Semi-conductive EVA (Ethylene Vinyl Acetate) master batch for shielding and production mode thereof

A semi-conductive and masterbatch technology, which is applied in the field of semiconductive EVA masterbatch for shielding and its production method, can solve the problems of high price, low mechanical properties, and general shielding effectiveness, so as to improve electrical strength, increase service life, and prevent partial The effect of discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

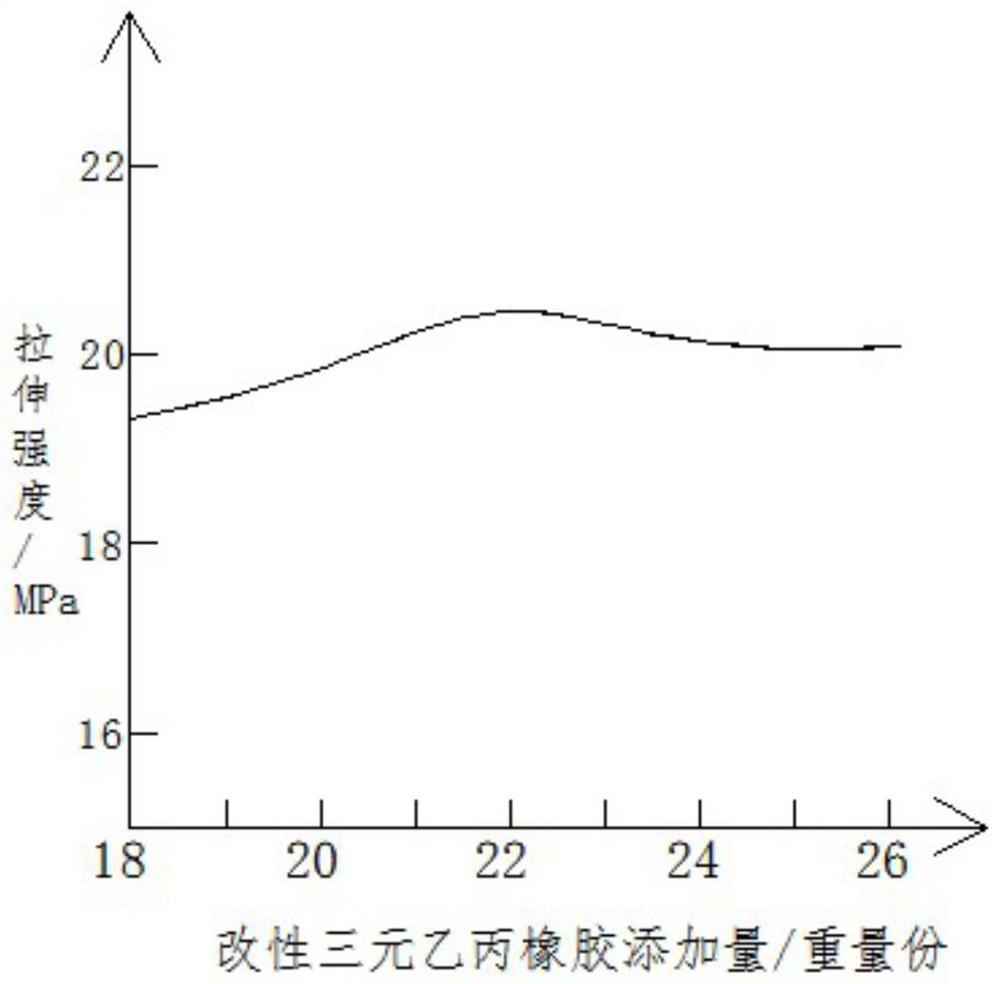

Method used

Image

Examples

preparation example Construction

[0061] A preparation method for shielding semiconductive EVA masterbatch, comprising the following steps:

[0062](1) Take by weight ethylene-vinyl acetate copolymer, conductive carbon black, modified EPDM rubber, zinc oxide, coupling agent, hydroxyapatite, dicumyl peroxide, chlorinated paraffin, Antioxidant, dispersant;

[0063] (2) Put ethylene-vinyl acetate copolymer, conductive carbon black, modified EPDM rubber, zinc oxide, coupling agent, hydroxyapatite, chlorinated paraffin, antioxidant, and dispersant in the dryer Carry out drying treatment, the drying temperature is 60°C, and the drying time is 1 hour to obtain dry materials;

[0064] (3) Add the dry material obtained above into a mixer to mix evenly, and then add it to a mixer for mixing to obtain a mixed material. The mixing temperature is 138° C. and the mixing time is 30 minutes;

[0065] (4) Add the mixed material and dicumyl peroxide to the internal mixer in sequence for internal mixing treatment, and then dis...

