Non-crosslinked PVC (polyvinyl chloride) material

A PVC material, non-cross-linking technology, applied in the direction of plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems of insufficient heat resistance, etc., and achieve reasonable proportioning, good flexibility, and good extrusion processing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

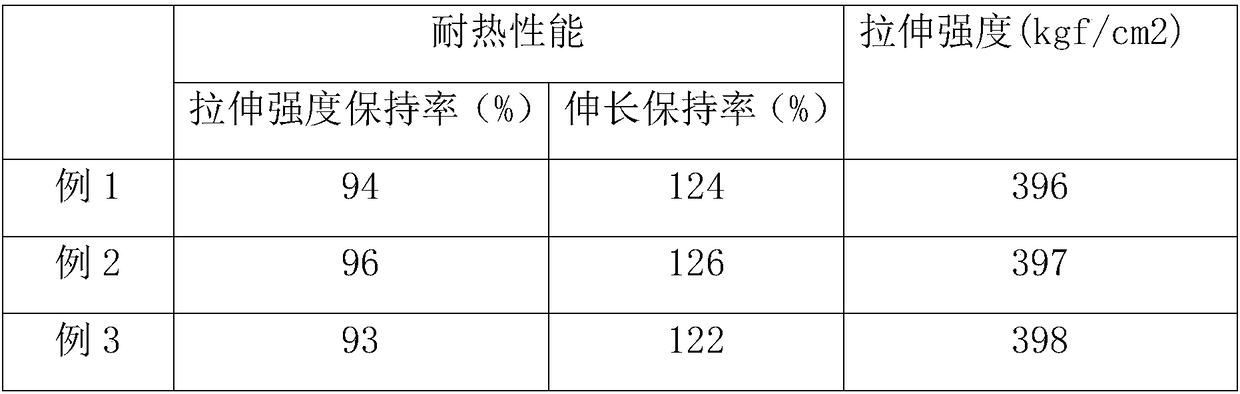

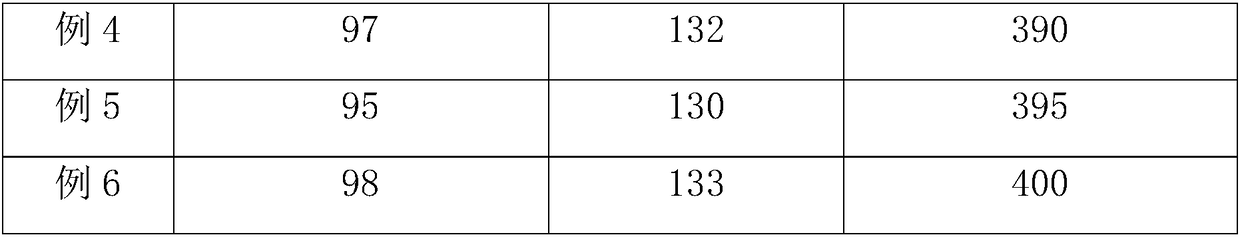

Examples

Embodiment 1

[0015] The non-crosslinked PVC material of the present embodiment, raw material comprises the following components by weight:

[0016] 30 parts of PVC resin, 4 parts of styrene, 4 parts of 3-(2-furyl)acrylic acid, 4 parts of ethyl cinnamate, 5 parts of trioctyl trimellitate, 0.5 parts of epoxy soybean oil, 1 part of calcium carbonate , 1 part of calcium zinc composite stabilizer, 1 part of dimethyl sulfoxide, 1 part of triphenyl phosphate, 1 part of dimethyl acetal, 2 parts of cinnamoyl chloride, 1 part of diethylamine, 1 part of triethylamine, 0.5 parts of 2,3-dimethyl-2,3-diphenylbutane, 0.5 parts of dibenzoyl peroxide;

[0017] The PVC resin is composed of a PVC resin with a homopolymerization degree of 1300 and a PVC resin of 1500, and the weight ratio is 1:1;

[0018] First add cinnamoyl chloride, diethylamine and triethylamine to petroleum ether, stir and react at a temperature of 35°C for 24 hours, then distill under reduced pressure, dry in vacuum at a temperature of ...

Embodiment 2

[0020] The non-crosslinked PVC material of the present embodiment, raw material comprises the following components by weight:

[0021] 40 parts of PVC resin, 8 parts of styrene, 8 parts of 3-(2-furyl)acrylic acid, 8 parts of ethyl cinnamate, 10 parts of trioctyl trimellitate, 3 parts of epoxidized soybean oil, 4 parts of calcium carbonate , 4 parts of calcium zinc composite stabilizer, 4 parts of dimethyl sulfoxide, 4 parts of triphenyl phosphate, 4 parts of dimethyl acetal, 4 parts of cinnamoyl chloride, 3 parts of diethylamine, 3 parts of triethylamine, 2 parts of 2,3-dimethyl-2,3-diphenylbutane, 2 parts of dibenzoyl peroxide;

[0022] The PVC resin is composed of a PVC resin with a homopolymerization degree of 1300 and a PVC resin of 1500, and the weight ratio is 1:1;

[0023] First add cinnamoyl chloride, diethylamine and triethylamine to petroleum ether, stir and react at a temperature of 50°C for 24 hours, then distill under reduced pressure, dry in vacuum at a temperat...

Embodiment 3

[0025] The non-crosslinked PVC material of the present embodiment, raw material comprises the following components by weight:

[0026] 30 parts of PVC resin, 8 parts of styrene, 4 parts of 3-(2-furyl)acrylic acid, 8 parts of ethyl cinnamate, 5 parts of trioctyl trimellitate, 3 parts of epoxy soybean oil, 1 part of calcium carbonate , 4 parts of calcium zinc composite stabilizer, 1 part of dimethyl sulfoxide, 4 parts of triphenyl phosphate, 1 part of dimethyl acetal, 4 parts of cinnamoyl chloride, 1 part of diethylamine, 3 parts of triethylamine, 0.5 parts of 2,3-dimethyl-2,3-diphenylbutane, 2 parts of dibenzoyl peroxide;

[0027] The PVC resin is composed of a PVC resin with a homopolymerization degree of 1300 and a PVC resin of 1500, and the weight ratio is 1:1;

[0028] First add cinnamoyl chloride, diethylamine and triethylamine to petroleum ether, stir and react at a temperature of 35°C for 24 hours, then distill under reduced pressure, dry in vacuum at a temperature of 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com