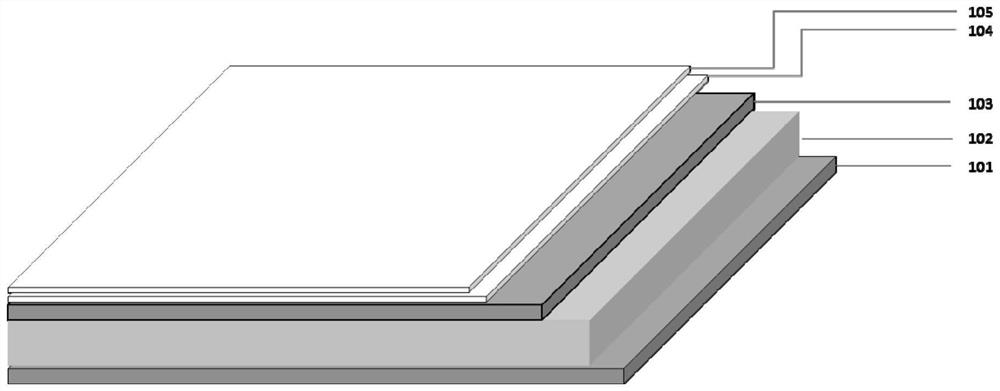

Surface-coated roof type packaging paper and production process thereof

A surface-coating and roof-type technology, applied in the field of papermaking, can solve the problems of difficult printing of exquisite patterns, poor visual experience, and lower sensory levels, etc., to achieve good economic and environmental benefits, high degree of closed cycle, pH value Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

