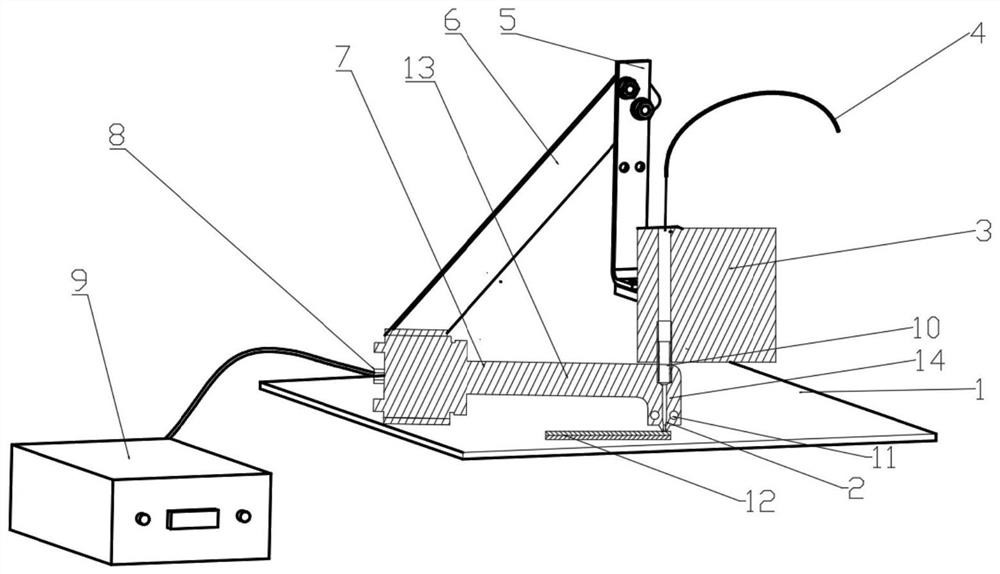

Ultrasonic-assisted continuous fiber reinforced thermoplastic resin 3D printing device and method

A technology of reinforced thermoplastic and continuous fiber, applied in the field of 3D printing, can solve the problems of weak ultrasonic effect, poor quality of fiber impregnation, and low bonding strength between layers, and achieve good interface bonding, reduced porosity, and fewer pores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0040] The above-mentioned ultrasonic auxiliary continuous fiber reinforced thermoplastic resin 3D printing device and 3D printing method are adopted, wherein the specific parameters are:

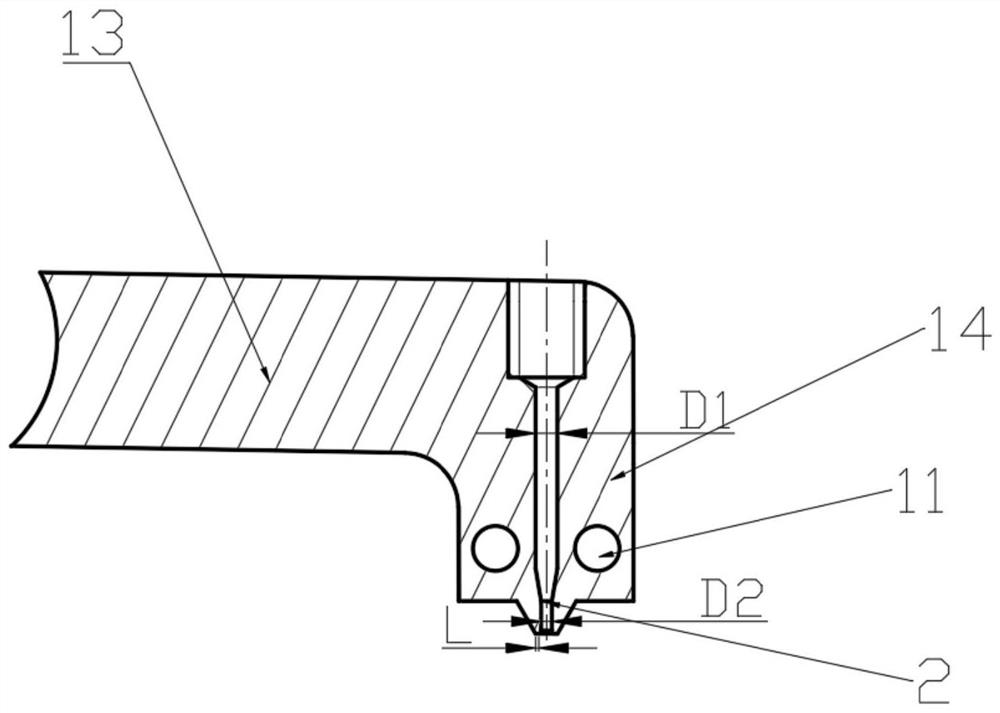

[0041]The printing parameters are selected as follows: printing speed 5mm / s; printing temperature is 280°C; printing layer thickness is 0.4mm; print line spacing is 1.0mm; printing material is continuous glass fiber reinforced nylon 6 prepreg, silk diameter is 0.8mm; the upflow channel diameter of the printing nozzle is 2mm, the downflow diameter D2 is 0.8mm, the rounded angle treatment at the outlet, and the width of the edge of the printing nozzle L is 1mm.

[0042] The parameters of the ultrasonic device are: the ultrasonic frequency is 15kHz, and the ultrasonic vibration amplitude is 60μm.

[0043] After testing, the bending strength, tensile strength, interlayer shear strength and porosity of the continuous glass fiber reinforced nylon 6 composite specimens can reach 321MPa, 207MPa, 32MPa ...

specific Embodiment 2

[0045] The above-mentioned ultrasonic auxiliary continuous fiber reinforced thermoplastic resin 3D printing device and 3D printing method are adopted, wherein the specific parameters are:

[0046] The printing parameters are selected as follows: printing speed 5mm / s; printing temperature is 280°C; printing layer thickness is 0.5mm; print line spacing is 1.0mm; printing material is continuous carbon fiber reinforced nylon 6 prepreg, wire diameter is 1.0mm, printing nozzle upflow diameter D1 is 2.5mm, downflow diameter D2 is 1.2mm, rounded at the outlet, printing nozzle edge width L is 1.5mm.

[0047] The parameters of the ultrasonic device are: the ultrasonic frequency is 30kHz, and the ultrasonic vibration amplitude is 50μm.

[0048] After testing, the bending strength, tensile strength, interlayer shear strength and porosity of the continuous carbon fiber reinforced nylon 6 composite specimens can reach 518MPa, 376MPa, 38MPa and 1.6% respectively, while the bending strength, tens...

specific Embodiment 3

[0050] The above-mentioned ultrasonic auxiliary continuous fiber reinforced thermoplastic resin 3D printing device and 3D printing method are adopted, wherein the specific parameters are:

[0051]The printing parameters are selected as follows: printing speed 5mm / s; printing temperature is 415°C; printing layer thickness is 0.5mm; printing line spacing is 1.0mm; printing material is continuous carbon fiber reinforced polyetheretherketone prepreg, the diameter of the wire is 1.2mm, the upflow channel diameter of the printing nozzle is 3mm, the downflow diameter is 1.5mm, the rounding at the outlet is rounded, and the width of the edge of the printing nozzle L is 2mm.

[0052] The parameters of the ultrasonic device are: the ultrasonic frequency is 50kHz, and the ultrasonic vibration amplitude is 40μm.

[0053] After testing, the bending strength, tensile strength, interlayer shear strength and porosity of the continuous glass fiber reinforced polyetheretherketone composite specimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com