Preparation process of high-modified wear-resistant PVC (polyvinyl chloride) material cable sheath

A PVC material and preparation process technology, applied in the field of materials, can solve problems such as affecting the use of PVC materials, insufficient wear resistance, etc., and achieve the effects of strong design applicability, reduced thermal conductivity, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

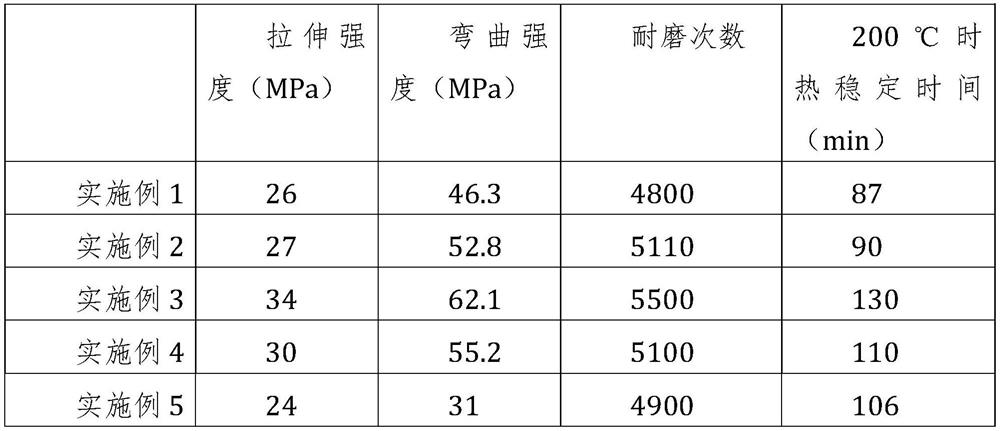

Examples

Embodiment 1

[0022] A highly modified wear-resistant PVC material cable, wherein the main materials used include the following raw materials in parts by weight: 50 parts of PVC resin, 20 parts of EPDM resin, 40 parts of LDPE resin, 5 parts of glass fiber, 5 parts of carbon fiber, polyester 3 parts of ester fiber, 3 parts of polyaramid fiber, 10 parts of polylactic acid, 0.25 parts of silane coupling agent, 5 parts of inorganic filler, 6 parts of activated calcium carbonate, 5 parts of wear-resistant modifier, 3 parts of lubricant, plasticizer 1 part of agent, 0.8 part of insoluble sulfur.

[0023] Further, the inorganic filler is a mixture of mica powder, brucite powder, fumed silica calcium carbonate, kaolin, talcum powder, boron slag, graphite fluoride and quartz powder.

[0024] Further, the wear-resistant modifier is a mixture of styrene-butadiene rubber and natural rubber.

[0025] Further, the silane coupling agent is a mixture of polysiloxane, diphenyl ether and polyimide.

[0026...

Embodiment 2

[0036] A highly modified wear-resistant PVC material cable sheath, wherein the main materials used include the following raw materials in parts by weight: 50 parts of PVC resin, 20 parts of EPDM resin, 40 parts of LDPE resin, 5 parts of glass fiber, 5 parts of carbon fiber, 3 parts of polyester fiber, 3 parts of polyaramid fiber, 10 parts of polylactic acid, 0.25 parts of silane coupling agent, 5 parts of inorganic filler, 6 parts of activated calcium carbonate, 5 parts of wear-resistant modifier, 3 parts of lubricant, 1 part of plasticizer, 0.8 part of insoluble sulfur.

[0037] Further, the inorganic filler is a mixture of mica powder, brucite powder, fumed silica calcium carbonate, kaolin, talcum powder, boron slag, graphite fluoride and quartz powder.

[0038] Further, the wear-resistant modifier is a mixture of styrene-butadiene rubber and natural rubber.

[0039] Further, the silane coupling agent is a mixture of polysiloxane, diphenyl ether and polyimide.

[0040] Fur...

Embodiment 3

[0050] A highly modified wear-resistant PVC material cable, wherein the main materials used include the following raw materials in parts by weight: 65 parts of PVC resin, 23 parts of EPDM resin, 50 parts of LDPE resin, 7 parts of glass fiber, 7 parts of carbon fiber, polyester 4 parts of ester fiber, 4 parts of polyaramid fiber, 20 parts of polylactic acid, 0.4 part of silane coupling agent, 7 parts of inorganic filler, 7 parts of activated calcium carbonate, 6 parts of wear-resistant modifier, 4.5 parts of lubricant, plasticizer 1.5 parts of agent, 0.9 parts of insoluble sulfur.

[0051] Further, the inorganic filler is a mixture of mica powder, brucite powder, fumed silica calcium carbonate, kaolin, talcum powder, boron slag, graphite fluoride and quartz powder.

[0052] Further, the wear-resistant modifier is a mixture of styrene-butadiene rubber and natural rubber.

[0053] Further, the silane coupling agent is a mixture of polysiloxane, diphenyl ether and polyimide.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com