Method for preparing polyvinylcarbazole/carbon dot composite material based on vinyl carbazole polymerization initiated by carbon dot/amine redox

A polyvinyl carbazole and vinyl carbazole technology, applied in the field of preparation of functional polymer materials, can solve the problems of harsh preparation process and high cost, and achieve rich functional groups, high nitrogen content, high photoelectric conversion efficiency and charge transfer rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

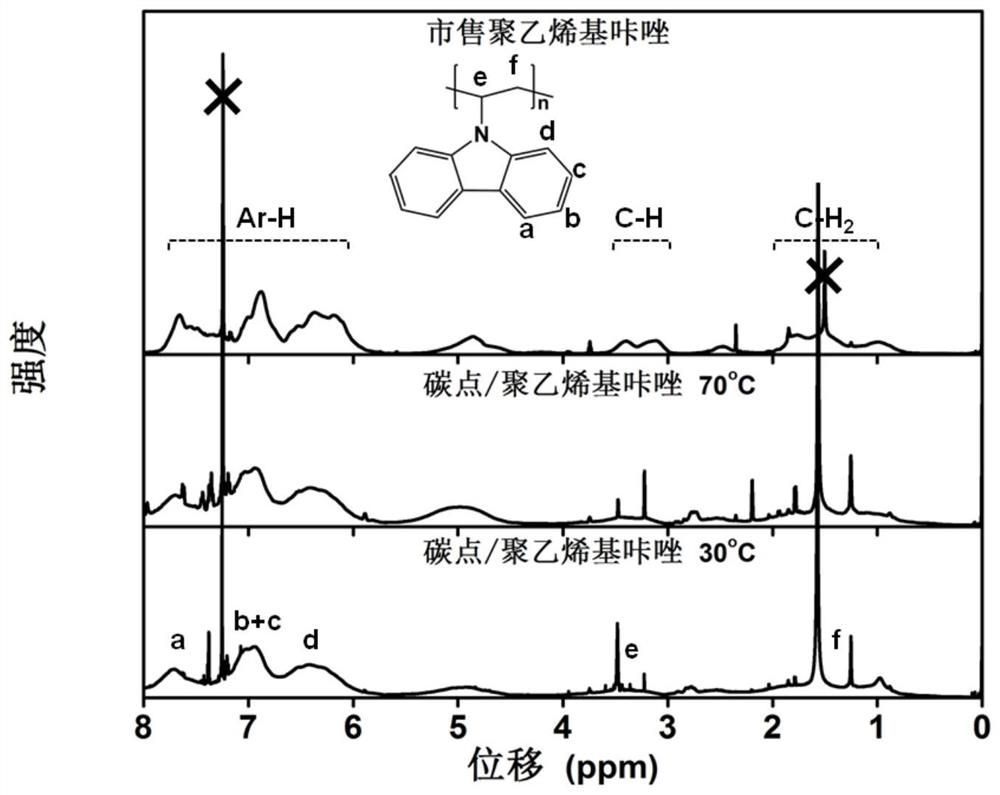

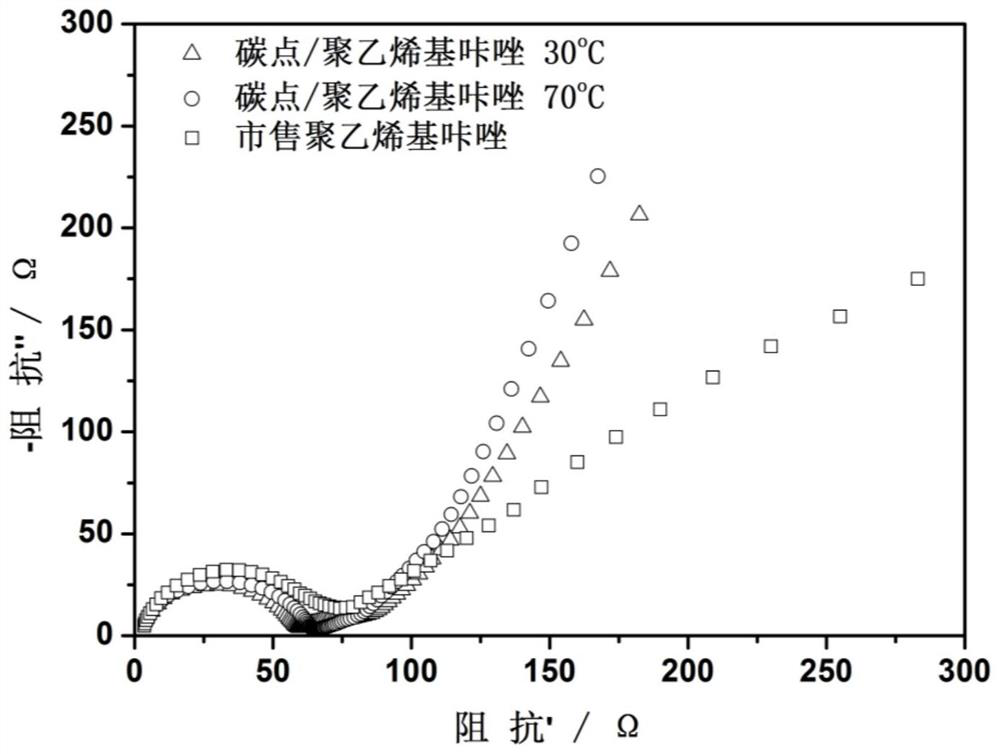

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing polyvinylcarbazole / carbon dot composite materials based on carbon dot / amine redox initiated vinyl carbazole polymerization, the steps are:

[0026] a. Mix 2 parts by mass of phenanthrene, 80 parts by mass of concentrated sulfuric acid, and 120 parts by mass of concentrated nitric acid, and react in a three-necked bottle equipped with a condensing device at a temperature of 80°C for 48 hours, then cool, filter, and deionized water Wash to obtain nitrophenanthrene;

[0027] b. Mix 0.1 parts by mass of nitrophenanthrene and 30 parts by mass of toluene, ultrasonically treat it for 30 minutes, then add it to a hydrothermal kettle containing a Teflon liner and raise the temperature to 200°C for 12 hours. After cooling, filter and dry , to get carbon dots;

[0028] c. Dissolving 0.02 parts by mass of aniline in 5 parts by mass of tetrahydrofuran to obtain solution A, and dispersing 0.08 parts by mass of carbon dots into 5 parts by mass of tetrahydrofura...

Embodiment 2

[0030] A method for preparing polyvinylcarbazole / carbon dot composite materials based on carbon dot / amine redox initiated vinyl carbazole polymerization, the steps are:

