Manganese oxide and nitrogen doped block carbon aerogel material as well as preparation and application thereof

A technology of manganese oxide and carbon airgel, which is applied in the direction of airgel preparation, alkali metal oxide/hydroxide, alkali metal compound, etc., can solve the problems of difficult balance between adsorption performance and regeneration stability, and achieve excellent Physical and chemical synergistic adsorption activity, excellent cycle adsorption stability, and improved adsorption activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

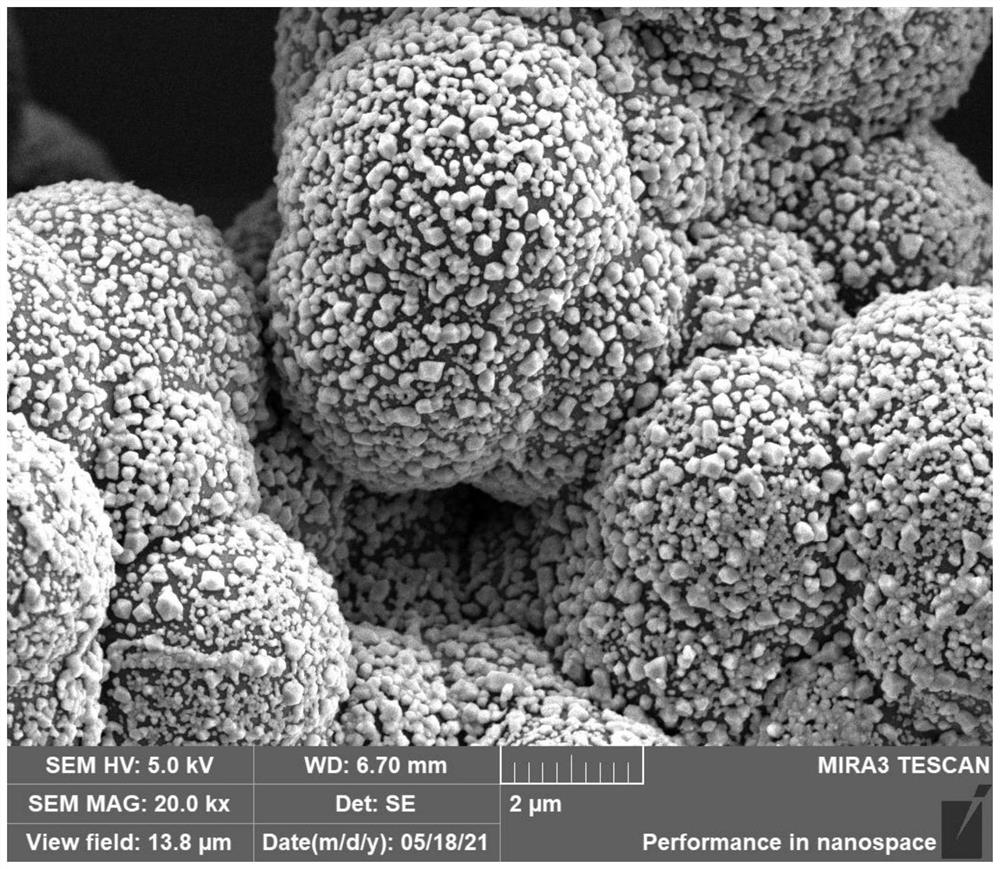

[0052] The preparation method of manganese nitrogen doped carbon airgel material, specifically, the method comprises the following steps:

[0053](1) Preparation of airgel precursor: Weigh 15g of phenolic resin and 3g of Formula 1 and dissolve in 100ml of anhydrous methanol, stir and mix until uniformly dissolved. Then the phenolic resin formula 1 mixed ethanol solution is sealed in a regular container, and placed in a constant temperature water bath (60° C.) at the gel temperature to carry out the sol gelation reaction. The solution just prepared is light yellow (color depth varies with the concentration of the reactant The increase and deepening), the water bath reaction (60 ℃) aging for 7 days, during which the color gradually darkened, and finally the wet gel was taken out. Dry at room temperature (25°C) for 1 day under normal pressure, and then dry in an oven for 1 day (65°C) to obtain a phenolic resin-based organic airgel precursor;

[0054] (2) Potassium permanganate s...