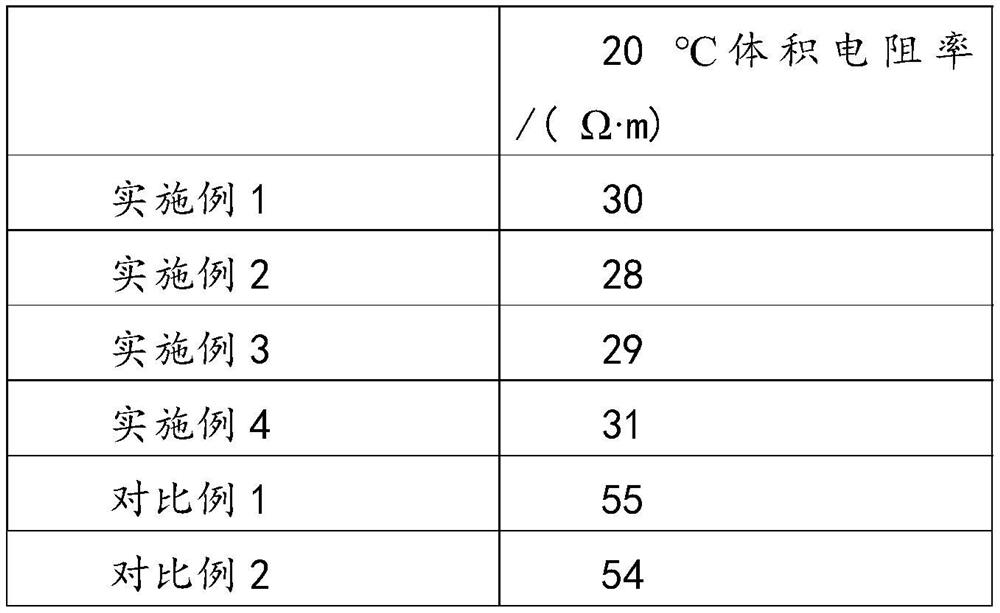

Embodiment 1

[0068] A semi-conductive EVA masterbatch for shielding, made of the following components in parts by weight: 70 parts of ethylene-vinyl acetate copolymer, 23 parts of conductive carbon black, 20 parts of modified EPDM rubber, 2 parts of zinc oxide, 1 part of coupling agent, 8 parts of hydroxyapatite, 1 part of dicumyl peroxide, 2 parts of chlorinated paraffin, 1.5 parts of antioxidant, 3 parts of dispersant.

[0069] The vinyl acetate content in the ethylene-vinyl acetate copolymer is 12%.

[0070] The preparation method of modified EPDM rubber is as follows:

[0071] (1) adding tetramethyl orthosilicate to the ethanol solution, stirring evenly to obtain a premix;

[0072] (2) Add graphene and kaolin successively to the mixer and carry out high-speed stirring and mixing to obtain a solid mixture;

[0073] (3) Add the fixed mixture obtained above to the premix, stir at a speed of 500r / min for 2 hours, and then perform ultrasonic dispersion treatment for 10min to obtain a disp...

Embodiment 2

[0095] A semi-conductive EVA masterbatch for shielding, made of the following components in parts by weight: 74 parts of ethylene-vinyl acetate copolymer, 24 parts of conductive carbon black, 22 parts of modified EPDM rubber, 3 parts of zinc oxide, 2 parts of coupling agent, 10 parts of hydroxyapatite, 1.5 parts of dicumyl peroxide, 3 parts of chlorinated paraffin, 2 parts of antioxidant, 4 parts of dispersant.

[0096] The vinyl acetate content in the ethylene-vinyl acetate copolymer is 12%.

[0097] The preparation method of modified EPDM rubber is as follows:

[0098] (1) adding tetramethyl orthosilicate to the ethanol solution, stirring evenly to obtain a premix;

[0099] (2) Add graphene and kaolin successively to the mixer and carry out high-speed stirring and mixing to obtain a solid mixture;

[0100] (3) Add the fixed mixture obtained above to the premix, stir at a speed of 500r / min for 2 hours, and then perform ultrasonic dispersion treatment for 10min to obtain a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com