Olefin polymerization catalyst carrier, preparation method thereof and olefin polymerization catalyst component

A catalyst carrier, a technology for olefin polymerization, applied in the field of olefin polymerization catalyst carrier, preparation of olefin polymerization catalyst carrier, and olefin polymerization catalyst component, can solve the problem of difficulty in obtaining magnesium alkoxides, improve particle shape, increase strength, Reduce the effect of shattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] In the reaction kettle of 1.0L, add polyvinylpyrrolidone (PVP, molecular weight=58000) 1.6g successively, ethanol 2.8mol, magnesium chloride 0.2mol, ferrous chloride 2mmol, triethanolamine 2mmol, under stirring (450rpm) be warming up to 70 °C. After 1 hour of constant temperature reaction, 0.6 mol of epichlorohydrin was added, the temperature was maintained for 0.5 hour, the liquid was filtered off, the solid was washed 5 times with hexane, and dried in vacuum to obtain solid component particles. Through nuclear magnetic resonance, elemental analysis and gas chromatography characterization, the carrier structure is as follows:

[0082]

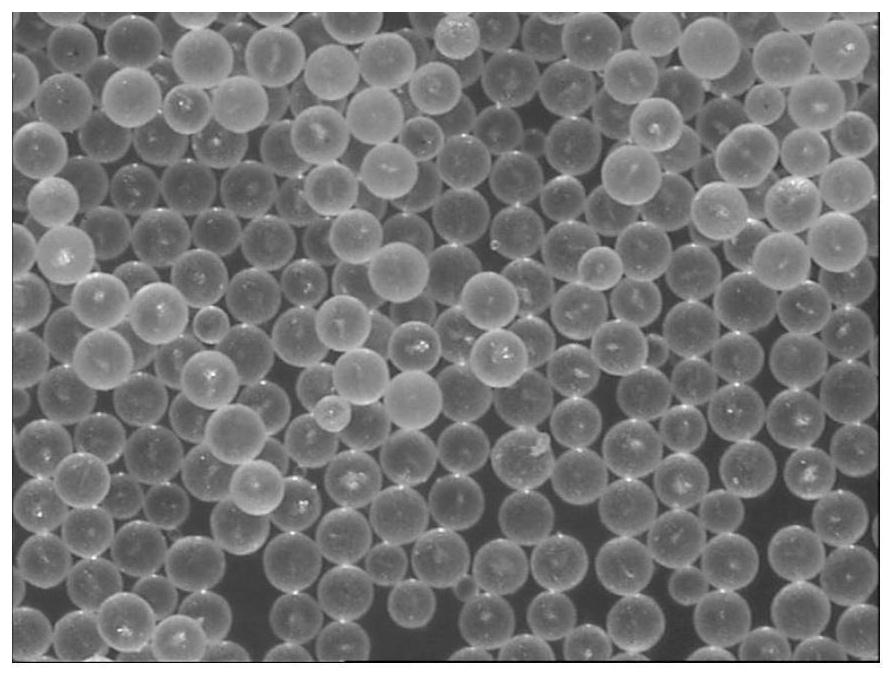

[0083] Carrier particle size distribution D50=71.1μm, Span=0.65, see the particle shape figure 1 .

Embodiment 2

[0085] The difference between the preparation method and Example 1 is only that the addition amount of ferrous chloride is 4 mmol. Through nuclear magnetic resonance, elemental analysis and gas chromatography characterization, the carrier structure is as follows:

[0086]

