Preparation method of nanometer beryllium oxide material

A technology of nano-beryllium oxide and beryllium hydroxide, which is applied in the field of preparation of nano-beryllium oxide materials, can solve problems such as cumbersome steps, environmental pollution, and large particle size, and achieve the effects of precise preparation process, avoiding particle aggregation, and low roasting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

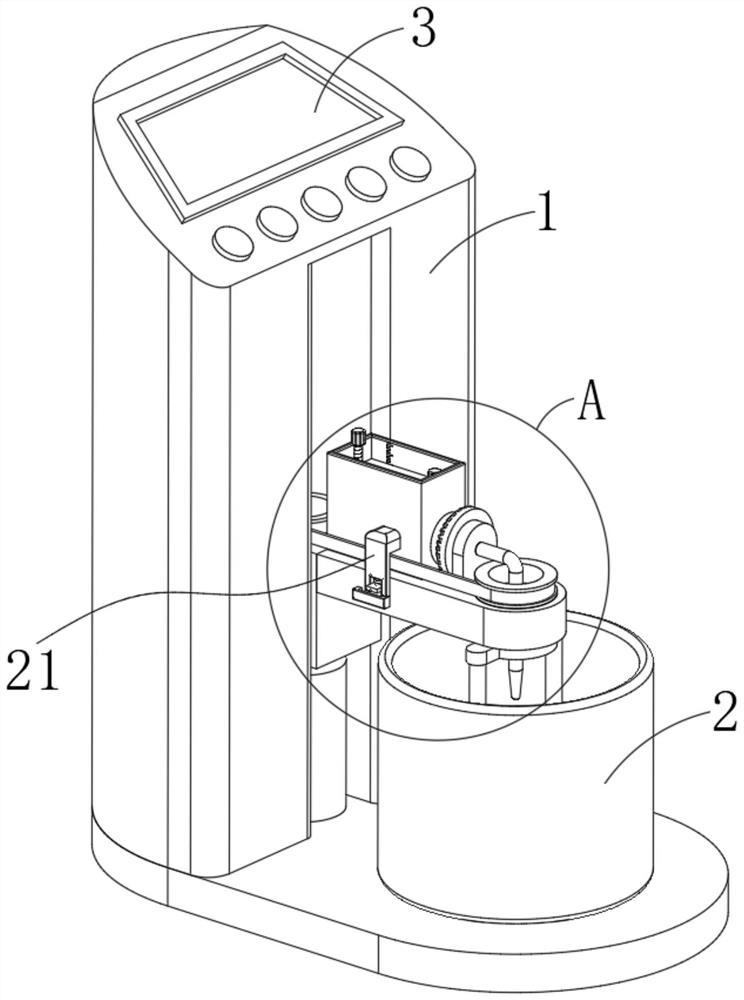

[0040] see Figure 1-Figure 16 , a method for preparing a nano-beryllium oxide material in the illustration, comprising the following steps:

[0041] S1. Preparation of beryllium sulfate solution and beryllium hydroxide suspension: Weigh analytically pure BeSO4 4H2O powder and dissolve it in deionized water to obtain a solution, keep stirring and add fatty amine, and strictly control the dropping rate to the final pH of the suspension 7.5 to 8.5, continue to stir for 30 to 60 minutes, and then leave the suspension to age for 12 hours;

[0042] S2. Preparation of beryllium hydroxide gel: Stir the suspension after standing still, filter with a vacuum filter funnel and fully filter and wash with deionized water to obtain a milky white gel;

[0043] S3. Hydrothermal pretreatment of beryllium hydroxide gel: redissolve the gel in deionized water and add polyvinylpyrrolidone and ammonium persulfate in proportion, stir evenly at a certain temperature and sonicate for 30min, transfer ...

