Self-driven MSM ultraviolet detector and preparation method thereof

An ultraviolet detector, self-driven technology, applied in the direction of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of low responsivity, low current, low collection efficiency, etc., and achieve the effect of separation promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

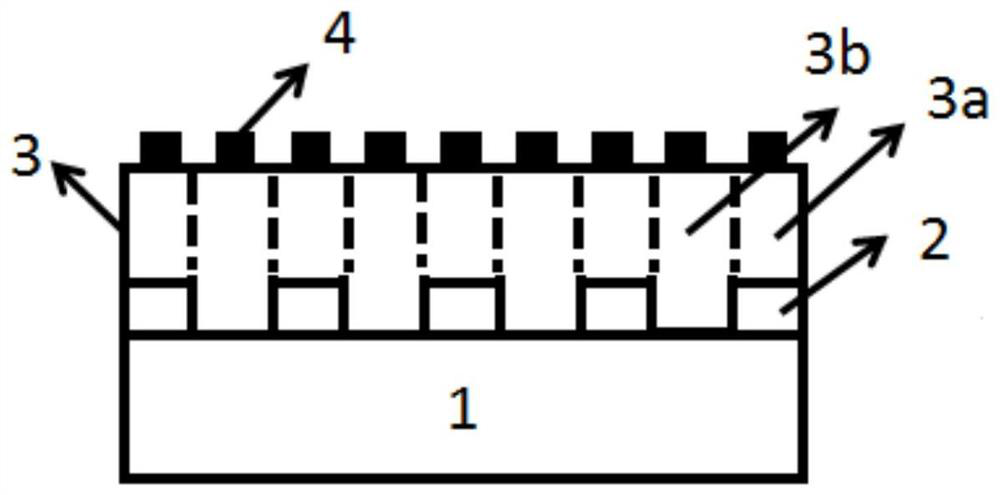

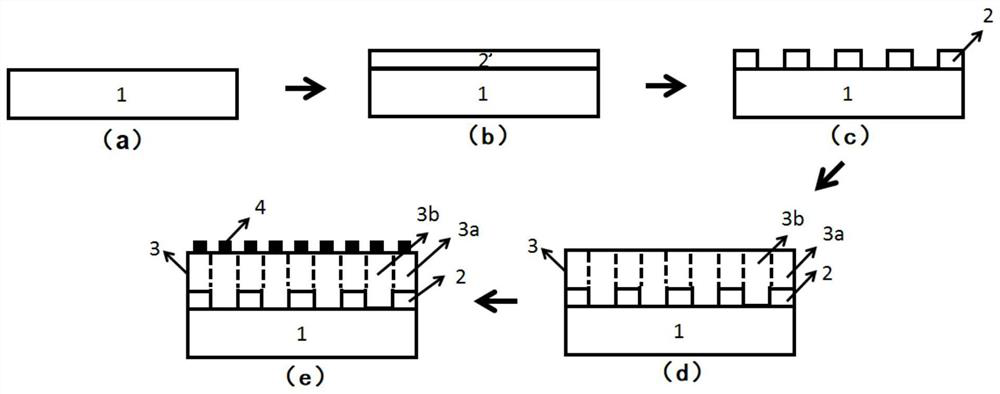

[0048] The present invention also provides a method for preparing a self-driven MSM ultraviolet detector, comprising the following steps:

[0049] a) depositing a low-temperature crystalline layer raw material on the surface of the substrate to obtain a low-temperature crystalline layer;

[0050] The material of the low-temperature crystalline layer is nitride of wurtzite structure; the deposition temperature is 300-950°C;

[0051] b) performing a patterning process on the low-temperature crystal layer to obtain a substrate with a patterned low-temperature crystal layer on the surface;

[0052] c) performing high temperature epitaxial growth on the surface of the substrate obtained in step b) to obtain a high temperature epitaxial layer;

[0053] The material of the high-temperature epitaxial layer is a nitride of wurtzite structure, and the temperature of the high-temperature epitaxial growth is 1000-1200° C.;

[0054] The high-temperature epitaxial layer epitaxially obtain...

Embodiment 1

[0069] To prepare a self-driven MSM UV detector, the specific steps are as follows:

[0070] a) A 20nm AlN low temperature crystalline layer was deposited on a 2-inch flat sapphire based on MOCVD technology; wherein, the deposition temperature of the crystalline layer was 850°C, the deposition pressure was 150torr, and the aluminum source used for the deposition was trimethylaluminum (TMA). ), the nitrogen source is ammonia (NH 3 ).