Embodiment 2

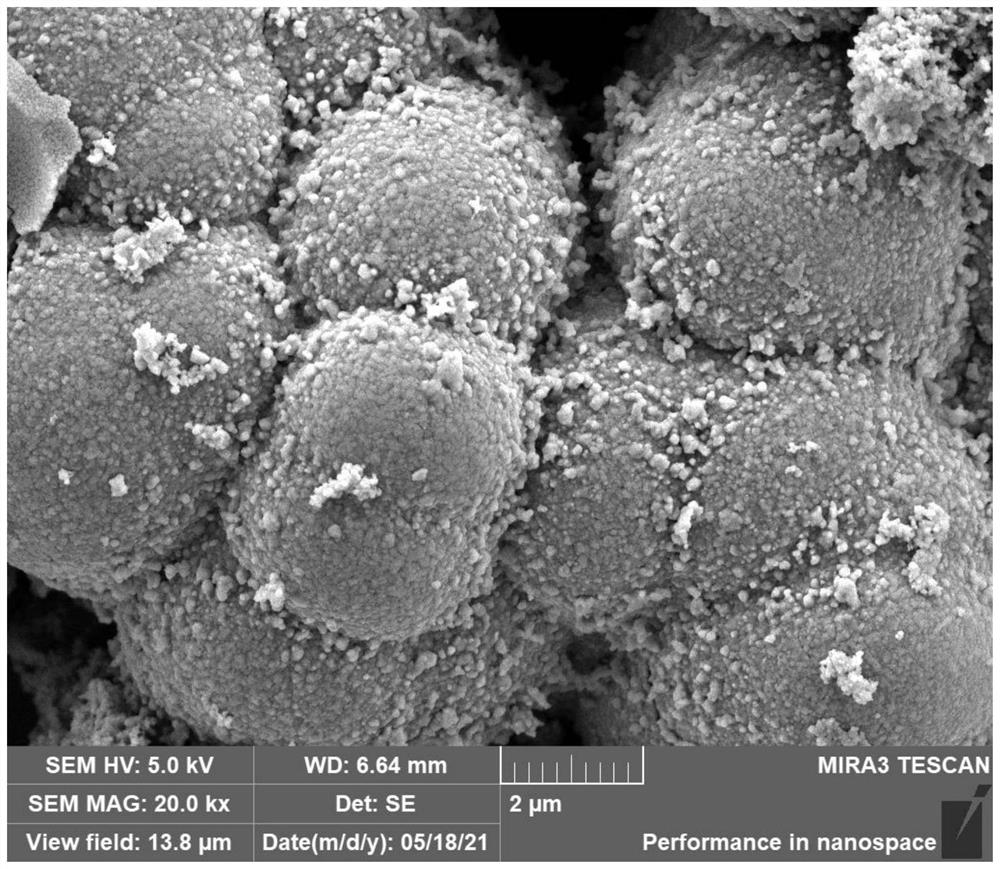

[0059] The preparation method of manganese nitrogen doped carbon airgel material, specifically, the method comprises the following steps:

[0060] (1) Preparation of airgel precursor: Weigh 15g of phenolic resin and 3g of Formula 1 and dissolve in 100ml of anhydrous methanol, stir and mix until uniformly dissolved. Then the phenolic resin formula 1 mixed ethanol solution is sealed in a regular container, and placed in a constant temperature water bath (60° C.) at the gel temperature to carry out the sol gelation reaction. The solution just prepared is light yellow (color depth varies with the concentration of the reactant The increase and deepening), the water bath reaction aging (60 ° C) for 7 days, during which the color gradually darkened, and finally the gel was taken out. Dry at room temperature (25°C) for 1 day under normal pressure, and then dry in an oven for 1 day (65°C) to obtain a phenolic resin-based organic airgel precursor;

[0061] (2) Potassium permanganate so...

