Magnetic suspension combined copper-molybdenum separation method

A magnetic levitation and copper-molybdenum technology, which is applied in the field of mineral processing, can solve the problems of difficult flotation separation, aggravated molybdenum inclusions, and large magnetic field forces, so as to reduce the amount of ore and flotation agents, reduce mutual inclusions, and reduce The effect of loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

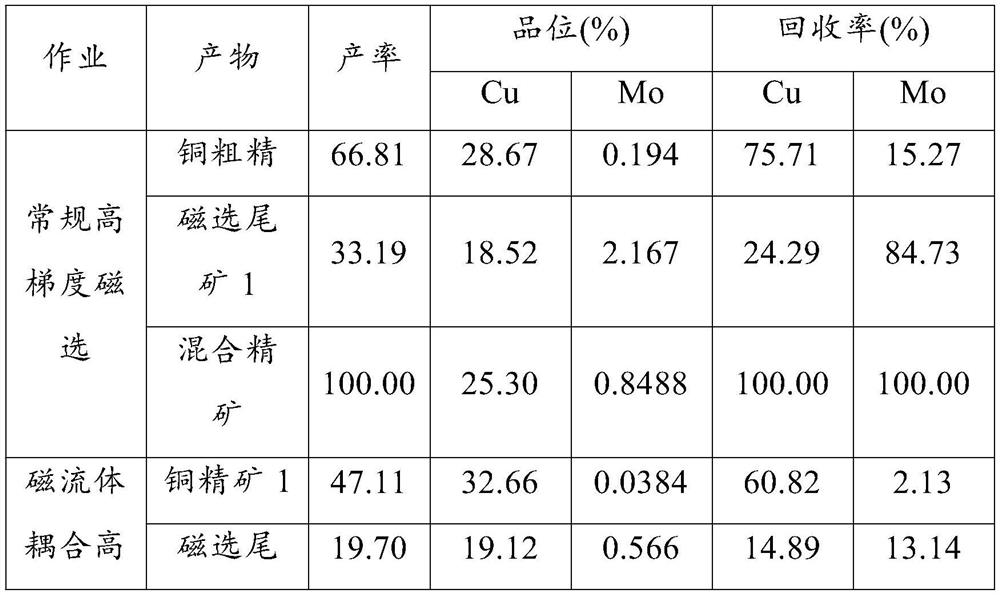

[0039] The copper-molybdenum mixed flotation concentrate of a domestic dressing plant has a Cu grade of 25.30% and a Mo grade of about 0.85%. The copper mineral is mainly chalcopyrite, and the molybdenum mineral is molybdenite.

[0040] Using magnetic fluid coupled pulsating high-gradient magnetic separation-flotation to separate copper-molybdenum mixed concentrate, the main steps are as follows:

