Electro-Fenton cathode material and preparation method and application thereof

A cathode material, the technology of electro-Fenton, applied in the field of electrocatalysis, can solve the problems of low stability of electro-Fenton cathode materials, complex preparation methods, high preparation costs, etc., to achieve accelerated electrocatalytic reaction performance, simple preparation method, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The present embodiment provides a kind of preparation method of electric Fenton cathode material, and described preparation method comprises:

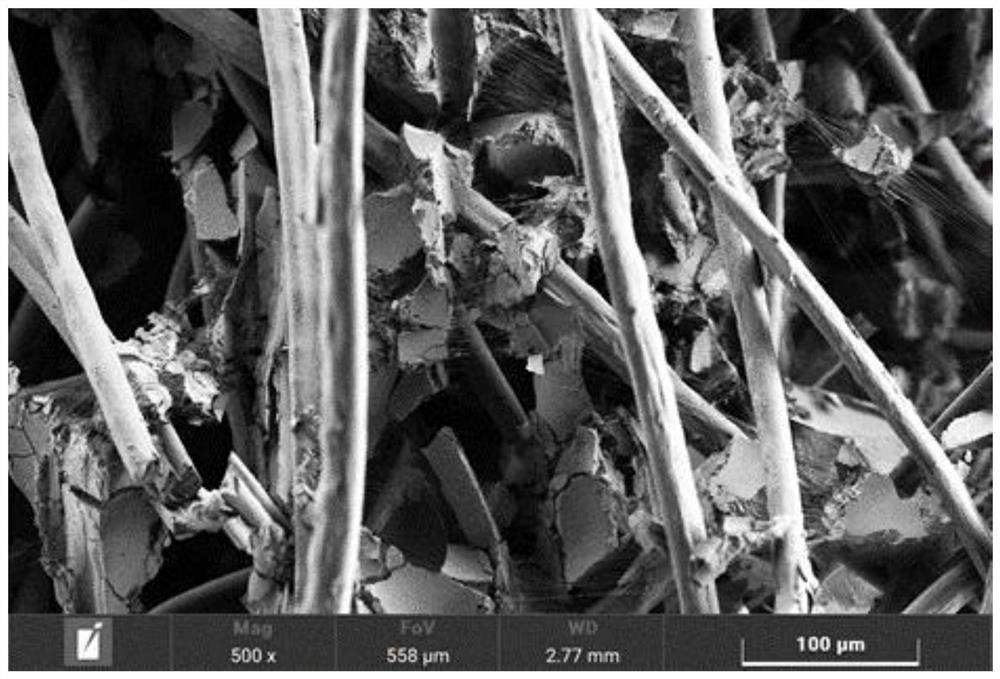

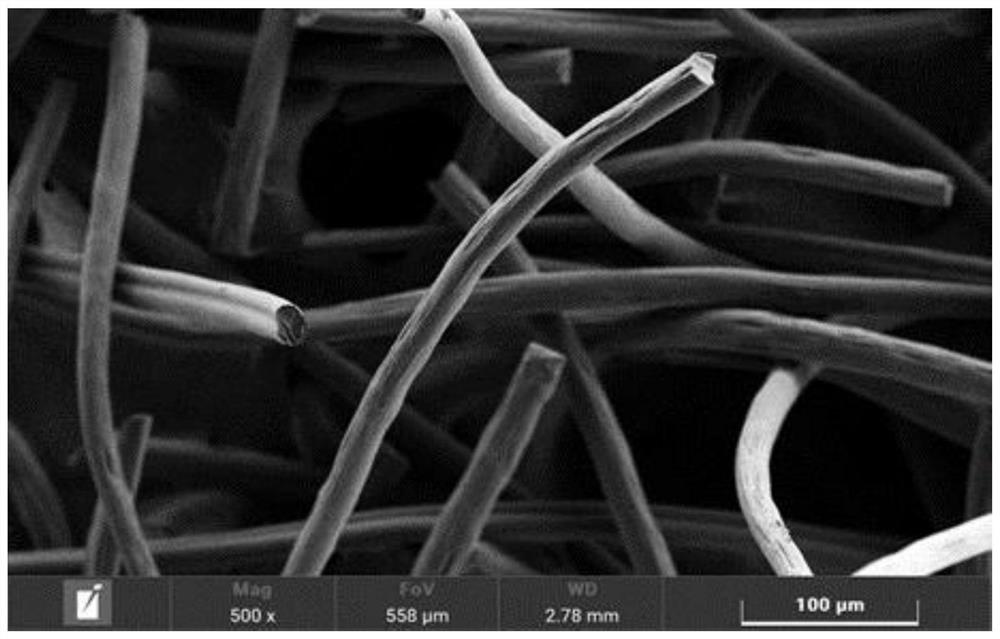

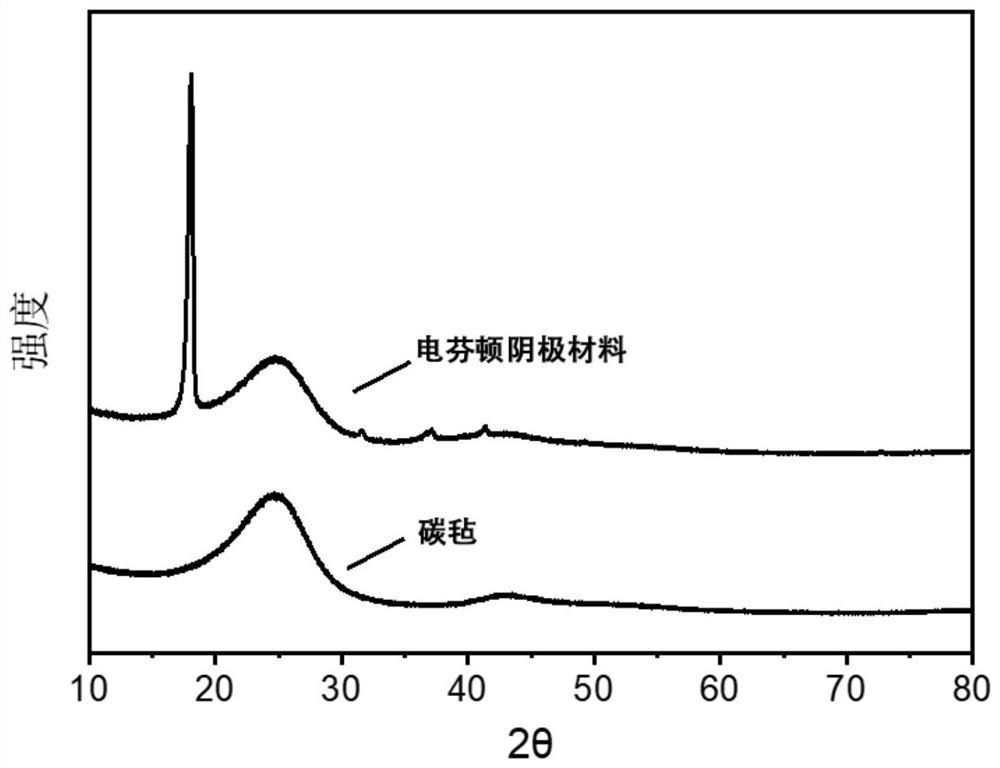

[0077] A carbon felt of 2cm×3cm×0.5cm was soaked in deionized water and ethanol ultrasonically for 40min, dried at 90°C for 25min, and heated under reflux at 60°C for 4h using concentrated nitric acid with a mass fraction of 55wt%. Ultrasonic soak until the cleaning solution is neutral, dry at 105°C for 25min; soak in 6wt% polytetrafluoroethylene dispersion for 35min, dry at 105°C for 35min; in a nitrogen atmosphere at 8°C / The heating rate of min was raised to 350° C. and kept for 105 min to obtain the electric Fenton cathode material.

Embodiment 2

[0079]The present embodiment provides a kind of preparation method of electric Fenton cathode material, and described preparation method comprises:

[0080] A carbon felt of 2cm×3cm×0.5cm was soaked in deionized water and ethanol ultrasonically for 30min, dried at 105°C for 35min, and heated to reflux at 75°C for 2h with concentrated nitric acid with a mass fraction of 70wt%. Ultrasonic soak until the cleaning solution is neutral, dry at 90°C for 45min; soak in 15wt% polytrifluorochloroethylene dispersion for 65min, dry at 120°C for 10min; The heating rate of ℃ / min was raised to 420 ℃ and kept for 75 minutes to obtain the electric Fenton cathode material.

Embodiment 3

[0082] The present embodiment provides a kind of preparation method of electric Fenton cathode material, and described preparation method comprises:

[0083] A carbon felt of 2cm×3cm×0.5cm was soaked in deionized water and ethanol ultrasonically for 50min, dried at 75°C for 45min, and heated at reflux for 3h at 75°C using concentrated nitric acid with a mass fraction of 40wt%. Ultrasonic soak until the cleaning solution is neutral, dry at 75°C for 35min; soak in a polyvinylidene fluoride dispersion with a mass fraction of 1wt% for 90min, and dry at 75°C for 45min; in an argon atmosphere at 6°C Raise the temperature to 280°C at a heating rate of 1 / min and hold it for 90 minutes to obtain the electric Fenton cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com