Precursor with hydroxide coated on outer layer of single crystal and preparation method of precursor

A hydroxide and precursor technology, which is applied in the field of precursors and preparations of hydroxides coated on the outer layer of single crystals, can solve the problems of reduced packing density, electronic short circuit, and reduced reversible capacity of ternary materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

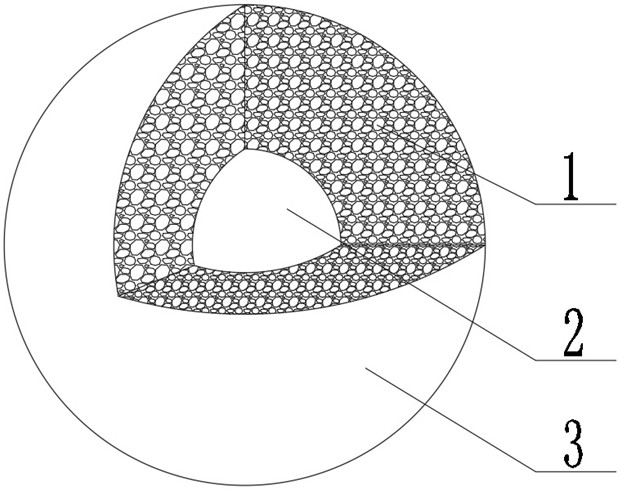

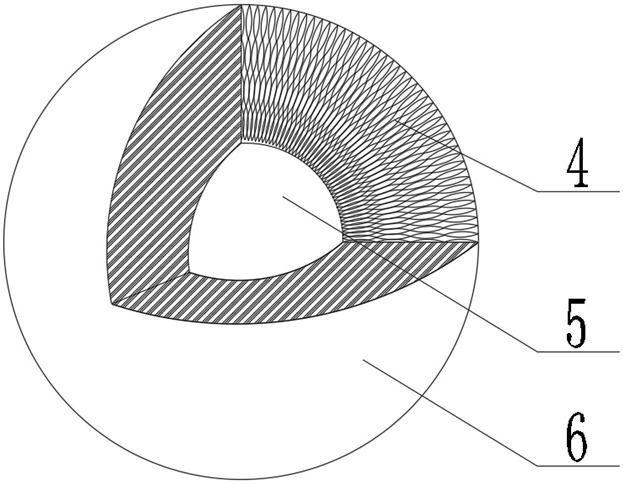

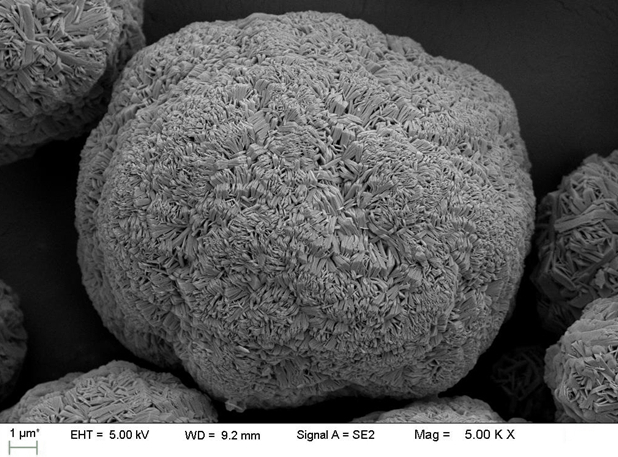

[0038] A precursor of a single crystal outer layer coated with hydroxide. The precursor is spherical or quasi-spherical particles by scanning electron microscopy, and the D50 is 9.0 μm by laser particle size analysis diffraction method; the particles are composed of inner core and outer shell Layer composition, the core of which is a single crystal cathode material, composed of the general formula LiNi 0.5 co 0.2 mn 0.3 o 2 It means that the diameter of the inner core is 2.0-4.0 μm; the shell layer of the particles is formed by the aggregation of nickel-containing composite hydroxide primary particles, and the primary particles are composed of the general formula Ni 0.5 co 0.2 mn 0.3 (OH) 2 Indicates that the primary particle morphology of the outer shell layer of the precursor is flake-like. Its preparation method is as follows:

[0039] Step 1, select the single crystal positive electrode material as the core according to the number of precursors required, and the sin...

Embodiment 2

[0051] A precursor of a single crystal outer layer coated with hydroxide. The precursor is spherical or quasi-spherical particles by scanning electron microscopy, and the D50 is 16.0 μm by laser particle size analysis diffraction method; Layer composition, the core of which is a single crystal cathode material, composed of the general formula LiNi 0.5 co 0.2 mn 0.3 o 2 It means that the diameter of the inner core is in the range of 2.0-5.0 μm; the shell layer of the particles is formed by the aggregation of nickel-containing composite hydroxide primary particles, and the primary particles are composed of the general formula Ni 0.5 co 0.2 mn 0.3 (OH) 2 Indicates that the primary particle morphology of the outer shell layer of the precursor is flake-like. Its preparation method is as follows:

[0052] Step 1, select the single crystal positive electrode material as the core according to the number of precursors required, and the single crystal positive electrode material ...

Embodiment 3

[0064] A precursor of a single crystal outer layer coated with hydroxide. The precursor is spherical or quasi-spherical particles measured by scanning electron microscopy, and the D50 is 12.0 μm measured by laser particle size analysis diffraction method; Layer composition, the core of which is a single crystal cathode material, composed of the general formula LiNi 0.5 co 0.2 mn 0.3 o 2 It means that the diameter of the inner core is in the range of 2.0-5.0 μm; the shell layer of the particles is formed by the aggregation of nickel-containing composite hydroxide primary particles, and the primary particles are composed of the general formula Ni 0.5 co 0.2 mn 0.3 (OH) 2 Indicates that the primary particle morphology of the outer shell layer of the precursor is flake-like. Its preparation method is as follows:

[0065] Step 1, select the single crystal positive electrode material as the core according to the number of precursors required, and the single crystal positive e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com