Coalescence material as well as preparation method and oil removal method thereof

A technology for coalescing materials and base materials, applied in separation methods, chemical instruments and methods, grease/oily substances/suspton removal devices, etc., can solve complex preparation process, poor emulsified oil effect, and coalescence effect needs to be further improved and other problems, to achieve the effect of simple preparation method, low surface energy, and excellent lipophilic and hydrophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

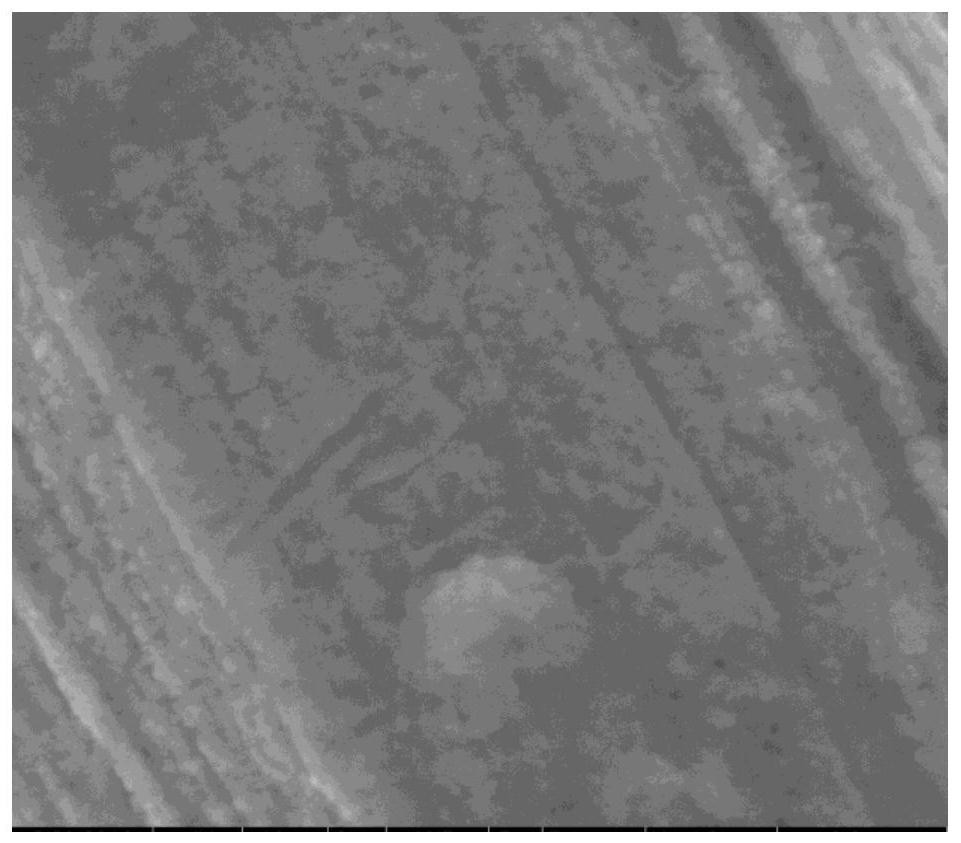

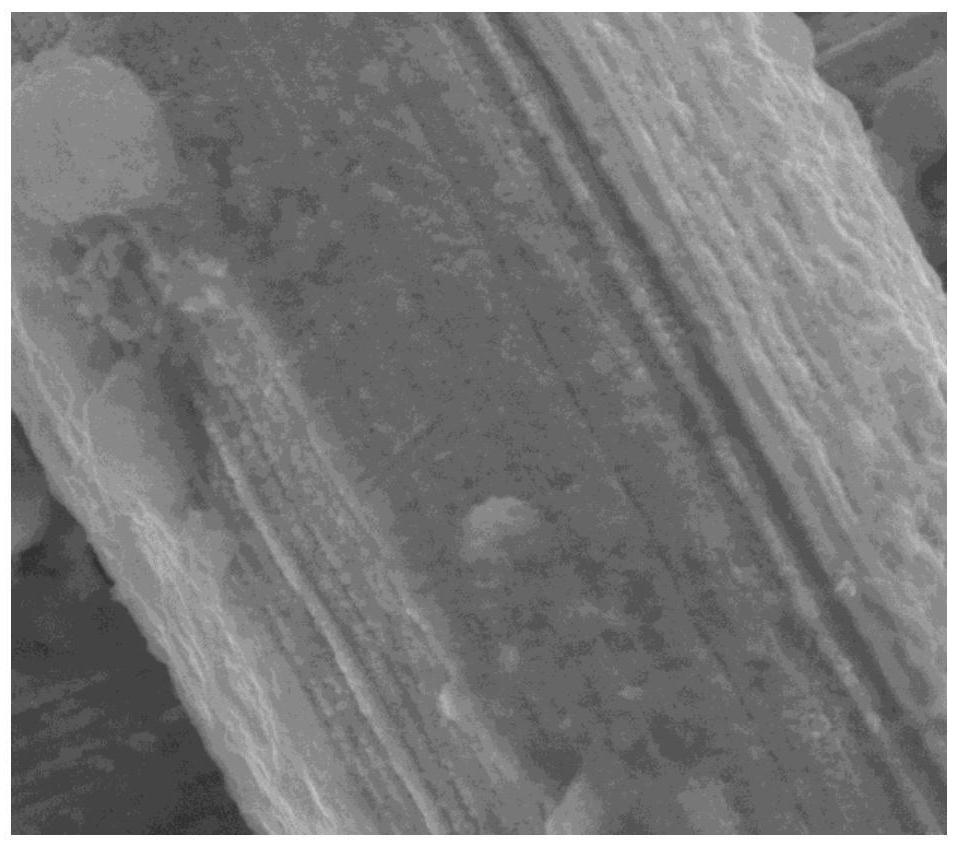

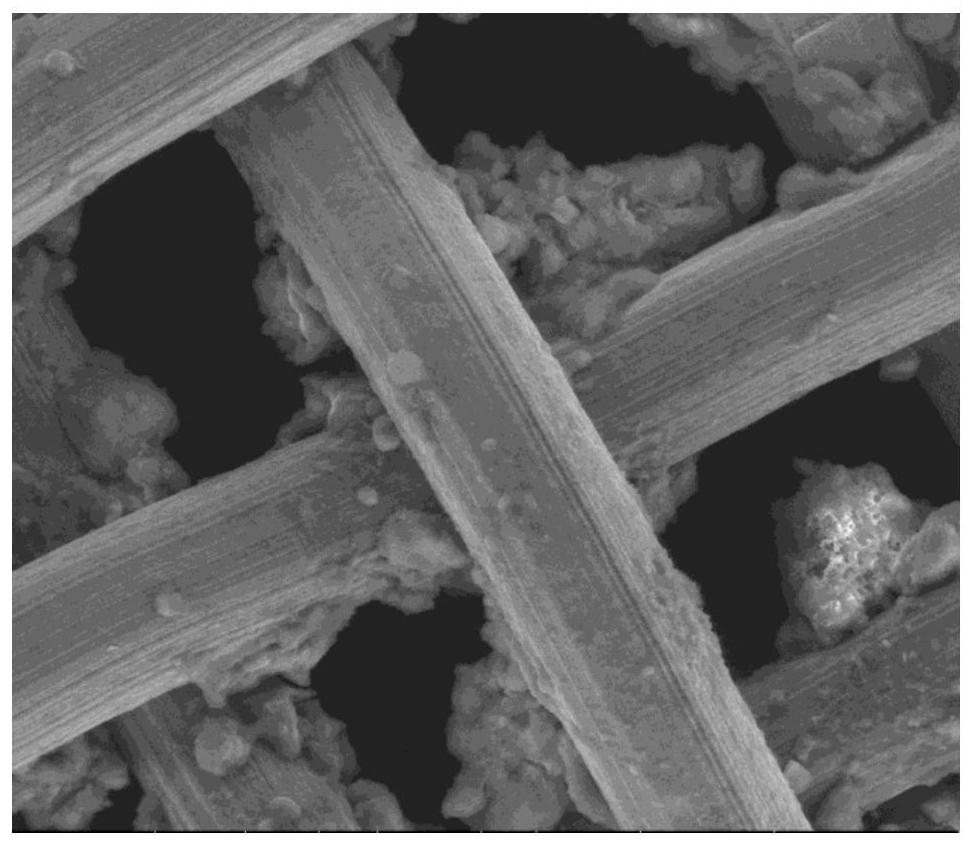

[0044] The preparation method of the coalescing material in Example 1 comprises the following steps: (1) placing the inorganic base material in absolute ethanol and deionized water successively, ultrasonically washing them for 25 min and 10 min respectively, and then drying them; The siloxane solution is coated on the inorganic base material, dried and solidified in a vacuum oven at 98° C. for 5 hours, then placed in a muffle furnace, fired at 490° C. for 2.5 hours, and cooled to room temperature to obtain an intermediate material; ( 2) Coating the second polysiloxane solution on the intermediate material, drying and curing in a vacuum oven at 98° C. for 5 hours to obtain the coalescence material of the present invention.

Embodiment 2

[0045] The preparation method of the coalescing material in Example 2 comprises the following steps: (1) placing the inorganic base material in absolute ethanol and deionized water successively, ultrasonic cleaning for 20 min respectively, and then drying it; the first polysiloxane The alkane solution is coated on the inorganic base material, dried and solidified in a vacuum oven at 100°C for 4 hours, then placed in a muffle furnace, fired at 550°C for 3 hours, and cooled to room temperature to obtain an intermediate material; (2) The second polysiloxane solution was coated on the intermediate material, dried and cured in a vacuum oven at 100° C. for 4 hours to obtain the coalescence material of the present invention.

Embodiment 3

[0046] The preparation method of the coalescing material in Example 3 comprises the following steps: (1) placing the inorganic base material in absolute ethanol and deionized water successively, ultrasonic cleaning for 20 min respectively, and then drying it; the first polysiloxane The alkane solution is coated on the inorganic base material, dried and solidified in a vacuum oven at 105°C for 4h, then placed in a muffle furnace, fired at 550°C for 3h, and cooled to room temperature to obtain an intermediate material; (2) The second polysiloxane solution was coated on the intermediate material, dried and cured in a vacuum oven at 105° C. for 3.5 hours to obtain the coalescence material of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com