Embodiment 3

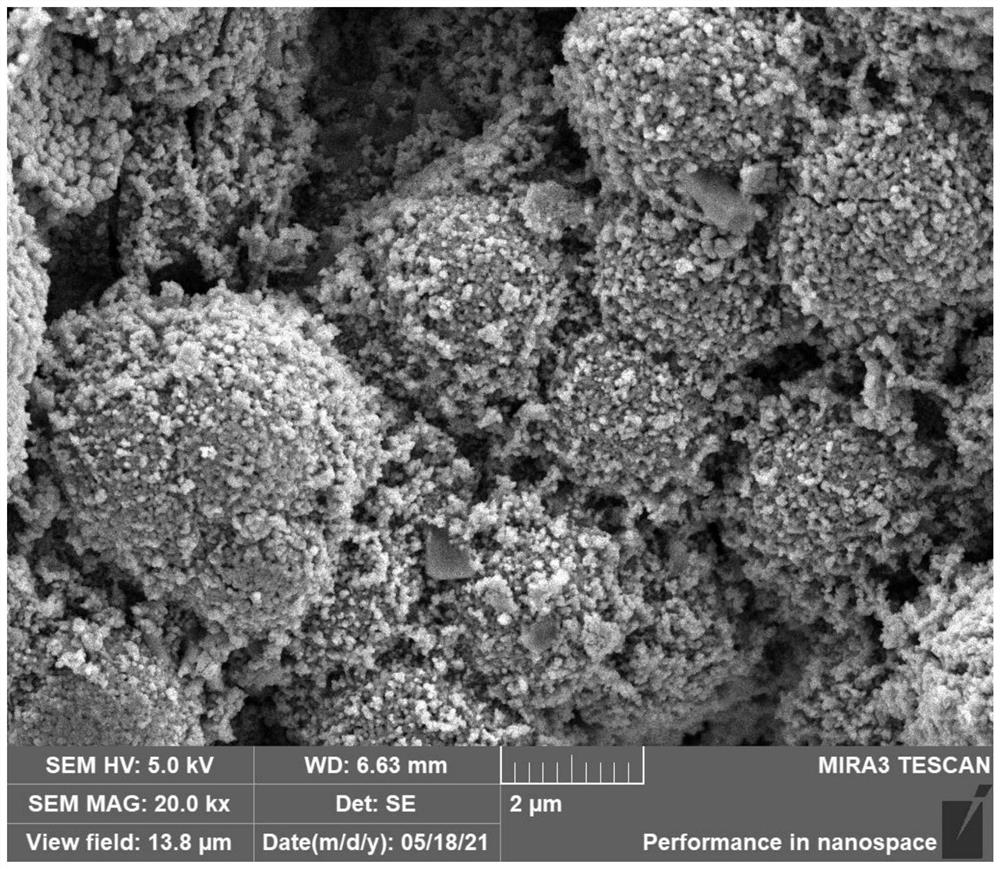

[0066] The preparation method of manganese nitrogen doped carbon airgel material, specifically, the method comprises the following steps:

[0067] (1) Preparation of airgel precursor: Weigh 15g of phenolic resin and 3g of Formula 1 and dissolve in 100ml of anhydrous methanol, stir and mix until uniformly dissolved. Then the phenolic resin formula 1 mixed ethanol solution is sealed in a regular container, and placed in a constant temperature water bath (60° C.) at the gel temperature to carry out the sol gelation reaction. The solution just prepared is light yellow (color depth varies with the concentration of the reactant The increase and deepening), the water bath reaction aging (60 ° C) for 7 days, during which the color gradually darkened, and finally the gel was taken out. Dry at room temperature (25°C) for 1 day under normal pressure, and then dry in an oven for 1 day (65°C) to obtain a phenolic resin-based organic airgel precursor;

[0068] (2) Potassium permanganate so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com