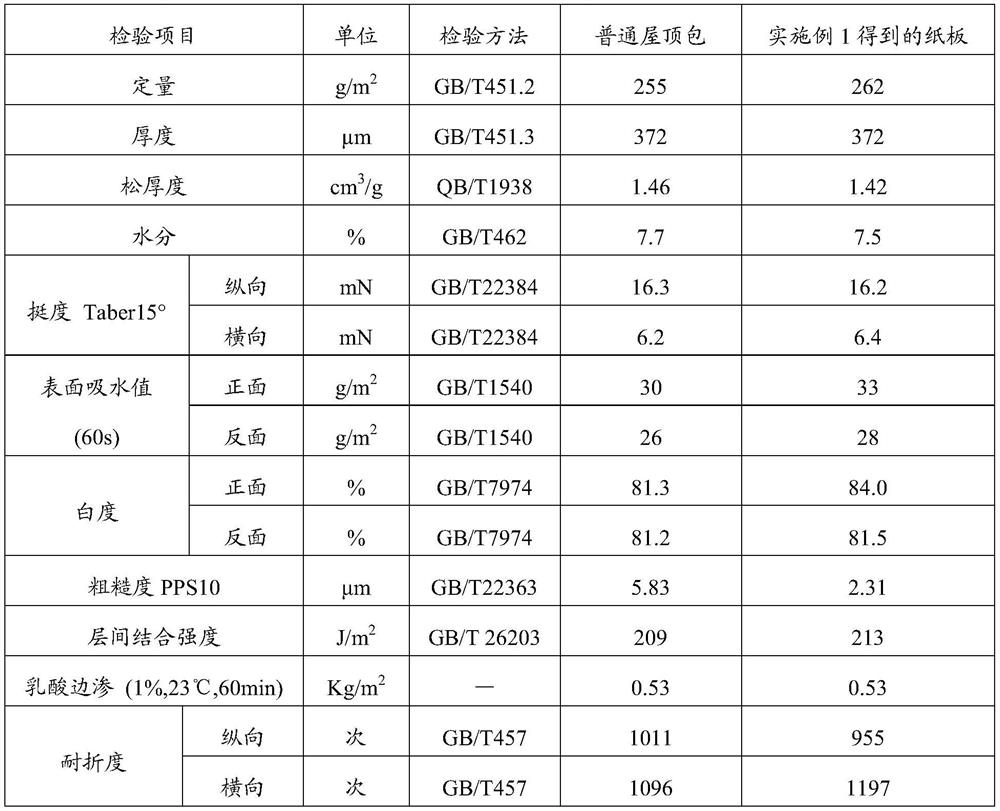

Embodiment 1

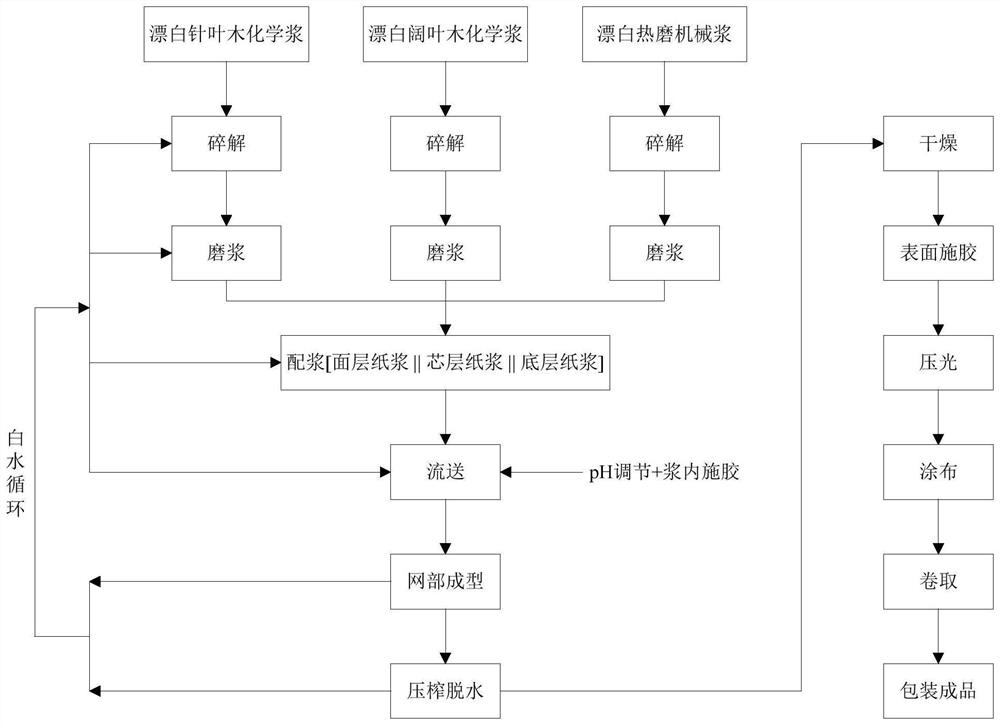

[0061] according to figure 2 The process flow shown prepares roof-top packaging paper, and the specific process is as follows:

[0062] Add bleached coniferous wood chemical pulp into the pulper, the pulp concentration is 5.5wt%, and pump it to the unloading tower after disintegration, and then pump it to the double disc refiner for refining treatment through the knocking pool; Leaf wood chemical pulp, pulp concentration 5.2wt%, pumped to the unloading tower after disintegration, and then pumped to the double disc refiner for refining treatment through the knocking pool; bleached thermomechanical pulp was added to the pulper, pulp concentration 5.3 wt%, crushed and pumped to the unloading tower, and then pumped to the double disc mill through the knocking pool for refining treatment.

[0063]The pulp after the disc grinding treatment is mixed according to the technical requirements to obtain the surface layer pulp, the core layer pulp and the bottom layer pulp respectively. ...

Embodiment 2

[0072] according to figure 2 The process flow shown prepares roof-top packaging paper, and the specific process is as follows:

[0073] Add bleached coniferous wood chemical pulp into the pulper, the pulp concentration is 5.5wt%, and pump it to the unloading tower after disintegration, and then pump it to the double disc refiner for refining treatment through the knocking pool; Leaf wood chemical pulp, with a pulp concentration of 5.3wt%, is crushed and pumped to the unloading tower, and then pumped to the double disc refiner for refining treatment through the knocking pool; bleached thermomechanical pulp is added to the pulper, and the pulp concentration is 5.2 wt%, crushed and pumped to the unloading tower, and then pumped to the double disc mill through the knocking pool for refining treatment.

[0074] The pulp after the disc grinding treatment is mixed according to the technical requirements to obtain the surface layer pulp, the core layer pulp and the bottom layer pulp...

Embodiment 3

[0083] according to figure 2 The process flow shown prepares roof-top packaging paper, and the specific process is as follows:

[0084] Add bleached coniferous wood chemical pulp into the pulper, the pulp concentration is 5.4wt%, and pump it to the unloading tower after disintegration, and then pump it to the double disc refiner for refining treatment through the knocking pool; Leaf wood chemical pulp with a pulp concentration of 5.4wt%, which is pumped to the unloading tower after crushing, and then pumped to the double disc refiner for refining treatment through the knocking pool; bleached thermomechanical pulp is added to the pulper with a pulp concentration of 5.1 wt%, crushed and pumped to the unloading tower, and then pumped to the double disc mill through the knocking pool for refining treatment.

[0085] The pulp after the disc grinding treatment is mixed according to the technical requirements to obtain the surface layer pulp, the core layer pulp and the bottom laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com