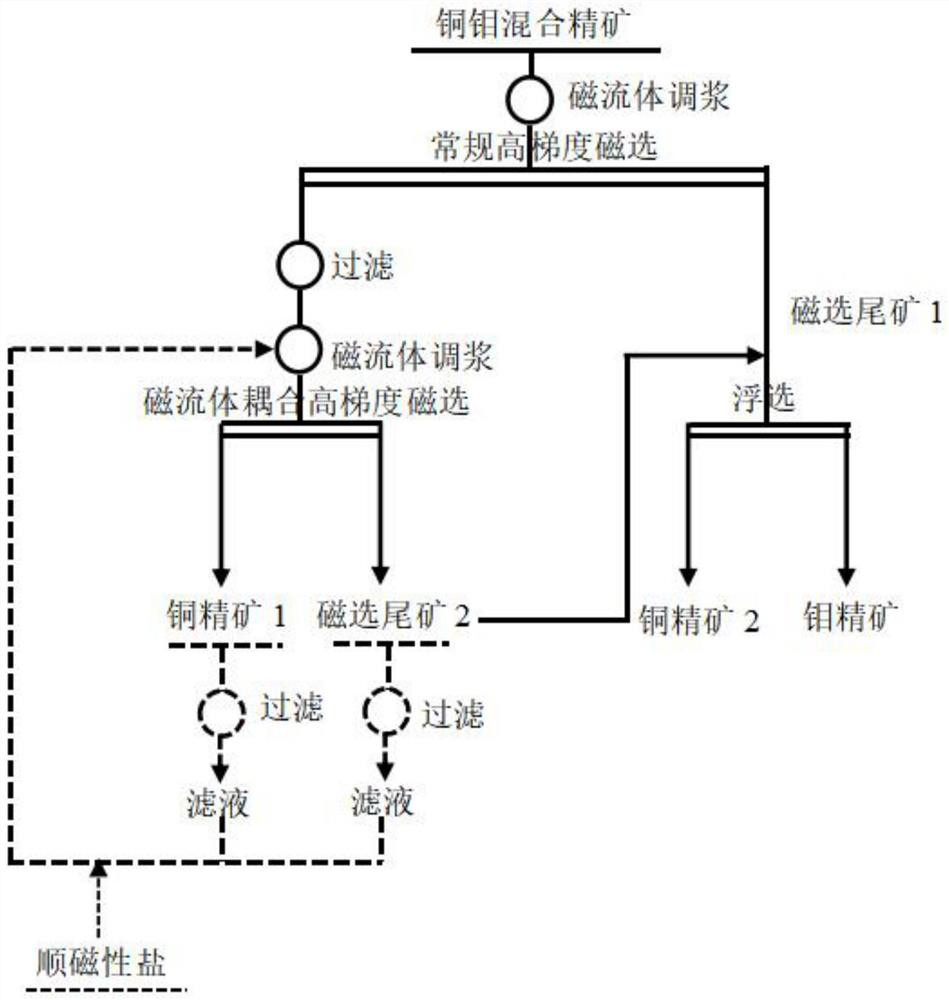

[0041] Process such as figure 1 As shown, the copper-molybdenum mixed concentrate was slurried with water to a solid particle concentration of 30%, stirred for 8 minutes to remove part of the flotation agent, and a vertical ring pulsating high-gradient magnetic separator was used for roughing. The background magnetic induction intensity was 1.8T, and a 2mm Rod medium, pulsation frequency 120r / min, stroke 10mm, natural slurry flow rate, to obtain copper rough and fine 1 and magnetic separation tailings 1.

[0042] The coarse copper concentrate obtained by conventional pulsating high...

Embodiment 2

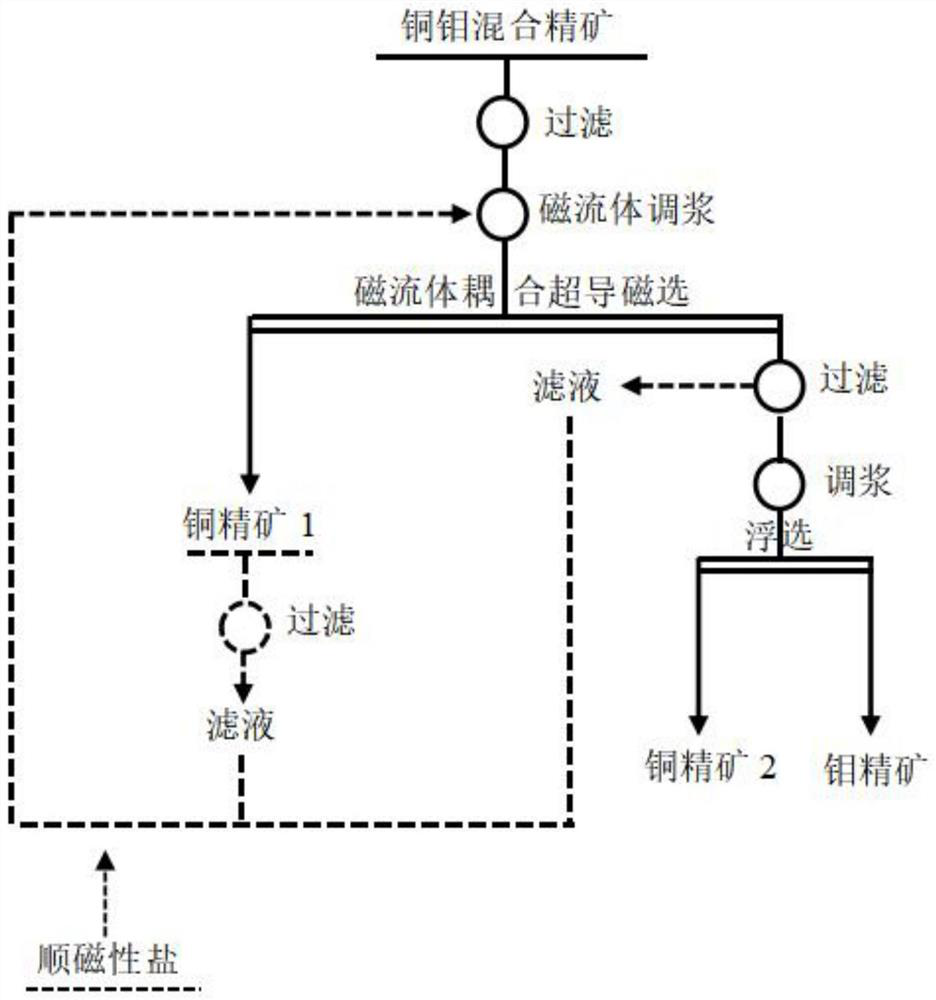

[0050] Using magnetic fluid coupled superconducting magnetic separation-flotation to separate copper-molybdenum mixed concentrate, the main steps are as follows:

[0051] Process such as figure 2 As shown, the copper-molybdenum mixed concentrate is filtered to a water content of 10%, and the mass concentration of 2% manganese chloride solution is used to adjust the slurry to a solid particle mass concentration of about 25%. After slurry mixing, superconducting magnetic separation is carried out, the background magnetic induction intensity is 5T, the mesh medium is used, the pulp flow rate is 0.06m / s, and the pulse frequency is 30r / min to obtain copper concentrate 1 and magnetic separation tailings, which are filtered separately. The obtained filtrate is adjusted to a concentration of 2% by adding an appropriate amount of manganese chloride, and then continues to be used for slurry adjustment of the mixed concentrate after filtration, so as to realize recycling.

[0052] Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com