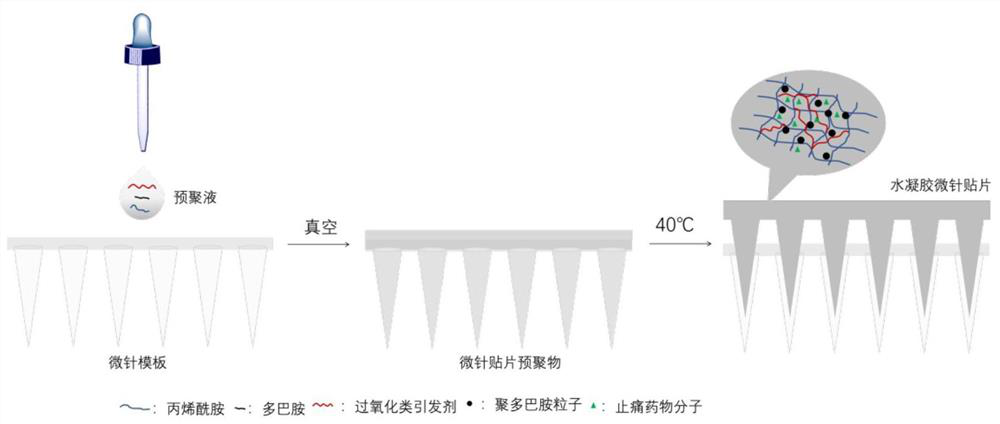

[0028] see figure 1 and image 3 , the present invention provides a method for preparing a highly adhesive analgesic hydrogel microneedle patch. Described preparation method comprises:

[0029] Step S101, mixing the hydrogel material, the initiator of the crosslinked polymer and the initiator of the crosslinked polymer to prepare a prepolymer.

[0030] Wherein, the hydrogel material is a cross-linked polymer of acrylamide and dopamine. Among them, acrylamide is used as a raw material for organic synthesis and as a raw material for polymer materials. Its polymers are usually soluble in water, especially for the flocculation of protein and starch in water. It has excellent properties such as flocculation, thickening, shear resistance, drag reduction, and dispersibility. Dopamine is a neurotransmitter, a chemical used to help cells send impulses. Polydopamine molecules are formed by the oxidative self-polymerization of dopamine molecules.

[0031] Preferably, the crosslink...

Embodiment 1

[0046] 1) 2 ml of acrylamide, 0.05 g of N,N-methylenebisacrylamide and 0.05 g of ammonium peroxide were uniformly mixed in ice water to form a prepolymer;

[0047] 2) After that, drop the above-mentioned mixed prepolymer into the prepared PDMS mold and carry out vacuum treatment to ensure that the prepolymer is completely filled with the mould;

[0048] 3) Transfer the above mold to an oven at 37°C, and remove the film after 2 hours to obtain a polydopamine-doped polyacrylamide hydrogel microneedle patch with high adhesion;

[0049] 4) Rinse the above-mentioned hydrogel microneedle patch with water for 3 times, cool to a ventilated place and wait for the liquid to evaporate gradually; then immerse the microneedle part of the hydrogel microneedle patch into 0.1 ml of 20% lidocaine hydrochloride Caine solution for 3 hours, take it out and cool it to a ventilated place until the drug gradually penetrates;

[0050] After repeated three times, the lidocaine-loaded polydopamine-dop...

Embodiment 2

[0052] 1) 2 milliliters of acrylamide, 0.02 gram of bupivacaine hydrochloride, 0.05 gram of N, N-methylenebisacrylamide and 0.05 gram of ammonium peroxide are uniformly mixed in ice water to form a prepolymer;

[0053] 2) Drop the above-mentioned prepolymer into the prepared PDMS mold and perform vacuum treatment on it to ensure that the prepolymer is completely filled with the mold;

[0054] 3) Transfer the above-mentioned mold to an oven at 37°C, remove the film after 2 hours, soak the obtained hydrogel patch repeatedly with ultrapure water to elute the bupivacaine molecules in the colloid, and obtain the bupivacaine-containing Molecularly imprinted highly adhesive polyacrylamide hydrogel microneedle patch;

[0055] 4) After rinsing the above-mentioned hydrogel microneedle patch with water for 3 times, use a pipette gun to pipette 0.1 ml of bupivacaine hydrochloride solution with a mass fraction of 20%, and evenly drop-coat it on the surface with bupivacaine molecular imprin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The maximum diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com