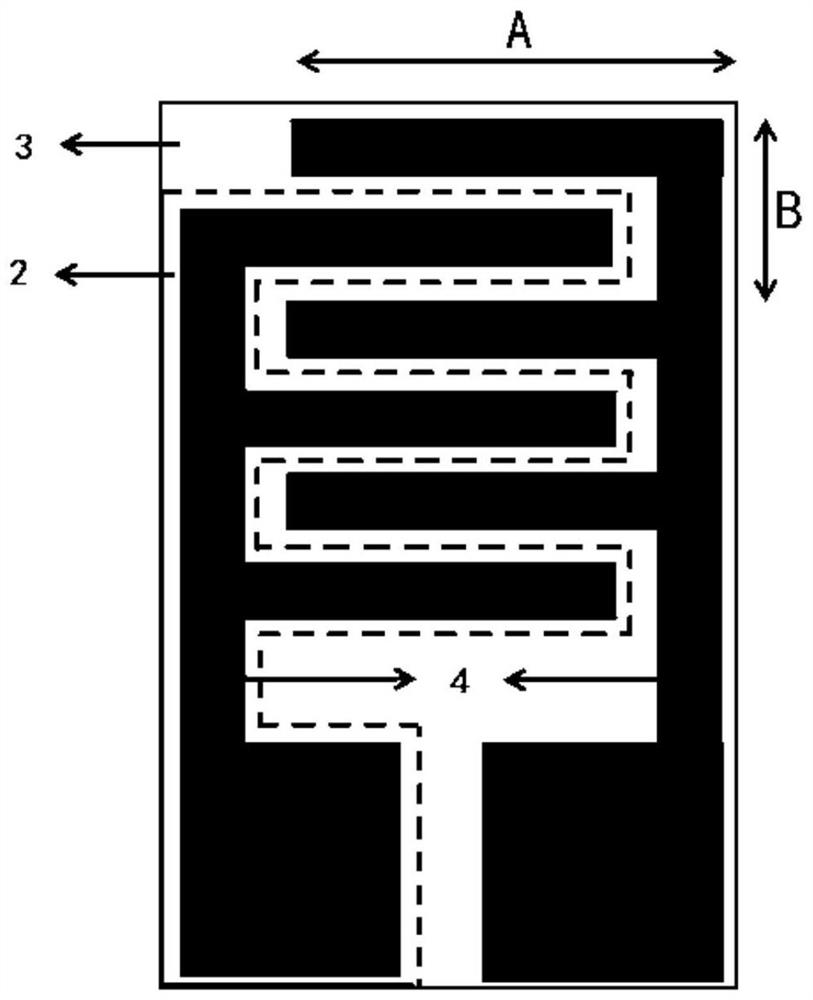

[0071] b) Spin-coat 1.5 μm thick photoresist on the surface of the substrate deposited with the low-temperature crystalline layer, use a contact exposure apparatus to expose and develop, and form an interdigitated patterned structure on the photoresist layer; wherein, the exposure time is 8 seconds, the development time is 30 seconds; the interdigital structure period values are 16 and 24 microns, respectively, and the length is 500 microns.

[0072] c) Based on plasma etching, remove the AlN low temperature crystalline layer of the exposed p...

Embodiment 2

[0078] a) A 50nm AlN low-temperature crystalline layer was deposited on a 2-inch flat sapphire based on magnetron sputtering technology; wherein, the deposition temperature of the crystalline layer was 400°C, and the deposition pressure was 3×10 -5 Pa, the aluminum source used for deposition is metal aluminum target, and the nitrogen source is nitrogen (N 2 ).

[0079]b) patterning the surface of the sapphire substrate deposited with the AlN low temperature crystalline layer by step exposure technology to form an interdigitated patterned structure; wherein the interdigitated structure has a period value of 16 microns and a length of 500 microns.

[0080] c) depositing a Ti etching barrier layer with a thickness of 50 nm; etching the lower AlN low-temperature crystalline layer based on wet etching technology; wherein, the etchant used is 3 mol / L KOH aqueous solution, and the etching temperature is 70°C; after the etching, use deionized water to clean the sample, and then use H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com