Wall breaking method for preparing nanoscale selenium-enriched yeast

A selenium-enriched yeast, nano-scale technology, applied in the field of photocatalysis and biology, can solve the problems of high price of reagents, loss of effective components, and poor popularity, and achieve good size uniformity, improve absorption and utilization, and improve destruction. The effect of wall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Prepare 50mL of Zn(NO 3 ) 2 solution and NaOH solution, the NaOH solution was mixed with Zn(NO 3 ) 2 Mix the solutions, continue to stir for 20 minutes, transfer to a centrifuge tube and centrifuge for 5 minutes at a speed of 6000 rpm, discard the supernatant, wash the precipitate with distilled water once, discard the supernatant after centrifugation, and disperse the precipitate in 80mL with a concentration of 1mol / L H 2 o 2 In the solution, under the condition of sufficient stirring, heat to 75°C, stir for 1h, centrifuge for 10min at 8000rpm, wash the precipitate once with distilled water and absolute ethanol, and dry at 80°C for 30min to obtain the ZnO precursor. Then it was placed in a crucible, heat-treated at 400° C. for 2 h, cooled to room temperature, and then taken out to obtain photocatalytically excited ZnO powder.

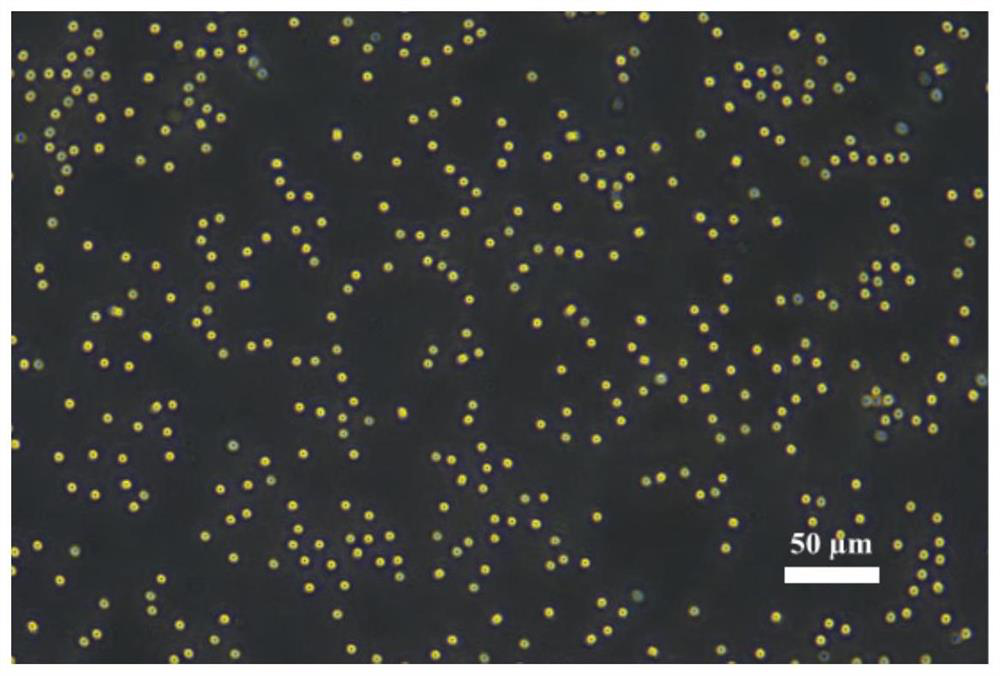

[0044] Weigh 10 g of selenium-enriched yeast dry powder, dissolve it in water, and prepare a selenium-enriched yeast suspension with a mas...

Embodiment 2

[0048] Weigh 10 g of selenium-enriched yeast dry powder, dissolve it in water, and prepare a selenium-enriched yeast suspension with a mass fraction of 10%. Add 200mg of the ZnO powder obtained in Example 1 to the above-mentioned selenium-enriched yeast suspension, stir evenly at 1200r / min, and place it in a dark box. Under continuous stirring at the same speed, the selenium-enriched yeast suspension is illuminated for 40min, and the light source The distance from the liquid surface of the suspension is about 20 cm, and then centrifuged at 800 r / min for 1 min to obtain a photocatalytic selenium-enriched yeast suspension.

