Lithium ion battery positive pole piece with safety coating and preparation method of lithium ion battery positive pole piece

A technology for lithium ion batteries and positive electrode pieces, applied in the field of electrochemistry, can solve the problems of large lower limit of coating thickness, increase of CPK, deterioration of electrical properties, etc., and achieve the effect of reducing production cost, production cycle and equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

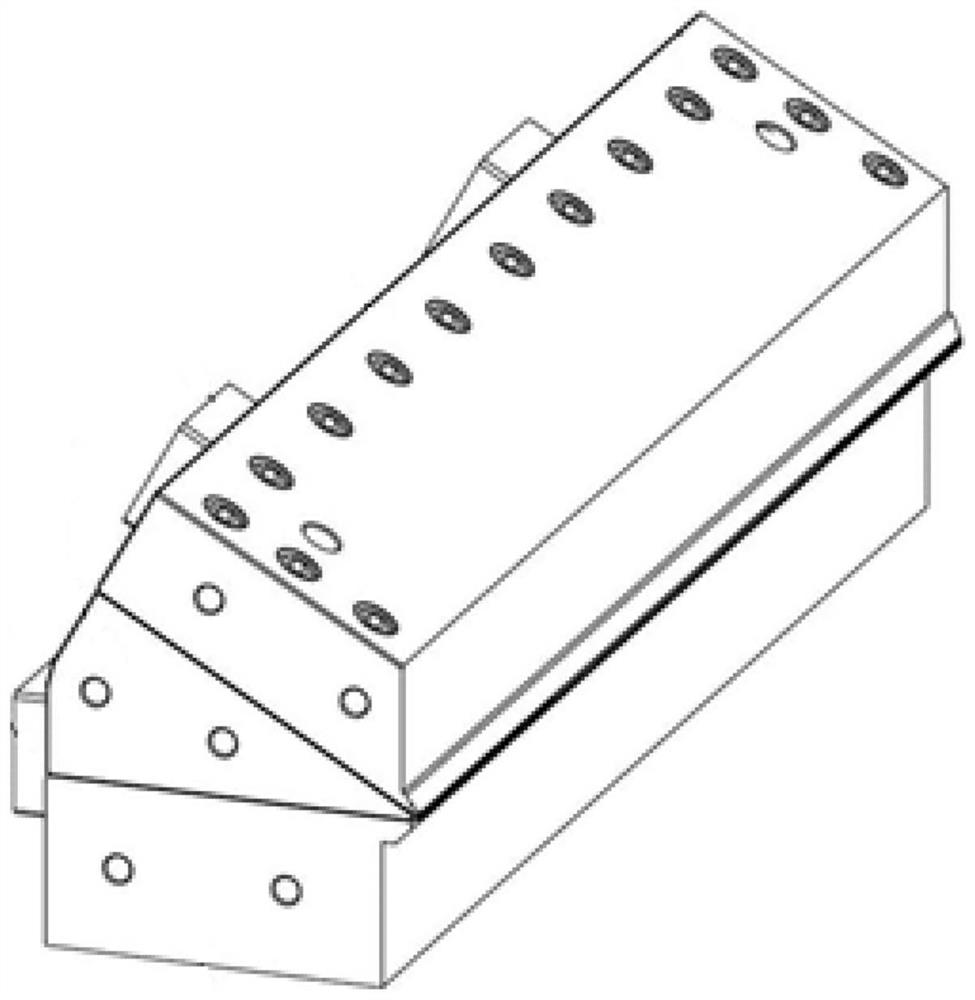

Image

Examples

preparation example Construction

[0039] A preparation method of a lithium-ion battery positive electrode sheet with a safety coating, the method comprising the following steps:

[0040] Preparation of safety coating slurry: add base material airgel material, high stability positive electrode material, conductive agent and binder into dispersant, and disperse to obtain safety coating slurry;

[0041] Typical preparation process: silica airgel 20wt%, lithium iron phosphate 75wt%, carbon black 2wt%, polyvinylidene fluoride 3wt%, dispersant is NMP, slurry solid content 10wt%, stirring in a high-speed mixer for 4h , to obtain a safety coating slurry with a viscosity of 5000cp.

[0042] Preparation of positive electrode active material slurry: After mixing and stirring the raw materials of the positive electrode active material, the positive electrode active material slurry is obtained;

[0043] Typical preparation process: 811 ternary material 97.3wt%, conductive carbon black 1wt%, carbon nanotube 0.5wt%, polyvin...