Embodiment 2

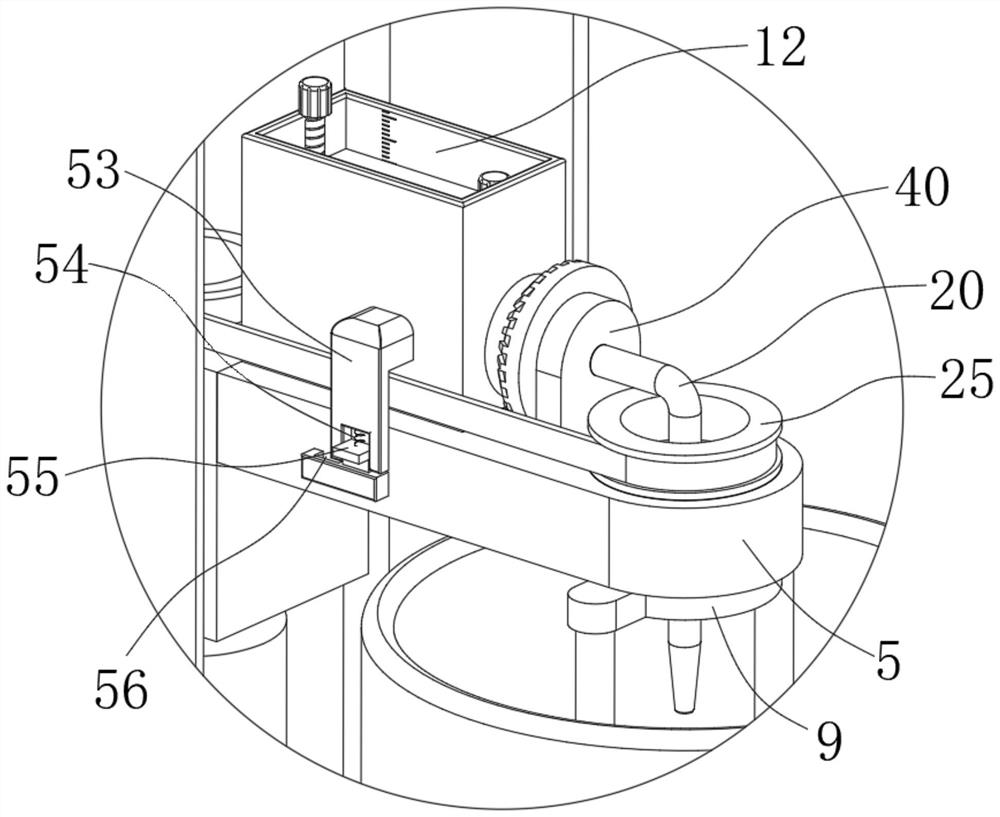

[0054] see Figure 4 Illustrate embodiment 2, present embodiment is further described to embodiment 1, and stirring device 6 in the figure comprises the rotating tube 9 that is connected with support rod 5 rotations, and is fixedly connected with stirring bar 10 and pH value tester on rotating tube 9 11.

[0055] see Figure 1-Figure 2 and Figure 5-Figure 6 , the dripping device 7 in the illustration includes a storage box 12 for storing fatty amine, the first push plate 13 is slidably connected in the storage box 12, and the top of the first push plate 13 is slidably connected with the storage box 12 inner walls. The second push plate 14 of the storage box 12 is slidably connected with an adjustment plate 15, the top of the second push plate 14 is fixedly connected with a limit block 16 that is slidably connected with the adjustment plate 15, and the storage box 12 is rotatably connected with an adjustment plate. 15 threaded adjustment screw rod 17, the storage box 12 is ...

Embodiment 3

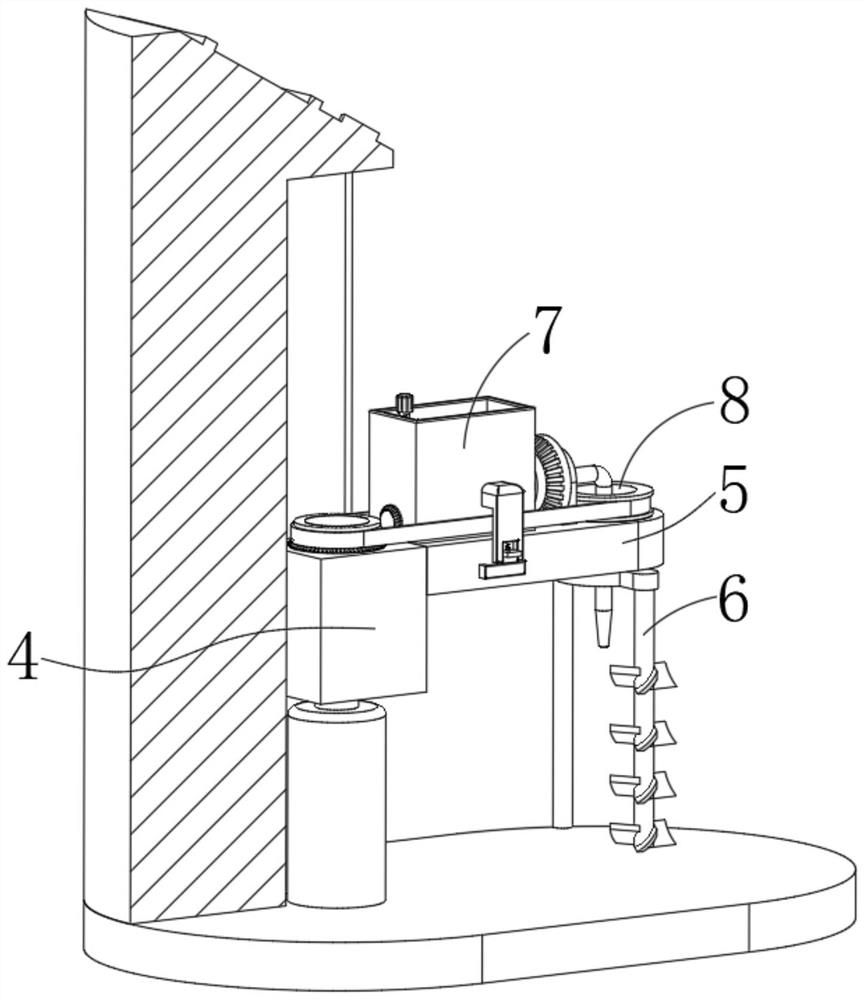

[0059] see Figure 7-Figure 10 Embodiment 3 is described. This embodiment further describes Embodiment 1. The switching device 27 in the illustration includes a driving disc 28 coaxially fixedly connected to the bottom surface of the driving wheel 24. There are multiple groups of first slide grooves provided on the rotating tube 9. 29, the first chute 29 is slidingly connected with a tooth block 30, the first chute 29 is fixedly connected with the first spring 31 fixedly connected with the tooth block 30, the tooth block 30 is fixedly connected with the limit column 32, and the drive plate 28 There is an arc-shaped groove 33 slidingly connected with the limit column 32 on the top, and the first gear 34 meshed with the tooth block 30 is connected to the support rod 5 in rotation. A linkage 35 that promotes fatty amines for intermittent dripping.

[0060] see Figure 7-Figure 11 , the linkage 35 in the illustration includes a first bevel gear 36 coaxially fixedly connected wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com