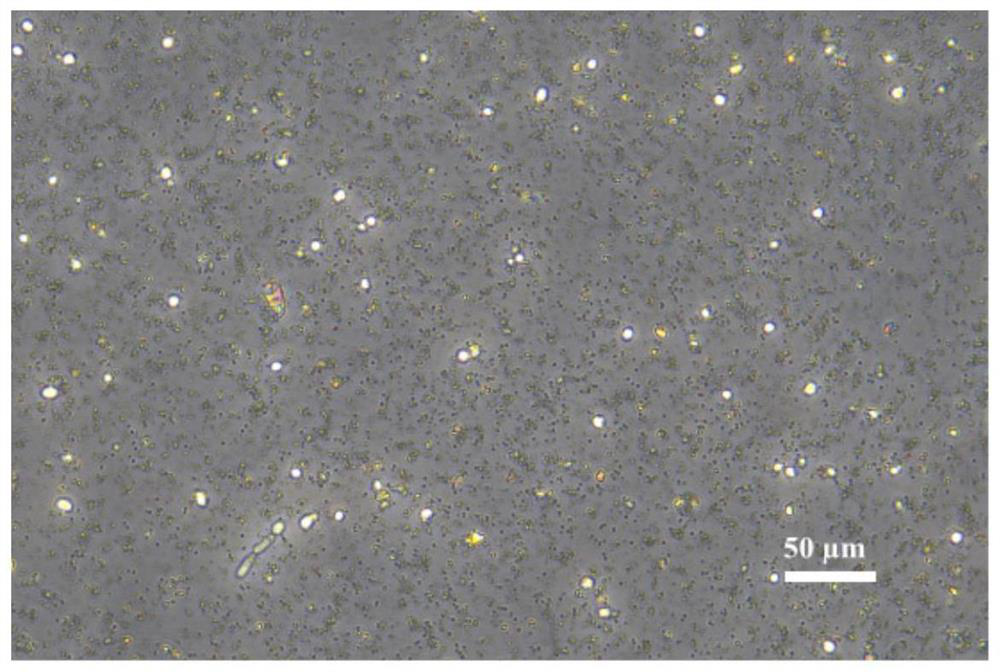

[0049] Then pour the selenium-enriched yeast suspension into a ball mill for grinding, use zirconia as the impact ball, the ball-to-material ratio is 3:1, the ball diameter is 2-3cm, the speed is 500rpm, take it out after 1 hour of ball milling, and use an ultrasonic cell disruptor Ultrasonic treatment for 10 minutes, power 300W, repeated ball milling and ul...

Embodiment 3

[0051] Weigh 10 g of selenium-enriched yeast dry powder, dissolve it in water, and prepare a selenium-enriched yeast suspension with a mass fraction of 10%. Add 200 mg of the ZnO powder obtained in Example 1 to the above-mentioned selenium-enriched yeast suspension, stir evenly at 1000 r / min, and place it in a dark box. With constant stirring at the same speed, irradiate the selenium-enriched yeast suspension for 40 minutes. The distance from the liquid surface of the suspension is about 20 cm, and centrifuged at 650 r / min for 1.5 min to obtain a photocatalytic selenium-enriched yeast suspension.

[0052] Then pour the selenium-enriched yeast suspension into a ball mill for grinding, use zirconia as the impact ball, the ball-to-material ratio is 3:1, the ball diameter is 2-3cm, the speed is 500rpm, take it out after 1 hour of ball milling, and use an ultrasonic cell disruptor Ultrasonic treatment for 10 minutes, power 300W, repeated ball milling and ultrasonic treatment, the t...

PUM

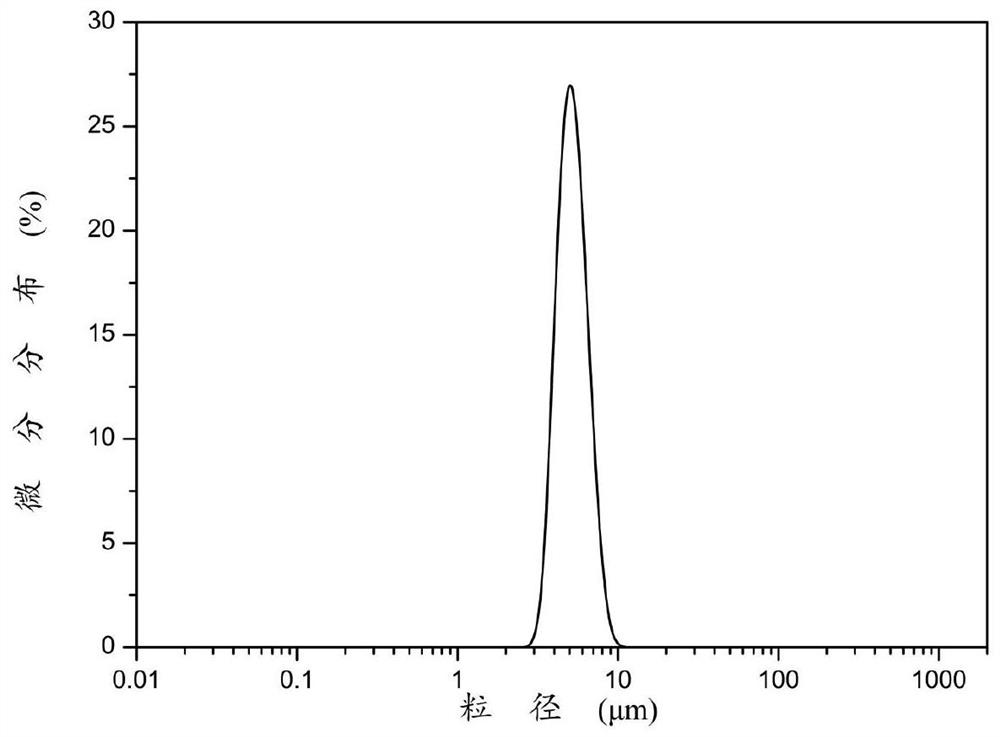

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com