Embodiment 1

[0051] A preparation method of a lithium-ion battery positive electrode sheet with a safety coating, the method comprising the following steps:

[0052] Preparation of safety coating slurry: add base material airgel material, high stability positive electrode material, conductive agent and binder into dispersant, and disperse to obtain safety coating slurry;

[0053] Typical preparation process: silica airgel 20wt%, lithium iron phosphate 75wt%, carbon black 2wt%, polyvinylidene fluoride 3wt%, dispersant is NMP, slurry solid content 10wt%, stirring in a high-speed mixer for 4h , to obtain a safety coating slurry with a viscosity of 5000cp.

[0054] Preparation of positive electrode active material slurry: After mixing and stirring the raw materials of the positive electrode active material, the positive electrode active material slurry is obtained;

[0055] Typical preparation process: 811 ternary material 97.3wt%, conductive carbon black 1wt%, carbon nanotube 0.5wt%, polyvin...

Embodiment 2

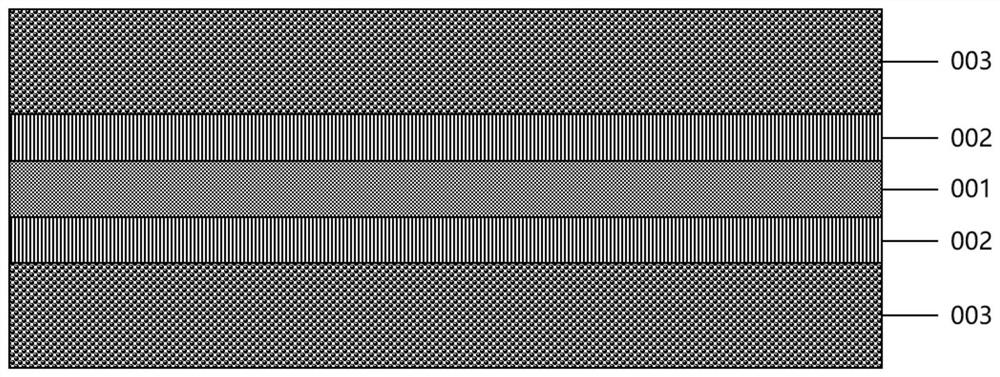

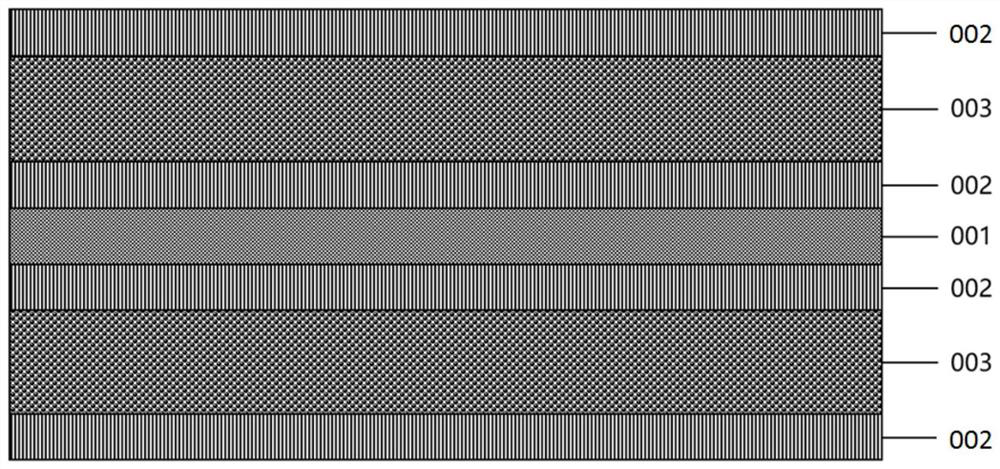

[0062] The difference from Example 1 is that the safety coating 002 is coated on the surface of the positive electrode current collector and the surface of the positive electrode sheet, and a three-layer extrusion coating machine is used to squeeze the upper and lower layers away from and close to the positive electrode current collector 001. The safety coating slurry is pressed, and the positive electrode active material slurry is extruded in the middle layer.

[0063] After drying, the other side of the current collector is coated, and the cross-section of the pole piece obtained after drying is as follows: image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com