Deep ultraviolet microscope imaging objective lens

An imaging objective lens and microscope technology, applied in the field of microscope imaging objective lens, can solve problems such as high cost and complicated manufacturing process, and achieve the effects of reducing manufacturing cost, simplifying structure, and reducing the number of sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The idea of this design is to use a combination of positive and negative lenses to eliminate spherical aberration and field curvature, and to use a symmetrical configuration in which the objective lens and the tube lens are separated on both sides of the pupil to improve the detection of coma, astigmatism, distortion, and lateral chromatic aberration. Poor elimination ability. Optical resolution formula, as shown in formula (1):

[0024] (1)

[0025] Among them, HP (Half Pitch) represents the half period, lambda represents the wavelength, and NA (Numerical Aperture) represents the numerical aperture. For example [Document 1]: lambda=248 nm, NA=0.9, then HP=69 nm. Another example is this design: lambda=193nm, NA=0.8, then HP=60 nm.

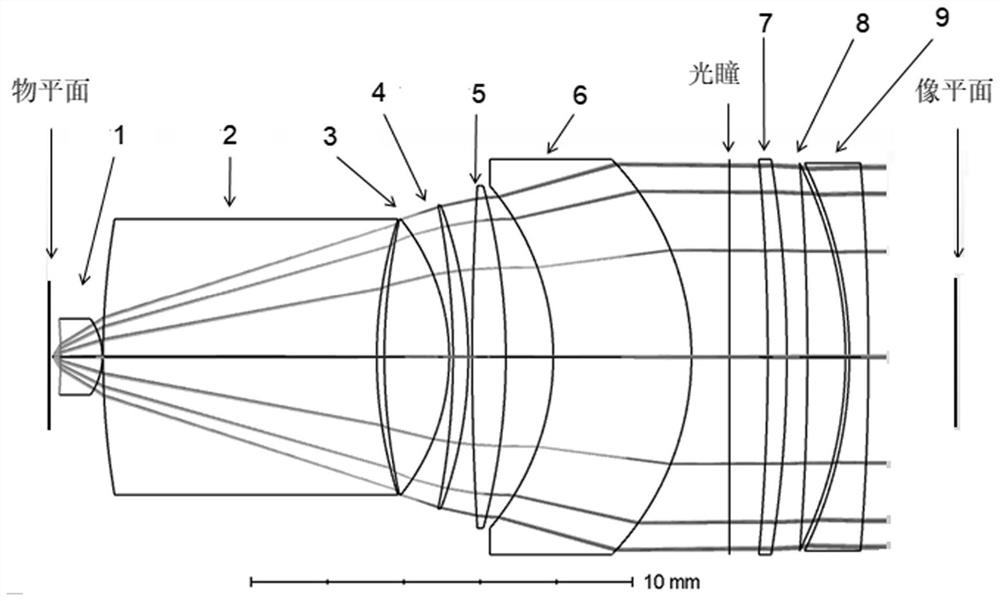

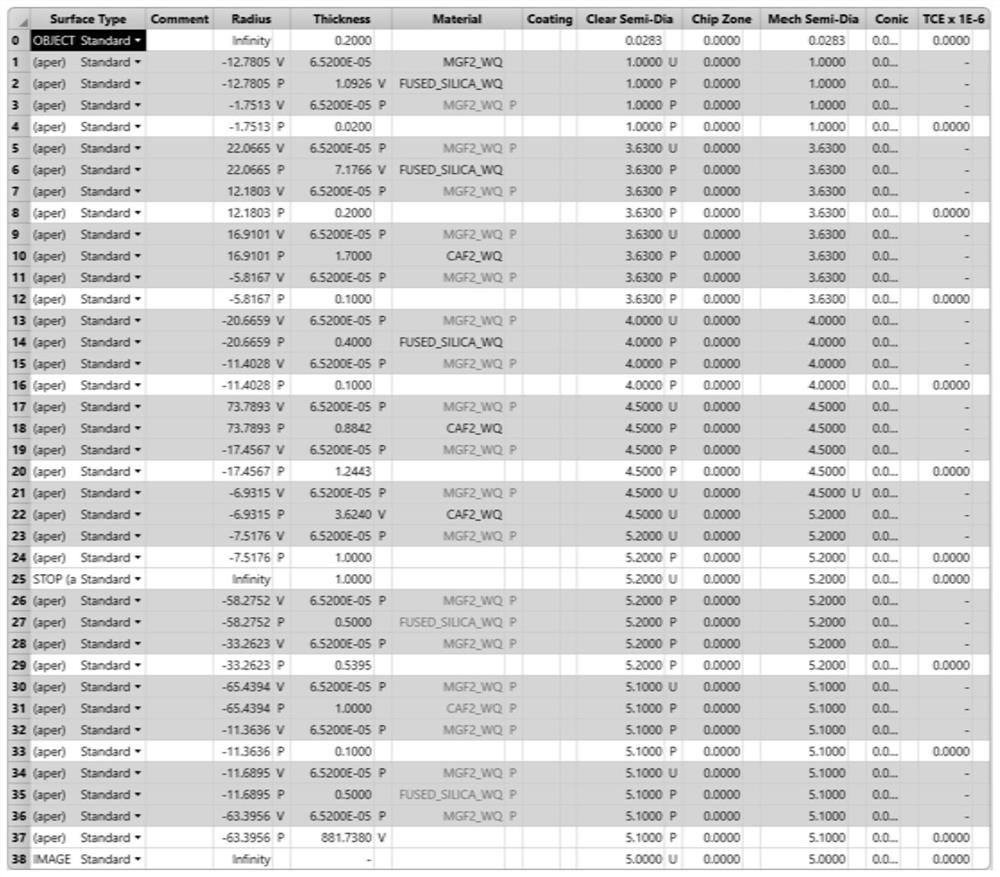

[0026] figure 1 It is a schematic diagram of the overall structure of an implementation of the objective lens of the present invention. The first lens 1, the second lens 2, the third lens 3, the fourth lens 4, the fifth lens 5 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com