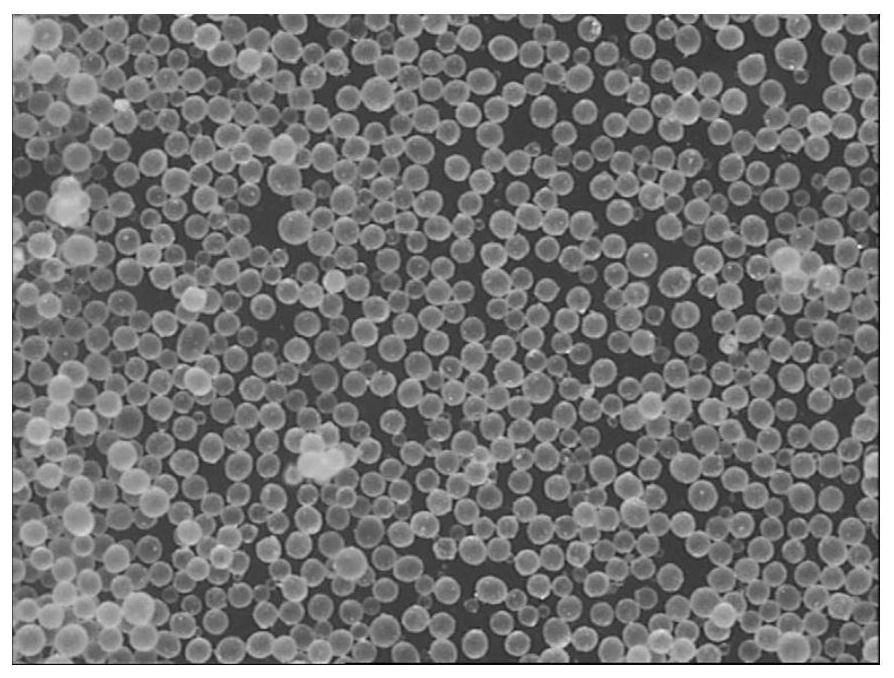

[0087] Carrier particle size distribution D50=68.2 μm, Span=0.67.

Embodiment 3

[0089] The difference between the preparation method and Example 1 is only that the amount of ferrous chloride added is 8 mmol. Through nuclear magnetic resonance, elemental analysis and gas chromatography characterization, the carrier structure is as follows:

[0090]

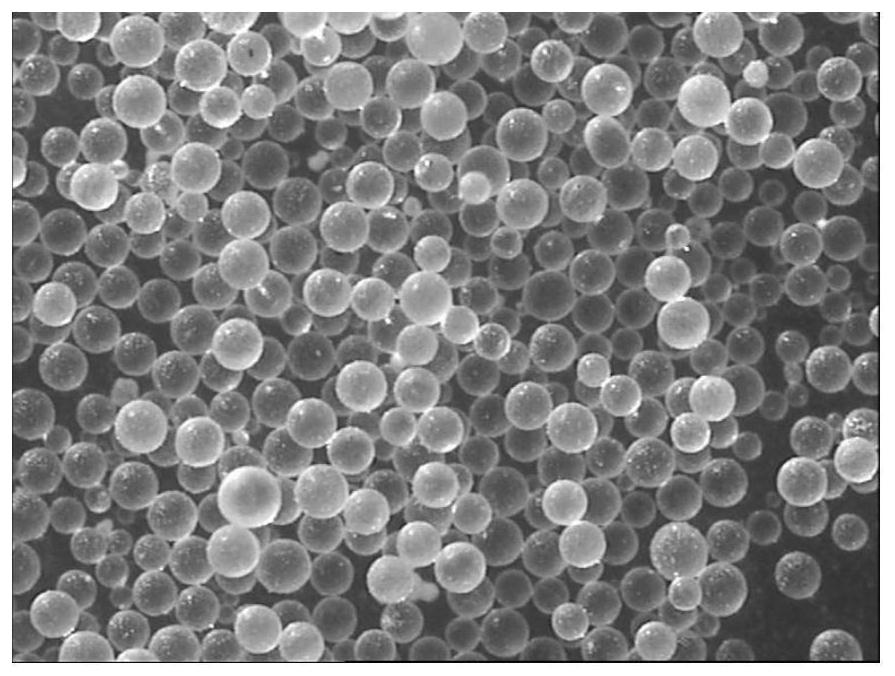

[0091] Carrier particle size distribution D50=39.8 μm, Span=0.68.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com