[0031] a. Mix 5 parts by mass of anthracene, 150 parts by mass of concentrated sulfuric acid, and 150 parts by mass of concentrated nitric acid, and react in a three-necked bottle equipped with a condensing device at a temperature of 80°C for 48 hours, then cool, filter, and deionized water Washing to obtain nitroanthracene;

[0032] b. Mix 0.3 parts by mass of nitroanthracene and 30 parts by mass of toluene, ultrasonically treat it for 30 minutes, then add it to a hydrothermal kettle containing a Teflon liner and raise the temperature to 200°C for 12 hours. After cooling, filter and dry get carbon dots;

[0033] c. Dissolving 0.1 parts by mass of m-phenylenediamine in 5 parts by mass of chlorobenzene to obtain solution A, and dispersing 0.1 parts by mass of carbon dots into 5 parts by mass of chlorobenzene ...

Embodiment 3

[0035] A method for preparing polyvinylcarbazole / carbon dot composite materials based on carbon dot / amine redox initiated vinyl carbazole polymerization, the steps are:

[0036]a. Mix 2 parts by mass of pyrene, 40 parts by mass of concentrated sulfuric acid, and 120 parts by mass of concentrated nitric acid, and react for 48 hours at a temperature of 80°C in a three-necked bottle equipped with a condensing device, then cool, filter, and deionize the water Wash to obtain nitropyrene;

[0037] b. Mix 0.4 parts by mass of nitropyrene and 30 parts by mass of toluene, ultrasonically treat it for 30 minutes, then add it to a hydrothermal kettle containing a Teflon liner and heat it up to 200°C for 12 hours. After cooling, filter and dry get carbon dots;

[0038] c. Dissolving 0.05 parts by mass of o-phenylenediamine in 5 parts by mass of toluene to obtain solution A, and dispersing 0.1 parts by mass of carbon dots into 5 parts by mass of toluene to obtain solution B. Dissolve 1 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com