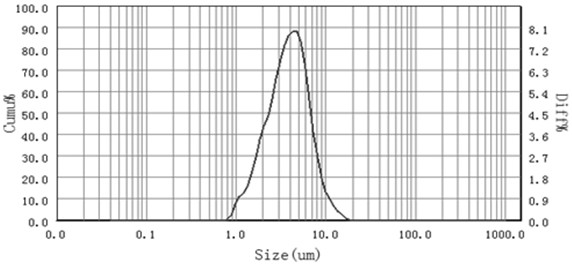

Silica wet gel with narrow particle size distribution and preparation method and application thereof

A technology of silicon dioxide and particle size distribution, applied in chemical instruments and methods, cosmetic preparations, silicon compounds, etc., can solve the problems of insufficient toothpaste consistency, uneven particles, strong gritty feeling, etc. The effect of uniform diameter distribution and moderate gritty feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

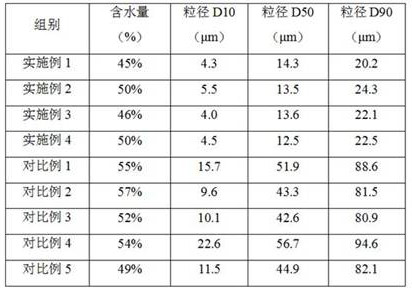

Embodiment 1

[0035] Example 1 Silica wet gel with narrow particle size distribution of the present invention and its preparation

[0036] S1, add water glass with a modulus of 3 to dilute, dissolve and age for 6h, take the water glass after the ageing treatment and add water to dilute to configure a sodium silicate solution with a concentration of 1.0mol / L, for standby use; the preparation concentration is 3.5mol / The sulfuric acid solution of L and the sodium sulfate solution with mass percent concentration of 5% are for subsequent use;

[0037] S2, add 10m to the reaction tank 3 The sodium sulfate solution was heated to 55°C, and the sulfuric acid solution was added dropwise under stirring until the pH value was 2.0, and the sodium silicate solution and the sulfuric acid solution were added dropwise at the same time, and the process pH was maintained at 2.0;

[0038] S3, sodium silicate solution was added to 6m 3 When adding 20Kg of sodium dodecylbenzenesulfonate, continue to add sodiu...

Embodiment 2

[0043] Example 2 Silica wet gel with narrow particle size distribution of the present invention and its preparation

[0044] S1. Add water glass with a modulus of 3 to dilute, dissolve, and age for 6 hours. Take the water glass after the ageing treatment and add water to dilute it into a sodium silicate solution with a concentration of 1.2 mol / L. The sulfuric acid solution of L and the sodium sulfate solution whose mass percentage concentration is 4.5% are for subsequent use;

[0045] S2, add 11m to the reaction tank 3 The sodium sulfate solution was heated to 50°C, and the sulfuric acid solution was added dropwise under stirring until the pH value was 2.4, and the sodium silicate solution and the sulfuric acid solution were added dropwise at the same time, and the process pH was maintained at 2.4;

[0046] S3, sodium silicate solution was added to 6m 3 When adding 20Kg of sodium dodecylbenzenesulfonate, continue to add sodium silicate solution and sulfuric acid solution dro...

Embodiment 3

[0051] Example 3 Silica wet gel with narrow particle size distribution of the present invention and its preparation

[0052] S1. Add water glass with a modulus of 3 to dilute, dissolve and age for 7h, take the water glass after the ageing treatment and add water to dilute it into a sodium silicate solution with a concentration of 1.0 mol / L, for subsequent use; the preparation concentration is 3.5 mol / The sulfuric acid solution of L and the sodium sulfate solution with mass percent concentration of 5% are for subsequent use;

[0053] S2, add 10m to the reaction tank 3 The sodium sulfate solution was heated to 52°C, and the sulfuric acid solution was added dropwise under stirring until the pH value was 1.8, and the sodium silicate solution and the sulfuric acid solution were added dropwise at the same time, and the process pH was maintained at 1.8;

[0054] S3, sodium silicate solution was added to 6m 3 When adding 30Kg of sodium dodecylbenzenesulfonate, continue to add sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com