Preparation method and device of fructo-oligosaccharide with high kestose content

A technology of kestose and fructooligosaccharides, which is applied in the field of preparation of fructooligosaccharides, can solve the inconvenient work of the continuous conduction water bath of the mixture, the inability to realize the mixing and transmission of raw materials, the inconvenient work of the continuous conduction water bath, etc. problems, to achieve the effect of efficient integrated production work, convenient temperature control work, and convenient sealing production work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

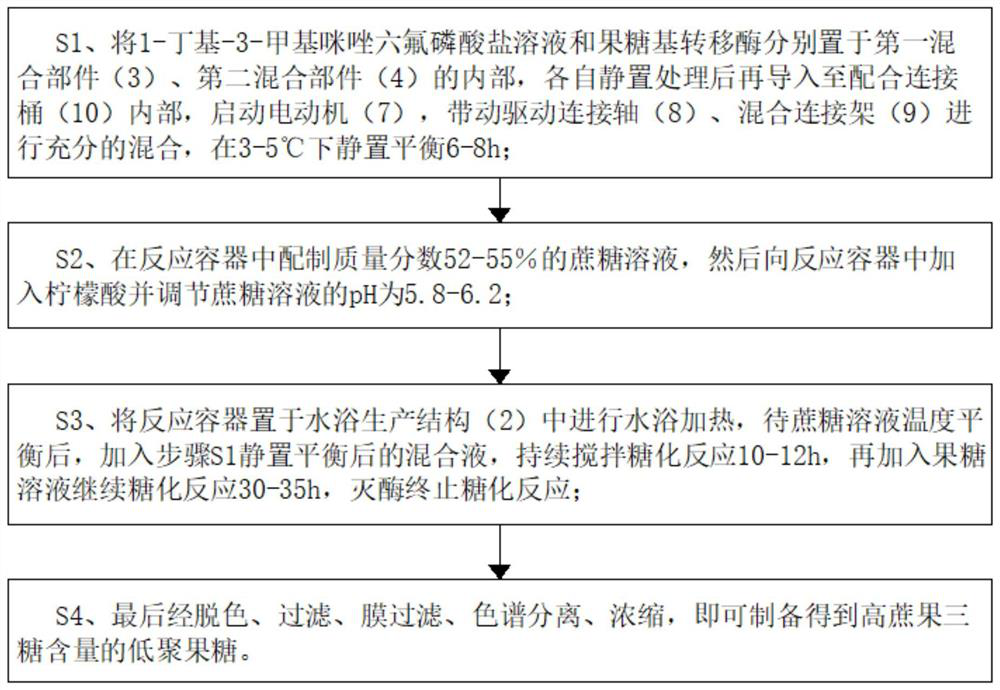

[0056] Fructose-oligosaccharides high in kestose, see figure 1 , its preparation process comprises the following steps:

[0057] S1. Place the 1-butyl-3-methylimidazolium hexafluorophosphate solution and the fructosyltransferase in the first mixing part and the second mixing part respectively, and then import them into the matching connecting barrel after standing for treatment , start the motor, drive the drive connecting shaft and the mixing connection frame to fully mix, and let it stand at 3°C for 6 hours;

[0058] S2. Prepare a sucrose solution with a mass fraction of 52% in the reaction vessel, then add citric acid to the reaction vessel and adjust the pH of the sucrose solution to 5.8;

[0059] S3. Place the reaction vessel in a water bath production structure for heating in a water bath. After the temperature of the sucrose solution is balanced, add the mixed solution in step S1 and keep stirring for saccharification reaction for 10 hours, then add fructose solution...

Embodiment 2

[0063] Fructose-oligosaccharides high in kestose, see figure 1 , its preparation process comprises the following steps:

[0064] S1. Place the 1-butyl-3-methylimidazolium hexafluorophosphate solution and the fructosyltransferase in the first mixing part and the second mixing part respectively, and then import them into the matching connecting barrel after standing for treatment , start the motor, drive the drive connecting shaft and the mixing connection frame to fully mix, and let it stand at 4°C for 7 hours;

[0065] S2. Prepare a sucrose solution with a mass fraction of 54% in the reaction vessel, then add citric acid to the reaction vessel and adjust the pH of the sucrose solution to 6.0;

[0066] S3. Place the reaction vessel in a water bath production structure for heating in a water bath. After the temperature of the sucrose solution is balanced, add the mixed solution in step S1 and keep stirring for saccharification reaction for 11 hours, then add fructose solution t...

Embodiment 3

[0070] Fructose-oligosaccharides high in kestose, see figure 1 , its preparation process comprises the following steps:

[0071] S1. Place the 1-butyl-3-methylimidazolium hexafluorophosphate solution and the fructosyltransferase in the first mixing part and the second mixing part respectively, and then import them into the matching connecting barrel after standing for treatment , start the motor, drive the drive connecting shaft and the mixing connection frame to fully mix, and let it stand at 5°C for 8 hours;

[0072] S2. Prepare a sucrose solution with a mass fraction of 55% in the reaction vessel, then add citric acid to the reaction vessel and adjust the pH of the sucrose solution to 6.2;

[0073] S3. Place the reaction vessel in a water bath production structure for heating in a water bath. After the temperature of the sucrose solution is balanced, add the mixed solution after standing still in step S1, continue to stir the saccharification reaction for 12 hours, then ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com