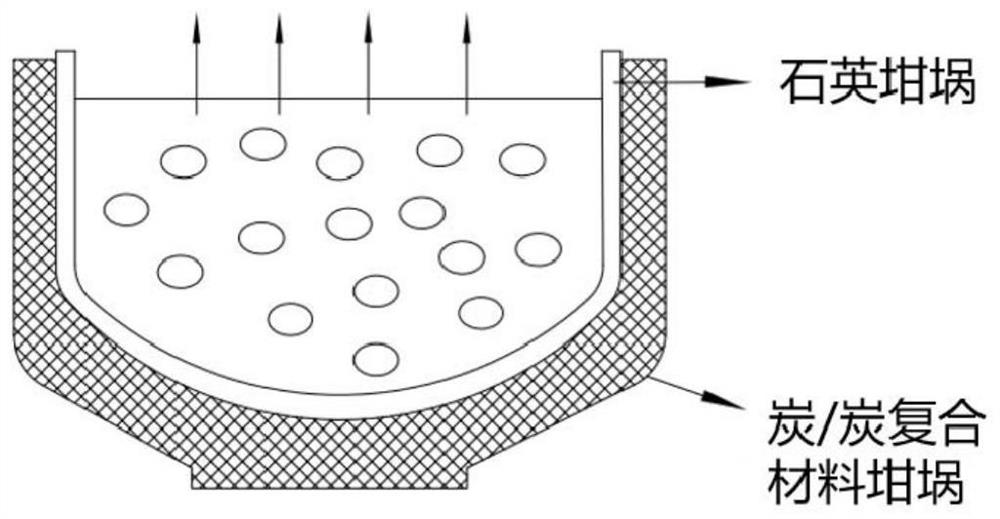

Carbon/carbon composite material crucible containing aluminum oxide coating and silicon carbide coating

A technology of carbon composite materials and silicon carbide coatings, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and crystal growth, can solve the problems of reducing the service life of crucibles, shortening the service life of crucibles, and complicated processes, and achieves guaranteed Effects of bonding strength, improving service life, and improving hoop tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

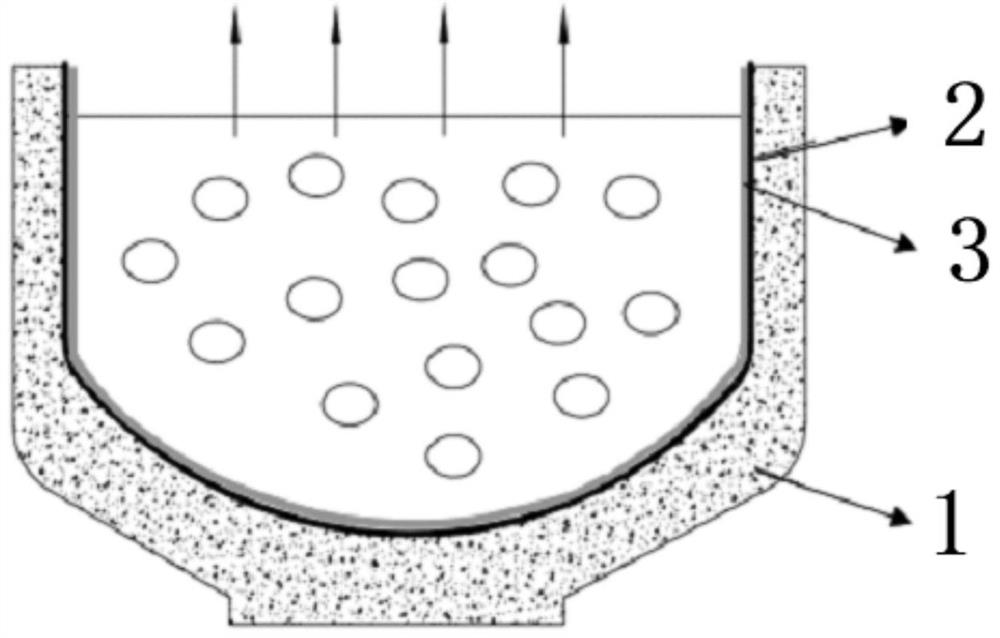

[0031] The preparation steps of a carbon / carbon composite material crucible containing alumina coating and silicon carbide coating are as follows:

[0032] (1) The bulk density is 0.30g / cm3 prepared in the form of axial carbon fiber non-weft cloth / carbon mesh tire composite layup and circumferential carbon fiber continuous winding layer alternately stacked and needled 3 carbon fiber prefabricated body;

[0033] Among them, the carbon fiber non-weft cloth / carbon mesh tire composite layer contains a layer of carbon fiber non-weft cloth and a layer of carbon mesh tire, and the carbon fiber non-weft cloth / carbon mesh tire composite layer and a layer of carbon fiber continuous winding layer Alternate superposition;

[0034] (2) First, the carbon fiber preform is subjected to pyrolytic carbon densification treatment by chemical vapor infiltration process and densified to 1.0g / cm 3, and then use the resin impregnation carbonization treatment process to continue to densify and densi...

Embodiment 2

[0043] The preparation steps of a carbon / carbon composite material crucible containing alumina coating and silicon carbide coating are as follows:

[0044] (1) The bulk density is 0.60g / cm3 prepared in the form of axial carbon fiber non-weft cloth / carbon mesh tire composite layup and circumferential carbon fiber continuous winding layer alternately stacked and needle punched 3 carbon fiber prefabricated body;

[0045] Among them, the carbon fiber non-weft cloth / carbon mesh tire composite layer contains a layer of carbon fiber non-weft cloth and a layer of carbon mesh tire, and the carbon fiber non-weft cloth / carbon mesh tire composite layer and a layer of carbon fiber continuous winding layer Alternate superposition;

[0046] (2) First, the carbon fiber preform is subjected to pyrolytic carbon densification treatment by chemical vapor infiltration process and densified to 1.2g / cm 3 , and then use the resin impregnation carbonization treatment process to continue to densify a...

Embodiment 3

[0055] The preparation steps of a carbon / carbon composite material crucible containing alumina coating and silicon carbide coating are as follows:

[0056] (1) The bulk density is 0.40g / cm3 prepared in the form of axial carbon fiber non-weft cloth / carbon mesh tire composite layup and circumferential carbon fiber continuous winding layer alternately stacked and needle punched 3 carbon fiber prefabricated body;

[0057] Among them, the carbon fiber non-weft cloth / carbon mesh tire composite layer contains a layer of carbon fiber non-weft cloth and a layer of carbon mesh tire, and the carbon fiber non-weft cloth / carbon mesh tire composite layer and a layer of carbon fiber continuous winding layer Alternate superposition;

[0058] (2) The carbon fiber preform is subjected to pyrolytic carbon densification treatment by chemical vapor infiltration process, and then mechanically processed to obtain a bulk density of 1.50g / cm 3 The carbon / carbon composite material crucible body 1;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com